In recent days, the Paris Olympics in France is being held in full swing, and “recycled plastic” has become a highlight: local recycled plastic chairs, award podiums made from shampoo bottles and colored caps, and running tracks on the Olympic field, among other things. The utilization of these recycled plastics not only significantly reduces the hosting costs, is environmentally friendly and energy-saving, but also receives consistently positive reviews – recycled plastics have great development potential. Well, do you know how to recycle plastics efficiently and profit from it? This article will give an example of PET plastic recycling.

About PET Plastic Bottles

From the perspective of green environmental protection and economic sustainable development, recycled PET has extensive and significant practical value. In 2023, the PET plastic recycling rate in France was about 47%, and the goal of the French government and related institutions is to reach 90% by 2030.

Widely Application

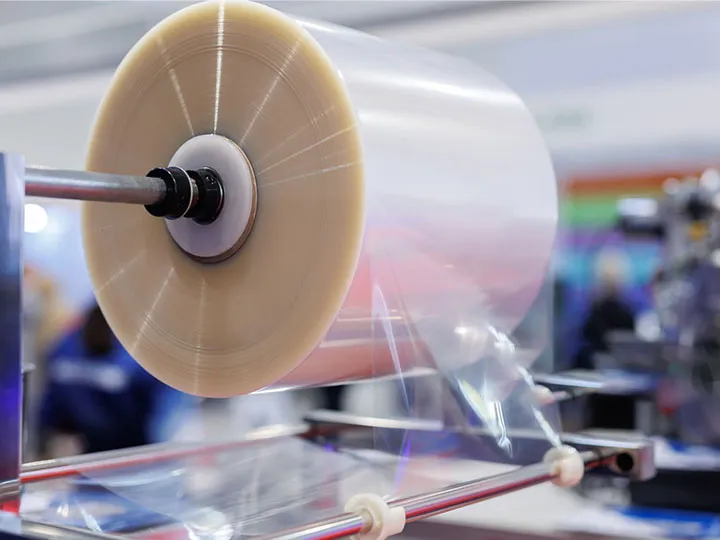

- Food field: beverage bottle: It has high transparency and good impact resistance, making it a common choice for manufacturing mineral water, fruit juice, and other beverage bottles.

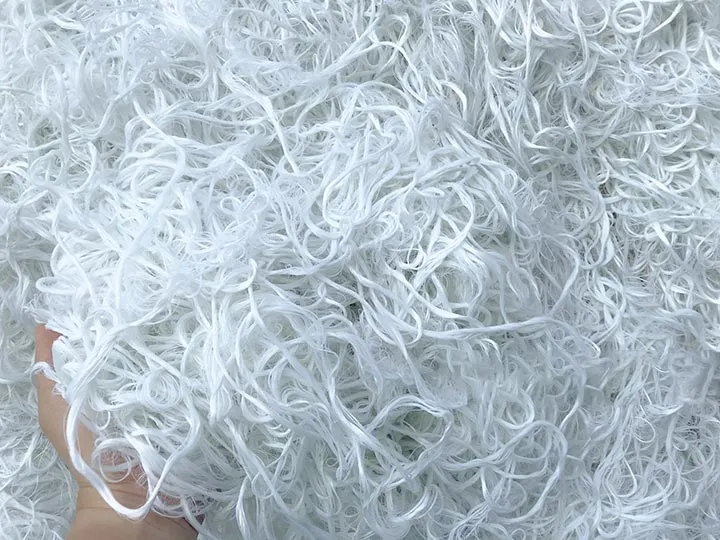

- Fiber products: PET can be spun as polyester fiber, and used to make clothing, carpets, etc., with good wear resistance and wrinkle resistance

- Electric field: It has excellent electrical insulation properties and can be used to manufacture insulating parts or cases for electronic equipment, such as mobile phones, and so on.

- Medical apparatus: Good chemical resistance and sterilizable properties make it suitable for use in making medical syringes, vials, etc.

Thriving Development Prospect

- Recycling and sustainable development: PET is one of the most easily recyclable plastics. Meanwhile, having the characteristic of low investment and high return makes PET recycling play a more and more essential role in the field of reusable resources.

- Modified PET: By adding different additives, PET plastic can be modified to have a wider range of applications, such as specialized packaging materials and 3D printing technology.

- Market requirement: Currently, the demand for PET is increasing, while the recycling rate is relatively low. As the focus on sustainability by governments, industries, and consumers is increasing across the world, the market demand for recycled PET will continue to grow.

Recommended PET recycling machine

As a professional PET plastic recycling machine supplier, Shuliy recycling machines have been successfully exported to many countries around the world, such as Kenya, Mozambique, and so on. We have the advantage of the following:

- High Capacity: The line is approximately 70 meters long and contains 19 machines, with a super strong plastic processing capacity, of up to 6000kg/h. Of course, it can also be adjusted according to the site and production needs, with a minimum plastic processing capacity of 500kg/h.

- Advanced technology: The production machines are meticulously crafted by a professional team, who carefully select materials for different parts of the machines and use automated systems, among other innovations, to continuously update and replace them to produce the most high-quality, durable plastic recycling machines.

- One-step service: We offer professional consulting services before the sale to help customers choose the most suitable purchase plan. During the sale, we can provide technical support, explain installation tutorials, and provide instructions on machine maintenance. Besides, we also offer a one-year warranty for after-sales service.

Introduction of PET Recycling Line

The video provides a comprehensive breakdown of the components comprising our PET plastic recycling line. If you’re interested, please feel free to contact us. You can also read the following websites: