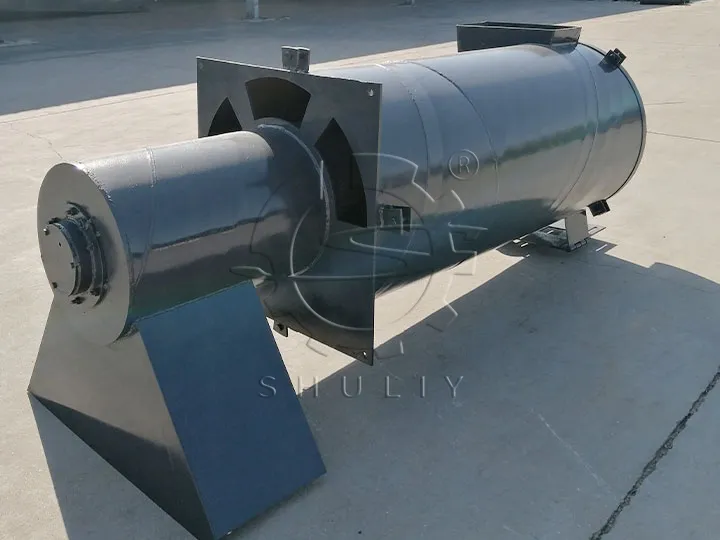

Shuliy plastic scrap dryer machines are state-of-the-art equipment designed to process waste plastics. It has a wide range of power from 7.5 kW to 15 kW and can be customized according to the customer’s needs. Whether it is plastic film, plastic bags, or other plastic products, this lifting dewatering machine can effectively handle them and hence is one of the indispensable equipment for plastic film recycling lines.

Plastic Dryer Advantages

- Plastic scrap dryer machines are typically constructed from stainless steel, which gives them good durability and corrosion resistance. This durability means that the equipment can run consistently for long periods, reducing maintenance costs and frequency.

- Plastic film dryer machines are designed to dry plastic film efficiently and quickly. Their specially designed heating and ventilation systems provide even heat distribution and adequate airflow to ensure fast and even removal of moisture from the plastic film. The plastic processed by the dryer may have residual moisture of only about 1-3%.

- Plastic drying machines can often be customized to meet specific customer needs. This means you can always contact Shuliy to develop a customized solution based on your production needs, space constraints, and budget. For example, you can choose from different-sized drying chambers, heating systems with different heating powers, and other customized options to meet your specific requirements.

Usage of Plastic Scrap Dryer Machine

During the recycling process of PP and PE plastic film, the cleaned plastic may become contaminated with moisture and other impurities. To ensure the quality and purity of the product, the vertical dryer utilizes heating and ventilation methods to effectively remove moisture and impurities, allowing the plastic fragments to regain favorable processing properties.

The plastic raw material treated by the dryer has better fluidity and stability, which is conducive to the subsequent granulation process, and can produce high-quality plastic granules for making a variety of plastic products, such as plastic packaging, tubes, injection molded products, and so on.

How Does a Lifting Dewatering Machine Work?

- The plastic film dryer mainly consists of a high-speed rotor and a removable screen.

- Utilizes the principle of high-speed centrifugal force and hot air circulation to achieve an efficient drying process.

- Firstly, the plastic film is placed on a high-speed rotating basket or screen inside the plastic scrap dryer machine to shake out the moisture in it by high-speed centrifugal force.

- The working speed of the equipment is 900-1500r/min. At the same time, hot air is introduced into the drying chamber, creating a circular flow that expels the moist air to maintain a dry environment. This design accelerates the evaporation and removal of moisture, thus realizing a fast and efficient plastic film drying process.

Specification of the Plastic Scrap Dryer Machine

- Application: Both rigid and soft PP PE plastic scraps.

- Material: High-quality imported stainless steel materials.

- Size: SL-500, SL-600

- Output Power: SL-500 has a power of 7.5KW and SL-600 has a power of 15KW.

- Propeller Blade Rotational Speed: 900-1500 revolutions per minute.

- Warranty: One-year warranty with no additional cost.

- Optional Pairing Devices: The plastic dryer is typically used in between the plastic washing and pelletizing processes, working alongside the cleaning tank and granulator. It can be purchased as a standalone unit or in combination with other equipment. We provide personalized guidance to help you choose the right purchasing option.

Plastic Film Dryer Machine Price

As an excellent manufacturer of plastic recycling machines, we offer a wide range of plastic scrap dryer machines at prices that vary by model, size, and features. Whether you need a plastic drying machine for small business or large industry, we have the right choice for you. Please feel free to contact us, we will provide you with detailed price information and product introduction according to your needs, to make sure you find the best plastic film dryer for you.

FAQ About Plastic Dehydrator

What types of plastic film is this plastic dryer suitable for?

The plastic film dryer is suitable for all types of plastic films, including polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), etc.

Do I need additional equipment to work with it?

In addition to the plastic scrap dryer machine, it is recommended to match the plastic washing machine, plastic crusher, and other equipment in the plastic film recycling line to realize the complete plastic recycling treatment process. You can always contact us for a personalized customized solution to increase your plastic recycling line rate.

Precautions for the maintenance of the plastic dehydrator?

Regularly clean the inside of the plastic drying machine and the ventilation system, keep the ventilation unobstructed, and timely replace the wearing parts, such as the heating tube, to ensure the normal operation and service life of the plastic film dryer machine.

Does Shuliy provide after-sales service and technical support?

We provide comprehensive after-sales service and technical support, including installation and commissioning, training of operators, equipment maintenance, etc., to ensure that customers have no worries about the use of the process.