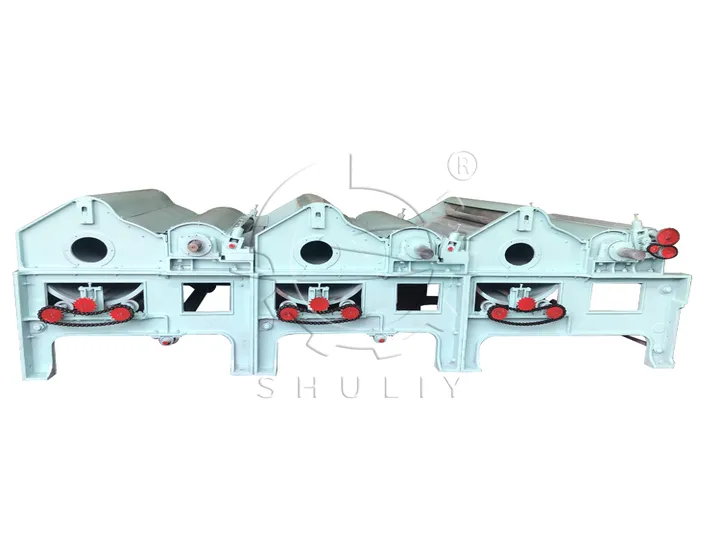

In the growing circular economy, textile waste is no longer a liability but a valuable asset. Our professional Cotton Waste Opening Machine is at the forefront of this transformation. Engineered specifically for the demanding needs of the textile recycling industry, it efficiently processes raw cotton waste and fabric scraps, converting them into clean, high-value fiber. This machine is a crucial first step for any serious fabric scrap recycling operation, enabling you to reduce landfill waste and create profitable new products.

From Low-Value Waste to High-Quality Fiber

Our powerful textile opening machine is designed for versatility, capable of handling a wide spectrum of post-industrial and pre-consumer textile materials.

- Input Materials: It effectively processes ginning waste, yarn scraps (hard waste), fabric offcuts, denim clippings, garment factory waste, and other cotton-rich textile residues.

- Output Product: The result is clean, lofty, and well-opened cotton fiber. This recycled fiber is ideal for re-spinning into new yarn (open-end spinning), producing non-woven fabrics, and serving as premium filling material for insulation, furniture, and other applications.

Why Invest in Our Cotton Waste Opening Machine?

Choosing the right equipment is critical for success. Our machine offers distinct advantages that translate into better quality and higher returns.

- Unmatched Cleaning Performance: This machine is more than an opener; it functions as a high-efficiency fiber cleaning machine. Its design uses centrifugal force to separate heavy impurities like dust, dirt, and seeds from the fibers. The clean output significantly increases the value and usability of the recycled material.

- Optimized for High-Volume Production: Built with a robust frame and powerful motor, our machine delivers consistent, high-throughput performance. It is designed for continuous industrial use, minimizing downtime and keeping your production line moving efficiently.

- Advanced Fiber Protection: While aggressive opening is necessary, preserving fiber length is key to quality. Our machine’s rollers are equipped with scientifically designed metallic card clothing that gently teases fibers apart, minimizing damage and maintaining the integrity needed for strong yarns and durable non-wovens.

- Durable Engineering for Longevity: We use high-quality, wear-resistant steel for all critical components. This ensures a long service life with minimal maintenance, providing a reliable return on your investment.

How It Works: A Simple and Effective Process

The operational principle of our Cotton Waste Opening Machine is focused on efficiency and simplicity.

- Uniform Feeding: Raw material is evenly fed into the machine via a conveyor or manually.

- Primary Opening: The material first encounters a licker-in roller that performs the initial tearing and loosening.

- Refined Opening & Cleaning: It then moves to the main high-speed, toothed cylinder. Here, intense mechanical action fully separates the fibers while centrifugal force ejects impurities through specialized grids.

- Air Conveyance: The clean, fluffy fiber is then collected and transported by an air suction system to a baler or the next machine in the line.

Key Applications for Recycled Fiber

The high-quality fiber produced by our machine has numerous commercial applications, including:

- Open-End Spinning: Recycled cotton is blended with other fibers to produce new yarn for apparel, home textiles, and industrial fabrics.

- Non-Woven Fabric Production: Used to create felts and pads for automotive insulation, furniture padding, geotextiles, and mattress components.

- Filling Material: Serves as a cost-effective and sustainable filling for pillows, cushions, toys, and insulated jackets.

Technical Specifications

Select the model that best aligns with your production capacity and material type.

| Parameter | GM-1010 | GM-600 | GM-610 |

|---|---|---|---|

| Features | Single Roller Cleaning | Large Roller, Heavy-Duty | Multi-Function Combination |

| Capacity | 60 – 100 kg/h | 180 – 220 kg/h | 150 – 180 kg/h |

| Main Power | 5.5 KW | 18.5 KW | 7.5 KW |

| Main Roller Dia. | 250 mm | 600 mm | 350 mm |

| Dimension (L*W*H) | 1950*1500*1150 mm | 2600*1550*1300 mm | 2100*1500*1200 mm |

Upgrade Your Recycling Line Today

Invest in a machine that delivers tangible results. Our Cotton Waste Opening Machine is the reliable, high-performance choice for businesses looking to lead in the textile recycling market. Contact us for a detailed quote and expert consultation on how to integrate this machine into your workflow. We also provide fiber cutting machines