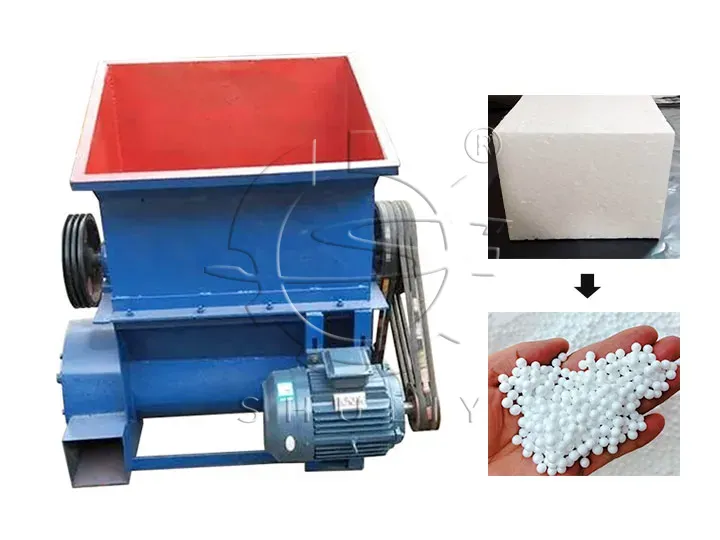

EPS hot melting recycling machine is a kind of equipment specially used for processing Expanded Polystyrene waste. It realizes the efficient use and resourceful treatment of waste EPS by crushing and melting the waste EPS foam products and finally converting them into lump materials. Its capacity ranges from 100kg/h to 250kg/h.

Why Shuliy Styrofoam Densifier?

Exquisite Design

The inclination angle of the feed inlet, intelligent temperature control, advanced screw melting technology, and other features are meticulously designed and crafted by professional scientists to ensure stable and safe production of high-quality foam blocks for subsequent processing.

User-friendly

The utilization of an automated system ensures that our hot melting machine is easy to operate and guarantees safety. And there is a safety switch that can be easily triggered, causing the machine to stop immediately.

Applicable to the Vast Majority of Factories

It can easily process the majority of discarded EPS plastic foam and has high utility value with low investment and high returns.

Customized Service

As a professional plastic machine supplier, we can provide the entire plastic recycling method and assist customers in choosing the most suitable one.

Application of EPS Foam Melter

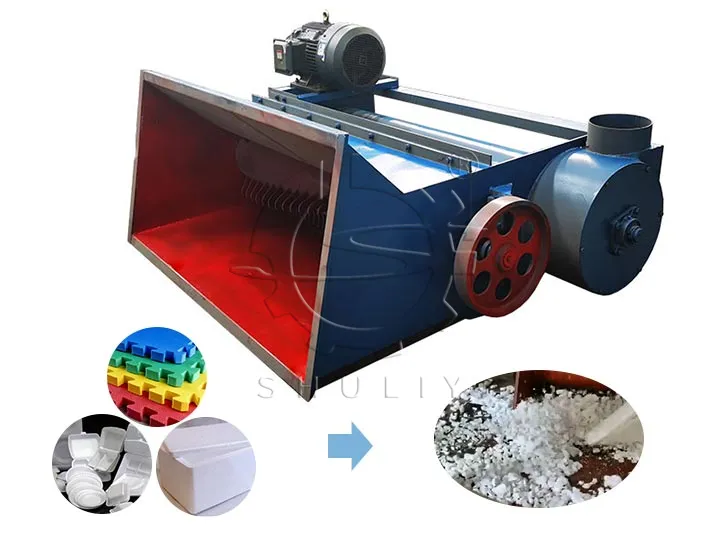

A foam crushing and lumping machine is a kind of equipment for efficiently processing various kinds of waste foams, which converts waste foams into recyclable lumps through mechanical crushing and hot pressing technology. This EPS hot melting recycling machine is widely used in the field of the following:

Raw Materials:

Recycling of Waste Foam Plastics: takeaway boxes, the inner liner foam of electronic product packaging, the protective foam in furniture packaging, packaging materials, building insulation materials, etc.

Usage:

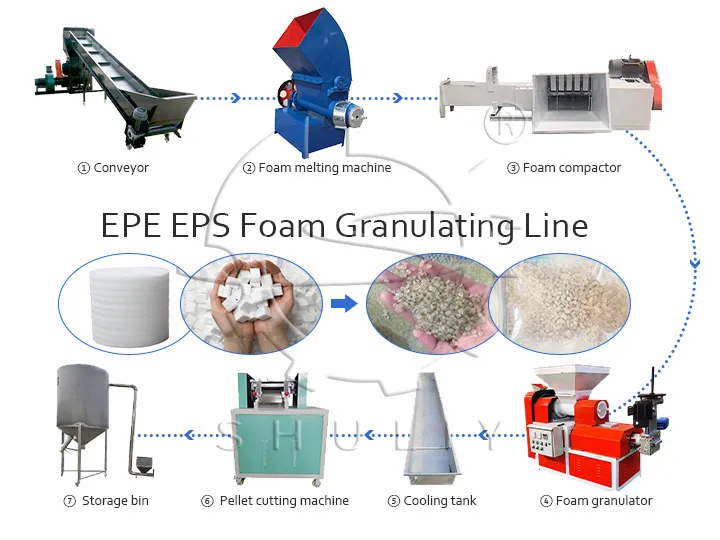

- Production of recycled plastic: The melted EPS foam can be further processed into recycled plastic and used to manufacture various plastic products such as plastic pellets and sheets.

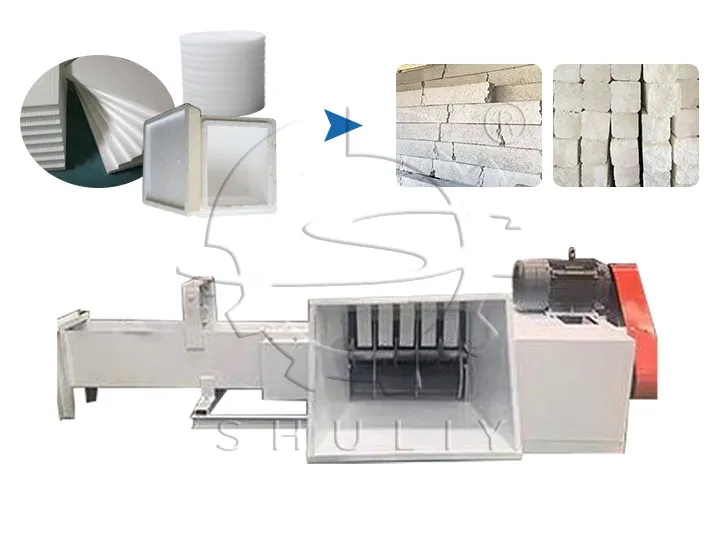

- Building insulation materials: The EPS material treated by hot-melt processing can be used to produce building insulation boards with excellent thermal insulation performance.

- Decoractive Materials: Melted EPS material finds application in producing lightweight and soundproof decorative elements such as ceiling tiles and wall panels.

- Packaging Materials: Recycled EPS material serves as a valuable resource for crafting diverse packaging materials designed to protect products during transportation.

In short, the utilization of a hot melter plays a crucial role in environmental preservation and resource recycling efforts by reducing waste volume, minimizing transportation costs, and enhancing resource reutilization rates—thus benefiting both environmental conservation endeavors and economic development initiatives significantly.

EPS Hot Melting Machine Parameters

| Raw material | Waste foam plastics, such as takeaway boxes, the inner liner foam of electronic product packaging, the protective foam in furniture packaging, packaging materials, building insulation materials, etc. |

| Final Product | Dense EPS blocks and sheets for subsequent pelletizing and the pellets can be used in the production of building insulation boards, decorative and packaging materials, etc. |

| Output | 100-250kg/h |

| Voltage | 380V, three-phase supply |

| Optional devices | EPS foam melting machine is typically applied in the EPS foam recycling line. It can match with an EPS foam compactor, pelletizer, and plastic pellet cutting machine. |

| Technical Assitance | One-year warranty with no extra costs and we can provide technical assistance at any time. |

The above parameters explain some basic information about the EPS hot melter, and the specific parameter comparisons for some popular hot melters are as follows:

| MODEL | SL-220 | SL-880 | SL-1000 |

|---|---|---|---|

| Size(mm) | 1500*800*1450 | 1580*1300*850 | 1900*1580*900 |

| Feed port size(mm): | 450*600 | 800*600 | 1000*700 |

| Configuration power(KW): | 15 | 18.5 | 22 |

| Inlet power(KW): | 3 | 3 | 3 |

| Capacity(KG/H): | 100-150 | 160-200 | 200-250 |

*CE certification available

Working Principle of EPS Hot Melting Recycling Machine

- Large blocks of waste EPS foam are fed into the hopper of the hot melter.

- High-speed blades rotate rapidly to cut plastic foam blocks into pieces.

- Utilizing advanced screw melting technology convert plastic pieces into liquid.

- The melted styrofoam ingots are extruded by the screw

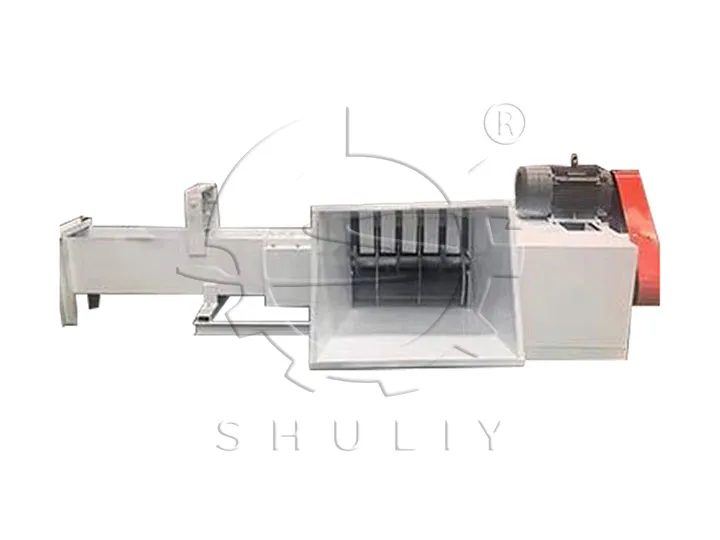

Structure of Styrofoam Hot Melter

The styrofoam melting machine consists of several key components. Here are some main parts and their description:

- Hopper: Where the plastic foams are fed into EPS hot melter. The wall of the feed inlet is tangent to the inner circumference of the barrel, which not only enlarges the cross-sectional area for material feeding but also facilitates smoother material entry into the melter.

- EPS Foam scrap crusher: The sharp stainless steel blades rotate rapidly, capable of processing 100-250kg of plastic per hour.

- Melting Chamber: Generate sufficient heat to melt the plastic. Utilizing screw technology, it can have rapid heating, long service life, and minimal heat loss.

- Compression System: Transports and compresses the melted EPS, reducing its volume.

- Control Panel: Allows operators to control and monitor the machine’s operations, which includes emergency stop buttons and alarms for safe operation.

Foam Melting Machine Price

Are you curious about the price of an EPS hot melting recycling machine? As a professional manufacturer of plastic foam densifiers, we offer competitive prices and can customize solutions according to your needs. With high efficiency and reliability, our recycling equipment can help you process foam waste and reuse resources. Contact us for detailed information and quotation, we are looking forward to providing you with high-quality service and equipment!