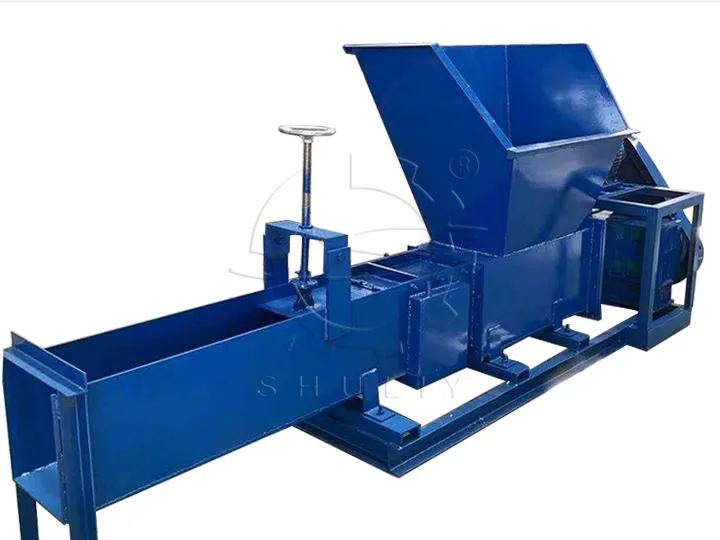

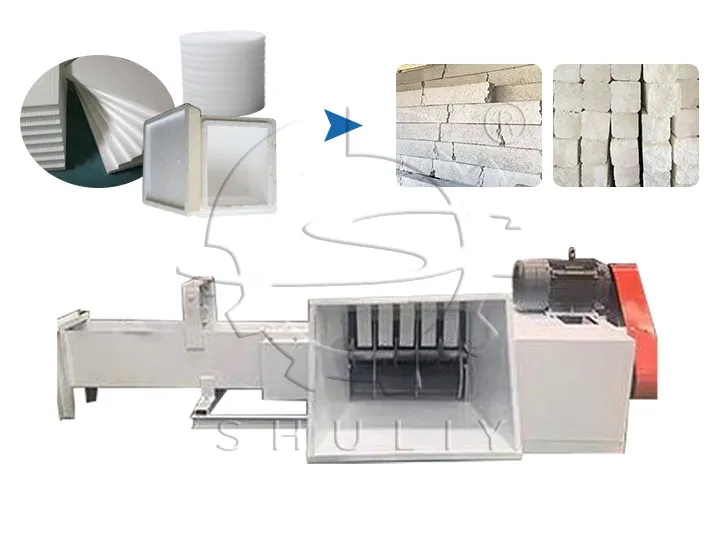

Recently, a plastic recycling plant manager from Malaysia purchased two vertical EPS foam compactors from Shuliy to improve recycling efficiency. Foam compactor machines are specifically designed to compress foam materials. Shuliy EPS foam cold pressing styrofoam densifiers are easy to operate, highly productive and effective in gradually compressing foam into more compact shapes, thus saving storage space and transportation.

Malaysia customer’s background and needs

This customer specializes in plastic recycling and has his own plastic recycling plant. He is looking to expand his business and is currently planning to acquire two additional EPS foam compactors to increase productivity and processing capacity to cope with the growing market demand and optimize the existing production process.

Why do Malaysian customers work with Shuliy?

Shuliy EPS foam compactors meet customer needs

First and foremost, Shuliy’s foam compactor machines are perfectly suited to meet the needs of our customers. These machines are specifically designed to process EPS foam, compressing it into blocks that are easy to transport and store for subsequent reuse or disposal. This meets the customer’s business needs and allows them to be more efficient in their plastic recycling efforts.

Shuliy offers full support

Secondly, Shuliy does not just provide recycling equipment, but a full range of support and services. Before the customer chose the equipment, Shuliy’s team provided them with detailed technical information, pictures and videos so that they could fully understand the working principle and performance characteristics of the EPS foam compactor. In addition, Shuliy’s team answered the customer’s questions in a timely manner, helping them make an informed decision.

Plastic recycling factory visit

Before deciding to cooperate, the customer sent a delegation to Shuliy’s factory for a site visit. Through this visit, the customer had a more comprehensive understanding of Shuliy’s production process and quality control, which further strengthened their sense of trust.

Successful delivery of foam compactor machine

After thorough communication and cooperation between both parties, Shuliy’s EPS foam compactors were successfully shipped to Malaysia. Once the vertical EPS foam compactors were put into operation, they showed excellent performance and stable working conditions. They efficiently compressed EPS foam into compact blocks, greatly reducing the volume of plastic waste and improving recycling efficiency.

Feedback from satisfied customers

Shortly afterward, the customer sent Shuliy unsolicited feedback. They said that the EPS foam compactor supplied by Shuliy had greatly improved their production efficiency and enabled them to respond to market demands more easily. The customer also appreciated the professionalism and dedication of the Shuliy team and expressed their willingness to continue working together in the future.