Our heavy-duty rebar straightening machine takes your raw material—piles of bent, rusty, and otherwise unusable scrap rebar (from 6mm to 25mm in diameter)—and, in a single pass, transforms it into a valuable finished product: perfectly straight, clean, and profitable steel bars.

Whether you plan to sell these straight bars for immediate profit or use them as perfect raw material for your own bending and coiling machines, this is your starting point. This guide shows you how.

Why Choose Shuliy Rebar Straightening Machine?

We designed this rebar straightening machine based on feedback from hundreds of yard owners and fabricators. Here’s what makes it better, supported by real engineering facts:

Superior Straightness That Boosts Value.

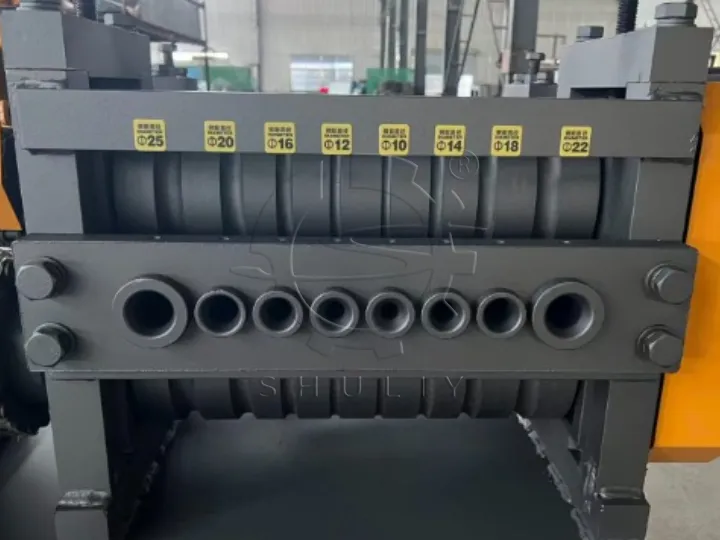

Our machine doesn’t just straighten; it perfects. The unique multi-roller system (5 or 6 holes) forces the rebar through 20 straightening cycles in a single pass. This intensive process guarantees a level of straightness that single-function machines can’t match, ensuring your finished product commands a higher price or performs flawlessly in subsequent fabrication.

Built Like a Tank for Non-Stop Profit.

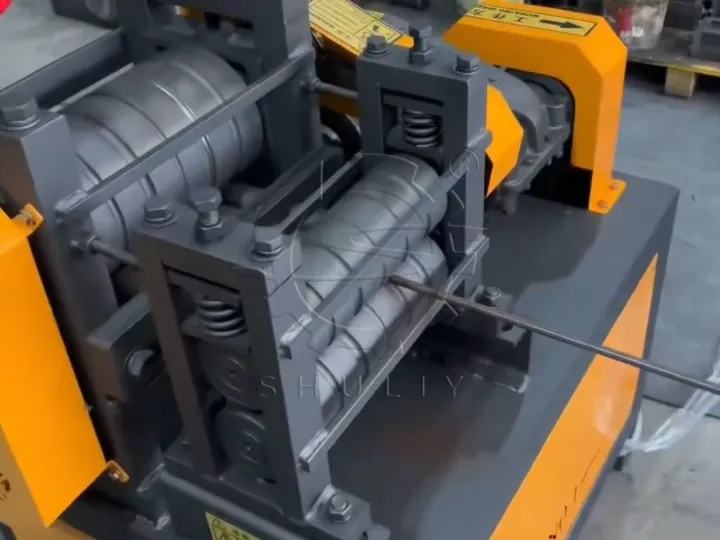

Downtime is lost money. That’s why our machine is built for continuous, heavy-duty operation. With a solid steel frame that gives it a substantial weight of up to 980kg (2160 lbs), it absorbs vibrations and stands firm. The critical straightening rollers are forged from hardened, wear-resistant alloy steel, ensuring they outlast standard components and keep your scrap rebar straightener running and earning, day in and day out.

Powerful, Efficient, and Saves on Energy.

Power without efficiency is just a high electric bill. We pair our machines with robust copper-core motors, ranging from a highly efficient 4kW for smaller diameters to a muscular 15kW for the 14-25mm model. This ensures you have exactly the power you need to process thick rebar without wasting energy, keeping your operational costs low.

So Simple, Anyone Can Run It.

You don’t need a highly skilled, expensive operator. The design is intuitive and safe. An operator simply feeds the bent bar into the inlet. The machine does the rest automatically. This simplicity means lower labor costs and faster operator training, directly impacting your bottom line.

How It Works: From Twisted Scrap to Straight Bar

The process is a perfect blend of power and precision:

- Feed: An operator takes a piece of your raw material—a bent steel bar—and guides it into the machine’s inlet.

- Straighten & Clean: The bar is pulled by powerful rollers into the high-speed straightening drum. Inside, the set of 20-cycle alloy rollers applies intense, multi-directional pressure, forcing the bar into a perfectly straight line. The friction from this process simultaneously scours away surface rust and concrete residue.

- Exit: A clean, straight, and uniform finished product emerges from the other side, ready for the next stage.

Who Is This Machine For? See If You Fit

This steel bar straightening machine for sale is a perfect fit for two main types of businesses. Which one are you?

Scenario 1: The “Scrap-to-Cash” Operator

- Your Business: You run a scrap metal yard, a demolition company, or you’re a raw material supplier.

- Your Goal: To maximize the value of the scrap steel you collect.

- How This Machine Helps: You’ll use this rebar straightening machine as a standalone workhorse. You feed in the piles of bent rebar you acquire cheaply and produce neat bundles of straight steel bars. You then sell these bundles directly to local construction companies, builders, or even smaller workshops for a substantial profit.

Scenario 2: The “Precision Fabricator”

- Your Business: You operate a workshop or factory that makes products from steel bars, such as concrete stirrups, steel rings, or custom-bent parts.

- Your Goal: To produce high-quality, accurate products efficiently and reduce material costs.

- How This Machine Helps: This machine becomes the crucial first step in your production line. You feed it low-cost scrap rebar to produce your own perfect raw material. This straight bar is then fed into your rebar bender or coiling machine, ensuring every final product is perfect and protecting your expensive fabrication equipment from damage.

Technical Specifications: Find Your Perfect Straightening Model

Choose the right model based on the rebar diameters you process. For a detailed rebar straightening machine price, contact our team for a transparent, all-inclusive quote.

| Model | Straightening Rod Diameter | Straightening Times | Straightening Length | Motor Power | Machine Weight | Machine Dimension |

|---|---|---|---|---|---|---|

| SL-6-10 | 6-10mm | 5 hole, 20 times/time | 500-2000mm | 4kW | 570kg | 1100*720*1150mm |

| SL-6-14 | 6-14mm | 5 hole, 20 times/time | 500-2000mm | 5kW | 730kg | 1200*780*1220mm |

| SL-8-16 | 8-16mm | 5 hole, 20 times/time | 500-2000mm | 5kW | 750kg | 1250*820*1300mm |

| SL-14-25 | 14-25mm | 6 hole, 20 times/time | 500-2000mm | 15kW | 980kg | 1550*890*1600mm |

Frequently Asked Questions (FAQ)

Can I make a profit just by selling the straight bars this machine produces?

Absolutely. This is a very common and profitable business model. There is a strong market demand for straight, recycled rebar. This rebar straightening machine allows you to buy low-cost scrap and sell a value-added product for a significant profit.

I have a bending machine from another brand. Will this straightener work with it?

Yes. Our straightener is a universal pre-processing machine. It is designed to provide standard straight bars that can be used as high-quality feedstock for any brand of bending, coiling, or cutting machine.

What if my business grows and I want to add more machines later?

That’s the beauty of this machine’s flexibility. You can start with just the straightener, and as your business expands, you can easily add a Shuliy rebar bending machine or coiling machine to create a fully integrated production line.

Why Choose Shuliy Machinery? Your Partner in Growth

- Flexible, Scalable Solutions: We offer equipment that can grow with your business, from a single profitable machine to a fully integrated production line.

- Global Support: Our expert team provides professional pre-sales consultation to help you choose the right solution for your current and future needs.

- A Commitment to Quality: We use only high-grade components because we believe reliable equipment is the foundation of any successful enterprise.

Whether you’re starting a new venture or upgrading an existing one, this machine is your key. Contact the Shuliy team today for a free, no-obligation quote on the versatile rebar straightening machine.