Good News! A customer from Ethiopia, who is involved in the plastic recycling business, customized plastic pelletizing recycling machines from Shuliy to process plastic waste more efficiently and produce high-quality plastic pellets. After careful commissioning and testing, the customized plastic pelletizing line has been successfully shipped to the customer’s factory!

Client background and requirements

This customer in Ethiopia owns a family-run plastic recycling business. They were already using plastic recycling granulator machines for plastic recycling production, but with the expansion of their business and technological advances, they urgently needed to update and upgrade their production line. The customer’s raw materials mainly consist of crushed and un-crushed hard materials, such as hard PP and PE plastics. They expect Shuliy plastic pelletizing recycling machines to produce high-quality pellets and further expand their business.

Customized recycling solutions from Shuliy

Shuliy, as a professional industrial plastic granulator manufacturer, understands the requirements of our customers. We customized plastic pelletizing recycling machines to meet the specific needs of our Ethiopian client, ensuring that it would be able to process waste plastics efficiently. In addition, we performed well in terms of lead time, completing the manufacturing and delivery of the recycling line on time to meet the customer’s urgent need to start the new line as soon as possible. Discounts and additional spare parts were offered to ensure the smooth operation and maintenance of the line.

Plastic pelletizing recycling machine parameters

| Item | Specifications | Item | Specifications |

| Plastic crusher | Model: SLSP-600 Motor power: 45 KW Capacity: 600-800kg/hour 10pcs knives Material of knives: 60Si2Mn With the safety cover | Plastic pelletizing machine | Host plastic granulatin machine Model: SL-180 Power: 55kw 2.8m screw Heat method: Ceramic heating Reducer: 280-Hardened gear reducer Second plastic granulating machine Model: SL-150 Power: 22kw 1.3m screw Reducer: 250-Hardened gear reducer Heat method: heating ring heating Screw material: 40Cr(High hardness and wear resistance) Barrel material: 45# steel |

| Plastic dryer | Power:7.5+0.75kw Dimension: 130*900*2150 Stainless steel shell, 304 stainless steel liner and screen | Plastic pellet cutting machine | 3kw Hob knives With inverter |

Below is the parameter information of some of the plastic pelletizing recycling machines customized to customers in Ethiopia. We offer various specifications of plastic recycling machines to meet different customers’ needs. If you need other specifications or have any questions, please feel free to contact us. Our team will be happy to provide you with the most professional service and support.

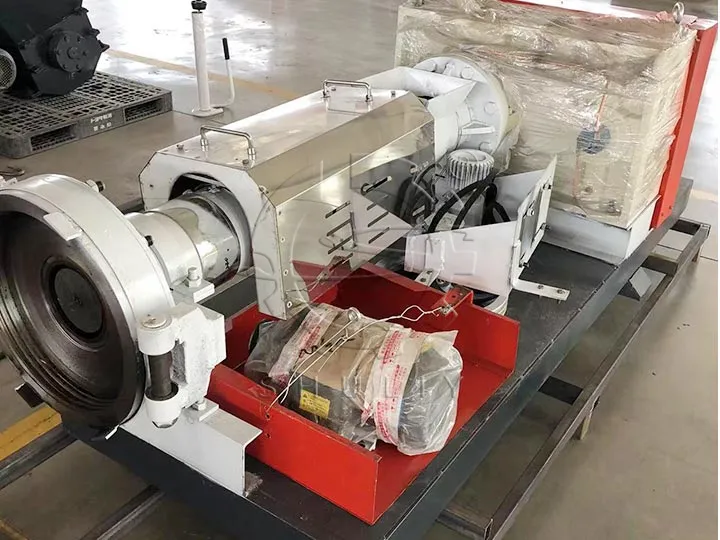

Successful shipment of pelletizing machine to the customer’s plant

After careful customization and thoughtful arrangement, plastic pelletizing recycling machines have been successfully shipped to the customer’s plastic granules extruder machine factory in Ethiopia. This state-of-the-art plastic recycling pelletizing line will provide the customer with a more efficient and reliable production solution to help them achieve greater success in the plastic recycling sector. We will continue to work closely with our customers to provide timely technical support and after-sales service to ensure that they can fully utilize plastic recycling machine’s potential.