PET recycling equipment Operational Precautions

Preparations before operation

- Check that all machines are properly placed and not leaning or suspended, to prevent them from collapsing or malfunctioning during operation, which could have negative consequences.

- Check that the power cord is properly connected and the PET recycling equipment is properly grounded to prevent electrical shock accidents.

- Be sure there is no overhead load on the machine.

- Try running the machine first to ensure that it operates properly.

During Operation

- Operators should wear protective goggles, gloves, and other safety equipment to prevent materials from splashing into their eyes and prevent other accidents.

- Do not put your body inside any PET recycling equipment.

- Make sure the feed is evenly distributed and do not put in too much material at once, exceeding the machine’s capacity.

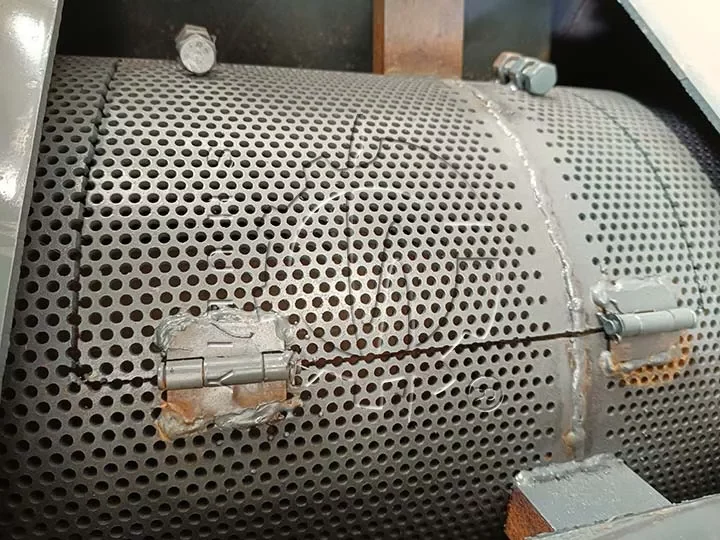

- Adjust the distance between the crusher blade and the sieve bottom to prevent too many fragments.

- When cleaning materials, make sure to give them enough washing time, and you can also add suitable cleaning agents to ensure that all stubborn stains are removed.

- The temperature of the hot washing tank should not be too high, usually maintained at 85-95 degrees Celsius. Higher temperatures can affect the adhesiveness of PET bottle flakes and prevent them from being made into fibers.

After Operation

- Turn off all power sources.

- Pay attention to cleaning the inner chamber of the washing machine and regularly disassemble and maintain it.

- If there is a malfunction, it is essential to immediately stop the machine, start troubleshooting, and have it repaired by a professional.

Daily Maintenance Guide

Daily Maintenance

- After utilizing, keep the device powered off and thoroughly clean the inner chamber, especially the parts that are prone to accumulating impurities, such as the screen and conveyor belt, etc.

- Regularly checking the wear and tear of the equipment and adding lubricating oil as instructed in the manual can help maintain its performance.

Annual Overhaul

- The equipment is inspected and maintained annually, including the electrical system, control system, and machinery.

- Focus on inspecting equipment that has been in use for a long time, and consider replacing or upgrading certain key parts to improve equipment efficiency.

Conclusion

By following these guidelines, you can effectively improve the efficiency of your PET recycling equipment. For specific installation and operation procedures for each device, please refer to the user manual or consult our after-sales personnel. Shuli will provide the most comprehensive technical support.