The Shuliy EPE EPS recycling machine is specially designed to transform waste plastic foam into high-quality pellets. It is suitable for all sizes of foam recycling plants. As a professional plastic recycling machinery supplier, we can provide customized machines based on your production needs.

- Capacity: 150kg/h~300kg/h

- Raw Material: EPE, EPS foams, etc.

- Final Products: High-quality granules

- Application Objects: Foam recyclers and manufacturers.

Key Features of the Shuliy EPE&EPS Foam Recycling Machine

High Efficiency

Foam recycling machine adopts advanced production processes and equipment, which can realize high-efficiency production, improve production efficiency, and reduce production cost. With the machine, waste plastic foam can reduce its volume by up to 90%. Whether from the point of plastic recycling or environmental production, our expanded polystyrene recycling machine is very conducive to our industrial production and daily life!

Customization

Our styrofoam recycling machines are usually flexible and can be customized to meet different types, specifications, and requirements for producing recycled pellets. The number and type of machines can be adjusted depending on the purpose and requirements of the production. Whether you are just starting in the plastics recycling business or want to improve the productivity of your existing equipment, feel free to contact us for customized solutions.

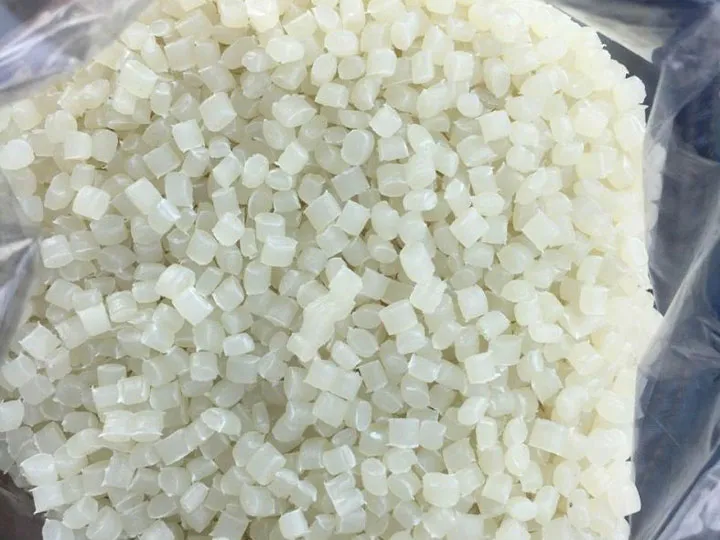

High-Quality Recycled Pellets

Through sophisticated production processes and strict quality control, the recycled pellets produced by the EPS recycling machine are of good quality and can meet different customers’ needs. The recycled foam can be used in numerous applications, such as the packaging industry, construction industry, craft materials, etc. Just through these simple operations, you can turn waste foam into treasure, and protect the environment while earning greater profits. What a multi-benefit the machine brings!

Considerate Service

We provide plant layout design, operation guides, a one-year warranty, on-site installation, etc. If you have any questions, please don’t hesitate to contact us. We’ll try our best to help you.

Using the Foam Recycling Machine Transform Raw Materials into What You Want

The styrofoam recycling machine is mainly used to process foam materials such as EPE and EPS.

- EPE foam is known for its soft texture and excellent cushioning properties, making it ideal for use in packaging materials and thermal insulation.

- EPS foam, conversely has high hardness and strength and is often used to make thermal insulation boxes, packaging boxes, and so on.

Through a series of processing steps, the foam recycling machine can regenerate these waste EPE and EPS foam materials and finally convert them into recycled pellets. The pictures are as follows:

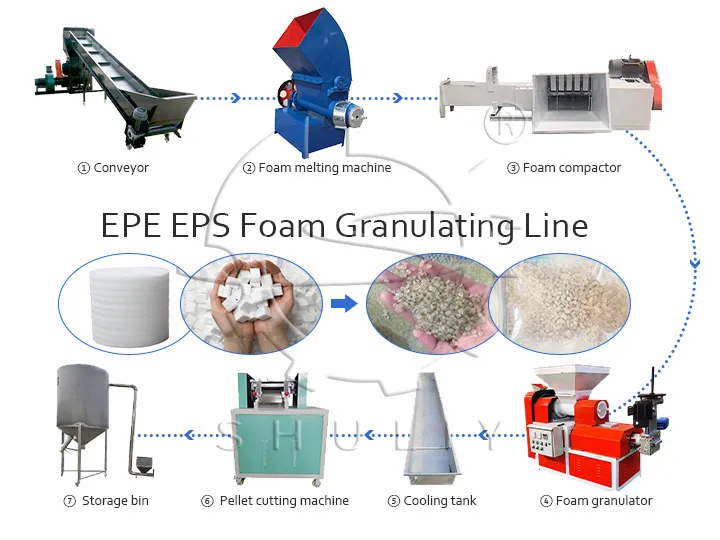

A Step-by-step Guide to Realize High-efficiency Recycling

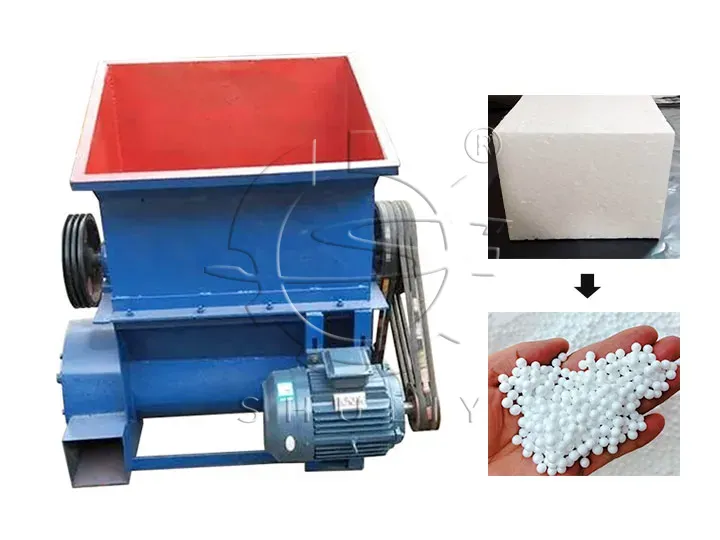

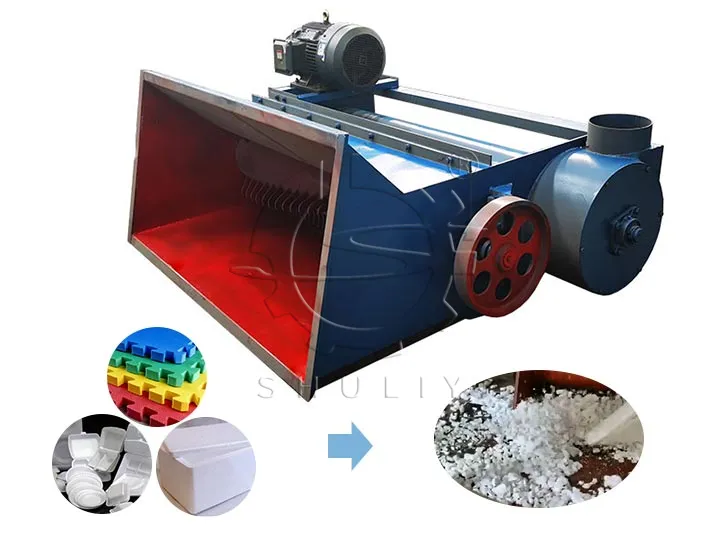

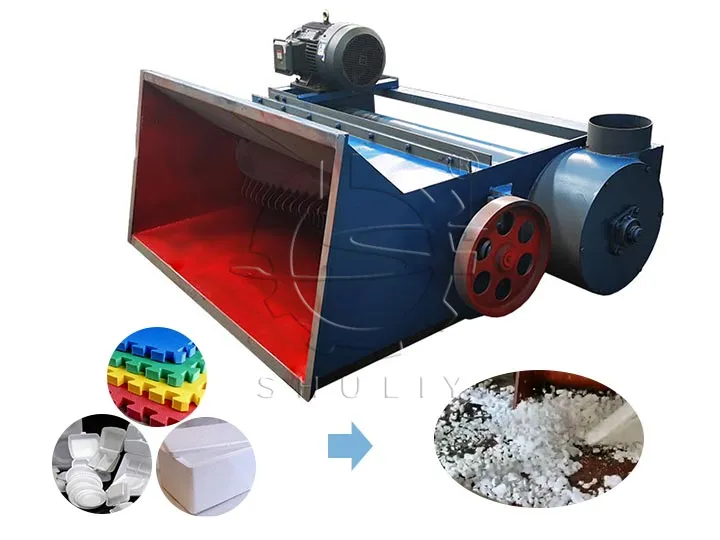

Step 1: Crushing

First, crushing is the starting part of the whole plastic foam recycling line. Waste foam products (such as foam boards, foam boxes, etc.) are fed into the foam cutting machine for crushing. The purpose of crushing is to break large pieces of foam material into small particles for subsequent handling and processing. The blades of the machine are made of 60 silicon-dimanganese, which is very durable.

- Capacity: 250~500kg/h

- Blades Material: 60 Si2Mn

- Function: Crushing large foam plastics into smaller pieces

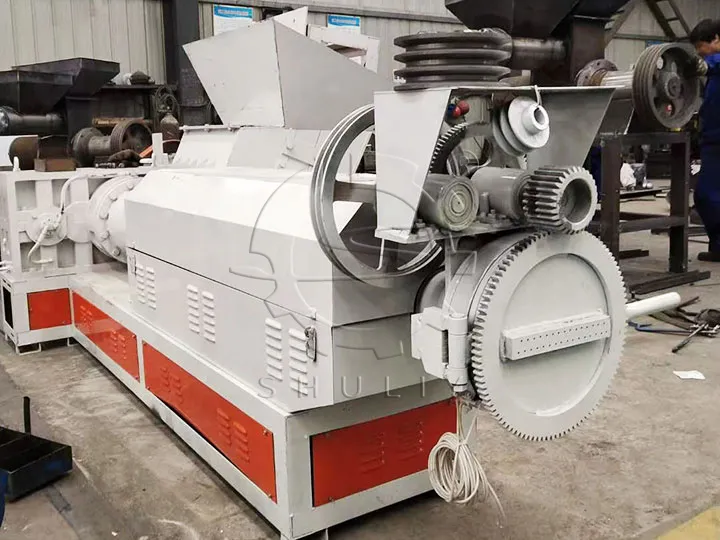

Step 2: Melting And Extrusion

The crushed pellets are fed into the plastic foam grinder, where they are heated and melted to turn the foam material into a molten state. The molten foam is then extruded through a mold into long plastic strips in the form of noodles. The whole heating process with high power and low energy consumption can effectively improve production efficiency.

- Types: EPS Pelletizer and EPE Pelletizer

- Capacity: 150~375kg/h

- Function: Transforming foam plastics into pellets

Step 3: Cooling

The extruded plastic strips are passed through the cooling tank for rapid cooling. This process helps the strips to cure quickly and maintain their shape. The large-capacity cooling tank is made of steel, which is very resistant.

- Length: 0.4*2.5m

- Materials: High-quality stainless steel

- Function: Cooling granules to keep shape

Step 4: Cutting

Finally, the cooled plastic strip is fed into the plastic pellet cutting machine, which cuts the plastic pellets into the desired size and shape as required. The cut foam particles can be directly packaged or further processed and utilized.

- Capacity: 150~280kg/h

- Power: 2.2~3.0KW

- Final Products: foam granules

Working Process Video

In this video, you can have a comprehensive overview of the EPE EPS foam recycling machine. If you have any questions, please feel free to contact us.

Related Foam Recycling Machine

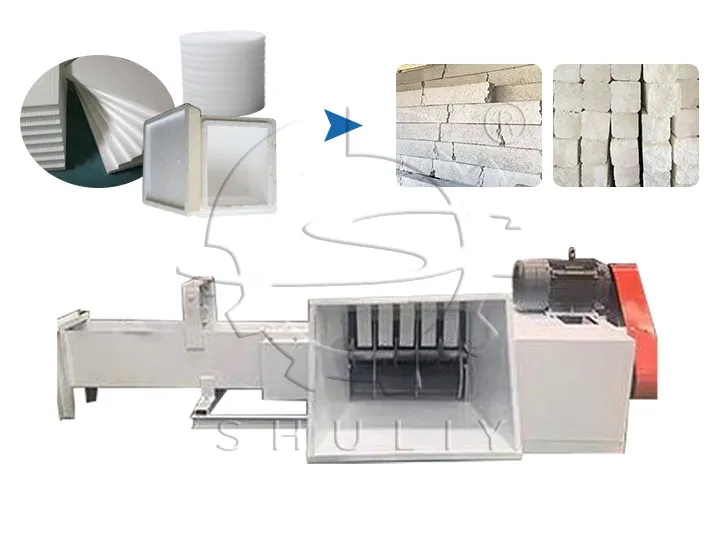

EPS Hot Melting Recycling Machine

EPS hot melting machine is mainly used for crushing waste foam products and heating them while crushing to make them lumped so that the foam material becomes uniform granular or lump material.

Foam Compactor Machine

Foam compressors are mainly used to cold press large volumes of foam into blocks for easy storage and transportation. What’s more, compressing plastic foam also can help to avoid resource waste. There are two types of foam compactors and Shuliy offers both vertical EPS foam compactors and horizontal EPS foam compactors. If you need any, please feel free to contact us.

Foam Recycling Machine Price

As a professional styrofoam recycling machine manufacturer, we offer a wide range of foam pelletizing line models and configurations, with prices varying by model, specification, and customization needs. Our EPE EPS foam recycling machines are reliable in quality and superior in performance, and are suitable for the recycling and pelletizing production of various foam materials. Whether you are a start-up or a large-scale producer, we have the optimal solution for your needs. Feel free to contact us for a detailed quotation and technical support!