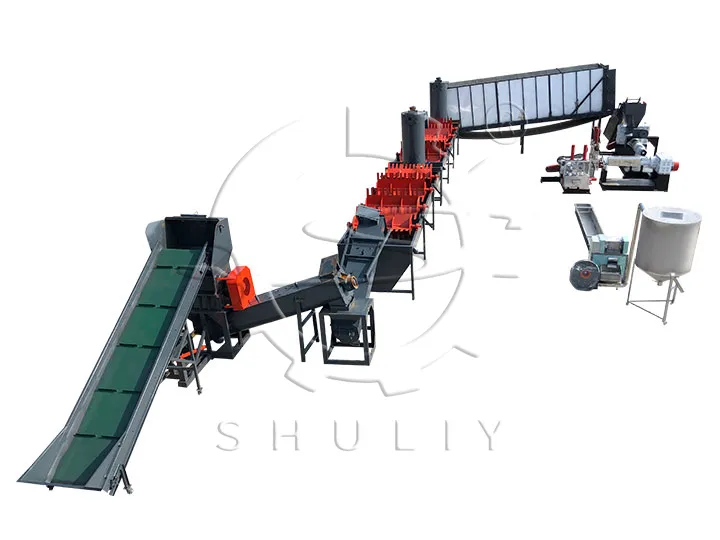

The plastic pelletizing line is a crucial piece of equipment that converts various rigid plastic waste into high-quality recycled pellets. It can be tailored to meet the needs of factories of all sizes.

- Capacity: 100~500kg/h

- Raw Materials: Rigid plastics, such as drums, pipes, etc.

- Final Products: pellets

- Application Objects: Plastic recyclers and manufacturers

Spotlights of Shuliy Plastic Pelletizing Line

Raw Material And Products Of Plastic Pelletizing Line

The rigid plastic pelletizing line can process all kinds of PP PE HDPE rigid plastic raw materials into recycled pellets.

Raw materials:

- Post-consumer Materials: Hard plastic waste, such as plastic drums, tubes, plastic pots, etc. made of PP, PE, HDPE, PVC, ABS, etc.

- Post-industry Materials: Edge materials generated in the industrial production process, discarded plastic products molds, etc.

Read: A step-by-step Guide about How is HDPE Recycled

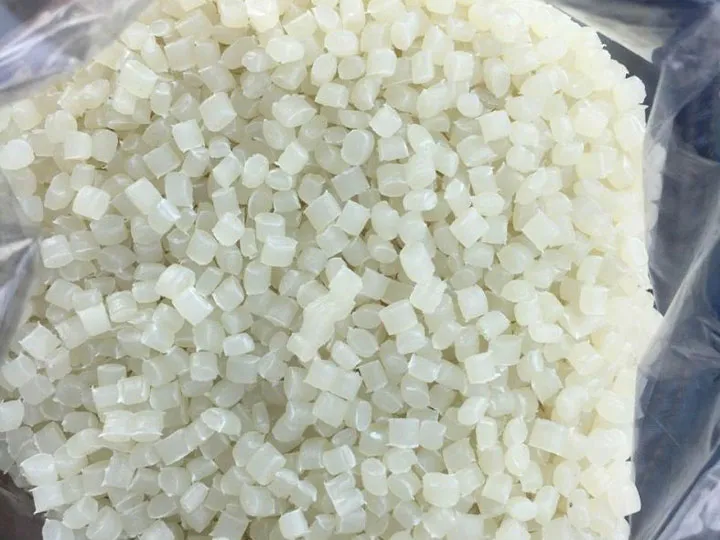

Final Products:

- Through the plastic pelletizing line, these raw materials are melted, extruded, cut into granules, and cooled to become recycled pellets.

- These recycled pellets can be widely used in the manufacture of various plastic products.

Plastic Recycling Plant Workflow

Crushing

Crushing is the first step in the plastic pelletizing line. Waste plastics are crushed through the hard plastic crusher, which breaks large pieces of plastic material into smaller particles or flakes in preparation for subsequent processing.

The blades used to cut the material are made of 60Si2Mn, which is very durable. What’s more, the clearance between the moving blade and the fixed blade of the hard plastic crusher is adjustable. The larger the selected clearance setting, the larger the resulting plastic particles.

Washing

The crushed plastic flakes usually contain impurities and therefore need to be cleaned. In the plastic rinsing tank, the plastic pieces are cleaned by water flow to remove dirt, grease, residue, etc. on the surface to ensure the purity and quality of the plastic granules.

Our plastic rinsing rank is generally from 10 meters to 30 meters long. The different sizes of tanks have different efficiency. And the specific length can be selected by customers according to their needs.

Drying

The cleaned plastic pieces need to be dewatered and dried to remove the moisture on their surface and inside. The horizontal drying machine removes water from plastic granules by rotating at high speed, etc., to make them reach a certain dryness and prepare them for the subsequent pelletizing process.

Depending on the speed of your washing line, you can choose the quality of the drying machine. In general, one is enough.

Pelletizing

The dried plastic pieces are conveyed into the plastic pelletizer. Here, the plastic granules are heated and melted by the action of heat and pressure and extruded through the die to form plastic strips of the required size.

There are three different heating devices: electromagnetic heating, ceramic heating, and iron heating. Among them, the most recommended method is electromagnetic heating for its highest efficiency.

Cooling

After plastic pelletizing, long strips of material may be at a high temperature due to the heat generated during processing, and cooling treatment is required to prevent the plastic strips from clumping or deforming. Cold water in the cooling tank can effectively reduce the temperature of the plastic and make it cool and solidify quickly.

The cooling tank is made of stainless steel 304 sink, which is durable and user-friendly.

Cutting

The final step is to cut the cooled pellets to obtain the desired particle size and shape. Plastic pellet-cutting machines usually use rotating blades or cutting devices to cut the plastic granules into small, uniform particles to meet specific customer requirements or product specifications.

Our automatic silent hob pelletizer is suitable for pelletizing after pelletizing and drawing. What’s more, it is uniform, simple, durable, and cost-effective.

How to Start Your Business with Shuliy Machinery?

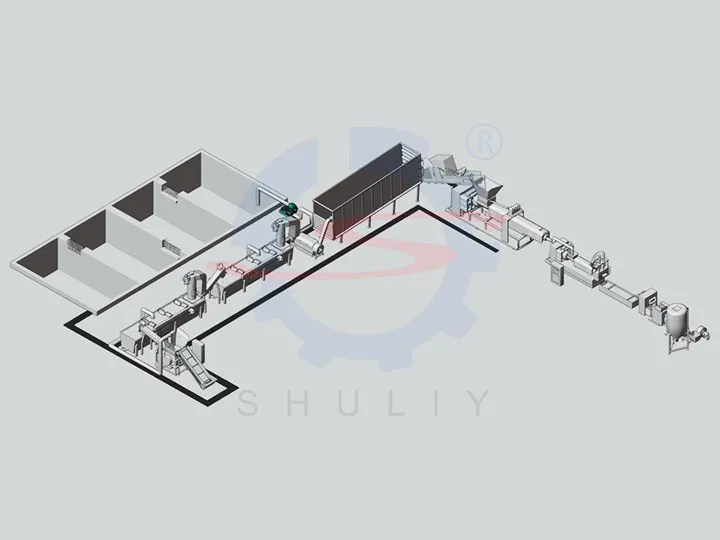

Plant Design

Take an example of a medium-sized hard plastic recycling line, it needs the following requirements:

- Workers Quantity: 8~10 workers

- Site requirement: 1000~3000 square meters

- Layout Design: Sample images are shown below. If you are interested, please send us your production requirements, and we will help you plan the most suitable hard plastic recycling line!

Pre-shipment Preparation

A video of the test run is usually sent to the customer before dispatch to ensure there are no problems with the machine. And the following video demonstrates the workflow of the entire HDPE pelletizing line.

Differences Between Hard Plastic Pelletizing Line and Soft Film Pelletizing Line

Different Raw Materials

- Plastic pelletizing line for hard PP PE HDPE waste is usually used to process rigid plastics, PP PE flakes, and HDPE plastics, such as plastic buckets, plastic pots, etc.

- The plastic film pelletizing line is specially used to process soft PP PE plastic film waste, such as plastic bags, woven bags, agricultural films, etc.

Different Feeding Methods

- A rigid plastic recycling granulating line can generally adopt manual or semi-automatic feeding mode, the operator directly puts the plastic raw materials into the plastic pelletizing machine.

- A plastic film recycling line usually needs to be equipped with an automatic feeder, because film plastic raw materials are thin and easy to deform, automatic feeders can ensure the uniform supply of raw materials to improve production efficiency and quality of finished products.

Different Drying Methods

- PP PE film plastic pelletizing line usually uses the vertical dryer for drying.

- While the PP PE flake recycling line often uses a horizontal dewatering machine for drying, to adapt to different plastic characteristics and processing needs.

Why Choose Shuliy Plastic Pelletizing Machine?

High Quality

The key parts of the machine are made of high-quality steel, which is very durable and reliable. All of our machines are made to standard. Especially, our reducers are nationally certified. You can rely on our products without any worries.

Scientific Design

Our plastic granulator is the fifth-generation waste plastic granulator with a double-stage screw. 38CRMOALA nitrided steel screws can be customized according to customer requirements. Other machines are also user-friendly, such as the automatic feeding machine, the automatic silent hob pelletizer, and so on. The above professional design can keep the equipment running efficiently and guarantee the output of high-quality finished plastic particles.

Visiting Our Plastic Pelletizing Plant!

Shuliy is a professional plastic granulating line supplier, dedicated to providing customers with high-quality plastic recycling equipment and solutions. We have an advanced production process and technical team to meet different customers’ needs. We sincerely welcome customers to visit our plastic recycling factory to witness our production process and equipment quality and experience our professional service.

Plastic Pelletizing Line Price

Are you curious about the price of a plastic flake pelletizing line? The cost of plastic pelletizing production lines is related to various factors, including production capacity, equipment specifications, technical features, etc. Generally speaking, the plastic pelletizing lines budget will differ according to your specific needs. If you are interested in our products, please contact us, and we will provide detailed quotations and technical support according to your needs.