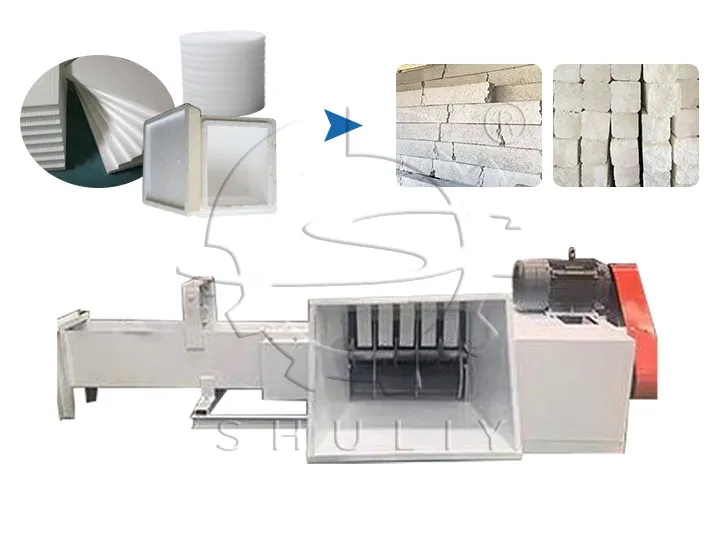

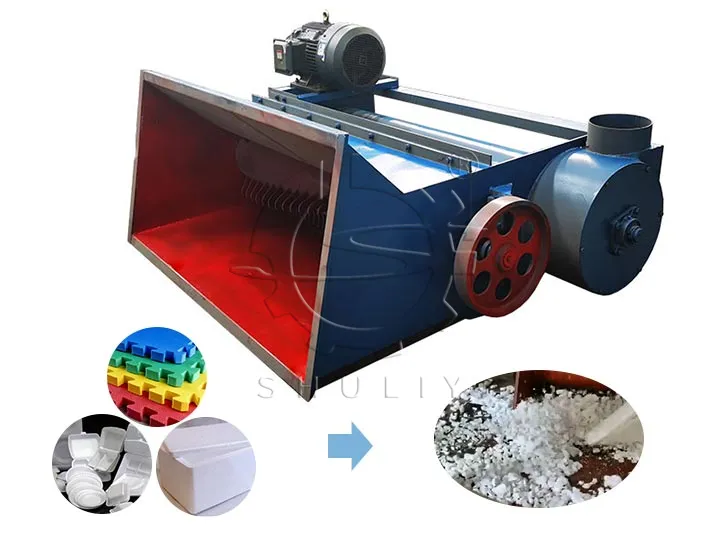

The Shuliy horizontal foam compactor machine is a specialized equipment for the compression of styrofoam, which is designed with advanced cold pressing technology to effectively reduce the volume of EPS foam waste, thus saving storage and transportation space and reducing disposal costs. As a professional manufacturer of plastic recycling machines, Shuliy also offers various models of vertical EPS foam compactors to meet customers’ recycling needs.

Advantages of Horizontal Foam Compressor Machine

- Volume Reduction to 40:1: Horizontal EPS foam compactors are capable of efficiently compressing loose foam or other materials into smaller volumes, thus saving storage and transportation space. This efficient compression capability makes it useful in foam recovery and reuse processes.

- Customized Machines: Horizontal foam compressor machines are available in a wide range of models and sizes that can be customized to meet a user’s specific needs. You can always contact us to customize different models and specifications of cold presses to meet the needs of different sizes of foam recycling lines.

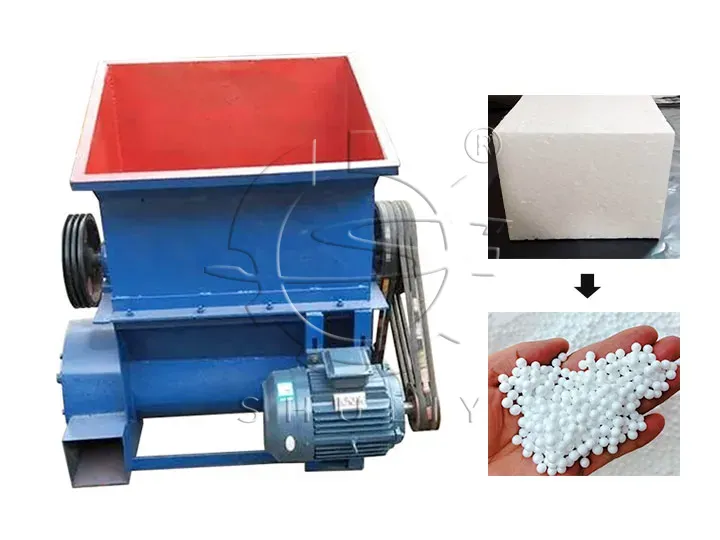

- Feature-rich: Shuliy horizontal styrofoam compactor machines are also equipped with a crushing function that allows the material to be crushed while it is being compressed, further improving the compression efficiency and ensuring the density and stability of the final compressed block.

- High Practicability: This foam compactor can used to recycle the vast majority of plastic foams and can satisfy many factories’ needs.

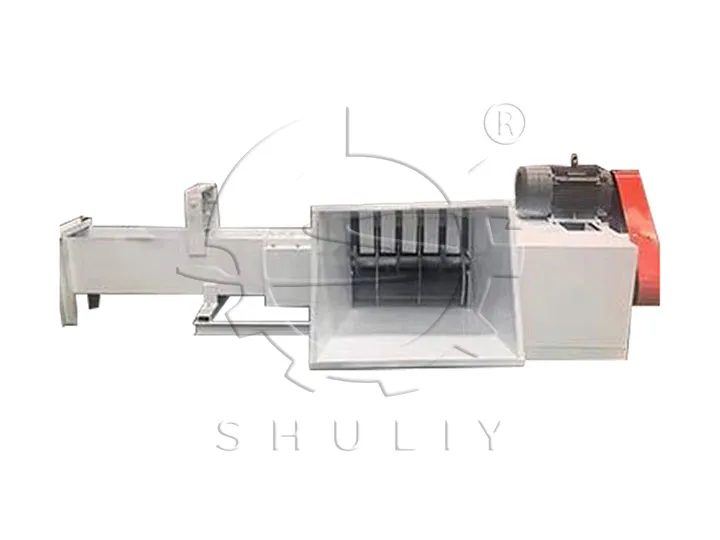

- User-friendly: The inlet of the horizontal foam cold press machine is parallel to the ground, making it convenient to feed materials. The automated system is simple and safe to operate.

- One-stop Service: As a plastic recycling specialist, Shuliy can provide technology assistance and various purchase methods according to your needs, such as instructions for installing and using the machine, as well as the appropriate model combinations for different production environments.

The Role of the Cold Pressing Machine

- The main function of the EPS foam cold pressing machine is to compress EPS foam, thereby reducing its volume.

- EPS foam is often widely used in packaging and filling materials, but its light and fluffy nature results in it taking up a relatively large amount of space.

- By using a foam compactor machine, EPS foam can be effectively compressed into a more compact form, saving space and reducing transportation costs.

Application of the Styrofoam Compactor

Raw Material

The raw materials of the EPS foam compactor are mainly from the waste plastic styrofoam. They are often used in the following fields:

- Discarded disposable lunch boxes

- the inner liner foam of electronic product packaging,

- the protective foam in furniture packaging

- packaging materials

- building insulation materials, etc.

Compacted Products

The volume of Styrofoam foam can be compressed to a ratio of 40:1, resulting in the production of dense plastic ingots. These compacted ingots possess high recycling value and find applications in electronics, toys, DVD cases, etc.

Parameters of EPS Foam Cold Pressing Machine

Model 300

- Machine size (mm): 3000*1700*900

- Inlet size (mm): 830*760

- Machine power (KW): 15

- Capacity (KG/H): 175

*CE certification available

Model 400

- Machine size (mm): 4600*2800*1200

- Inlet size (mm): 870*860

- Machine power (KW): 22

- Capacity (KG/H): 300

There are two types of EPS horizontal foam cold pressing machines, severally called SL-300 and SL-400. We can also provide other customized plastic recycling machines according to your needs. If you’re interested, please feel free to contact us.

Workflow of Horizontal EPS Foam Compactor

The workflow of the EPS cold compressor is relatively simple and efficient.

- First, the EPS foam to be compressed is dropped into the inlet of the machine.

- Then, the compression unit inside the machine starts to operate and compresses the EPS foam.

- During the compression process, the equipment applies appropriate pressure and temperature to ensure that the foam is compressed evenly and efficiently.

- Eventually, the compressed EPS foam is discharged through the equipment’s discharge port into a more compact block of material.

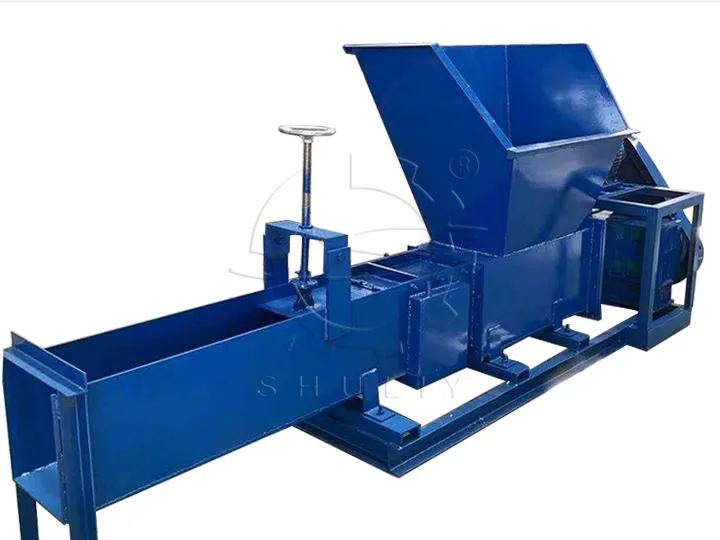

Differences Between Vertical and Horizontal Cold Compactors

Structural Differences

The main feature of a horizontal foam compactor machine is that the table is placed horizontally and the hopper is in a horizontal position during pressing. Its structure is relatively long and usually covers a large area. The Vertical EPS foam compactor is mainly characterized by the vertical placement of the worktable, and the hopper is in a vertical position during pressing. Its structure is relatively compact and covers a small area.

Feeding Method

The hopper of a horizontal EPS cold compactor is usually located at the bottom, and the material can enter directly from the bottom, which makes it easier to carry out continuous production because there is no need to stop and reload the material. The feeding method of the vertical EPS foam cold pressing machine is generally through the vertical hopper above to feed the raw materials directly into the machine, and then carry out the cold pressing operation on the vertical working table.

Applicable Scenarios

Because of their long structure, vertical EPS foam compressors are usually suitable for large factories that require a large amount of continuous production. Their horizontal layout also makes it easier for operators to operate and monitor. Horizontal EPS foam compressors are compact in structure and take up less space. Horizontal EPS foam compressors may be more suitable for smaller factories or places where a more flexible layout is needed. Because of their vertical layout, they are more flexible in space utilization and easy to move and install.

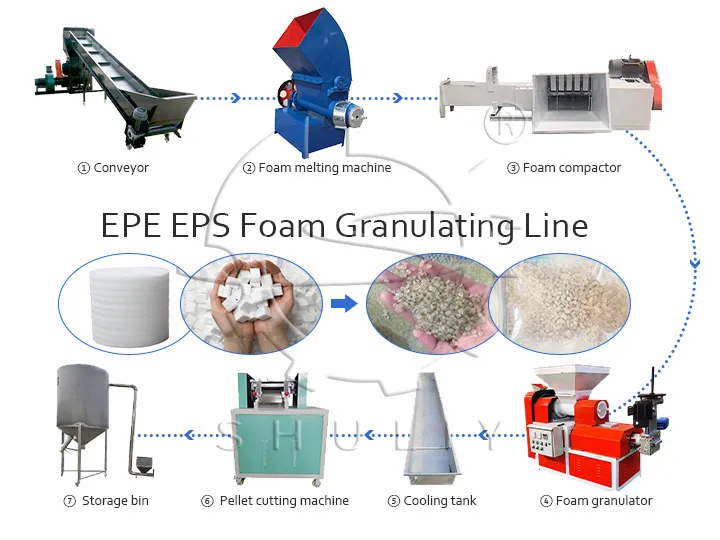

Related Machines

Shuliy provides an entire EPS recycling line, which consists of various recycling machines, such as an EPS hot melting machine, pelletizer, and so on. If you’re interested, please feel free to contact us.