Shuliy is an established plastic recycling machine company with decades of experience, offering a range of models of plastic recycling machines. This article primarily introduces how to select the best small plastic pelletizer machine for sale to achieve cost-effective and efficient plastic recycling.

Identify Needs Before Choosing a Mini Pelletizer

- Determine your production materials and their quantities.

- Measure your production site to estimate how many machines of a certain size can fit on it.

- Determine the production capacity you need.

Learn the Functions of the Various Parts of the Granulator

Learning more about the key parts of the small plastic pelletizer machine for sale in advance can help you select the most suitable machine. For example, Shuliy’s small plastic pelletizer machine for sale mainly consists of a heating device, a die head, a plastic pellet-cutting machine, etc. The specific functions are as follows:

Heating Device of The Pelletizer:

Melting plastic films into a liquid state through high-temperature heating. There are three common heating devices: electromagnetic heating, ceramic heating devices, and iron heating devices.

- Electromagnetic Heating: It is heated evenly by electromagnetic means, which is the most efficient and energy-saving method, suitable for customers who prioritize efficiency.

- Ceramic Heating Device: Heating is achieved through ceramic resistors, which offer even heating, and good stability, and are suitable for production environments where temperature distribution requirements are strict.

- Iron Heating Device: Steel drums are commonly used for small-scale granulation in production environments by heating them. The production cost-effectiveness is high, but temperature control requirements are not high for factories.

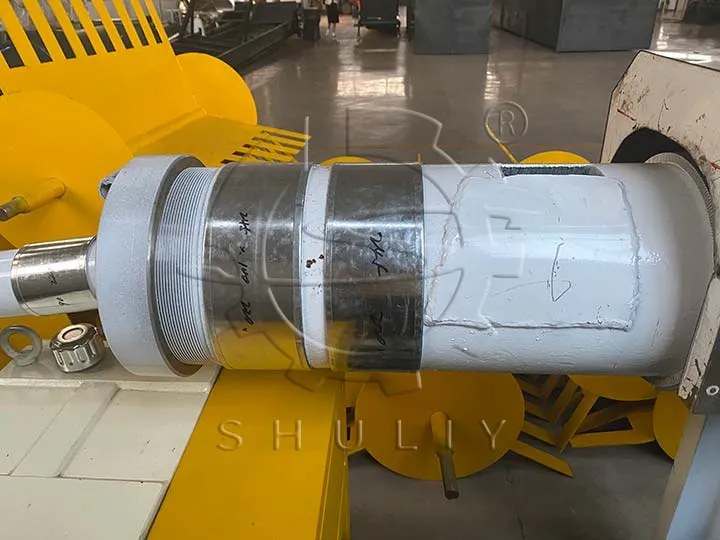

The Mold Head of the Plastic Pellet-Making Machine

Mold heads are specially designed to extrude plastic into dense ingots after melting for subsequent shaping and pelletizing.

- Hydraulic Die Head: The hydraulic filter head allows for easier filter changes, which can avoid frequent downtime due to filter changes.

- Automatic Filter: It is suitable for scenarios where continuous production is required and can automatically filter impurities in the plastic molten material.

- Electric Gear Die Head: It is suitable for production scenarios where precise control of the flow of plastic molten material is required, which can ensure consistency in the basic process and produce high-quality plastic granules.

Plastic Granules Cutting Machine:

Cutting plastics into uniform pellets.

- Water Ring Pelletizing: High efficiency, fast cooling, and cutting of plastic, suitable for customers with high production requirements.

- Strand Pelletizing: It is suitable for producing high-quality uniform particles, which can guarantee consistency in particle size and shape.

Read: Water Ring Pelletizer System for Efficient Plastic Recycling

Make a Sensible Combination

Choose the accessories that meet your production needs based on their production characteristics, such as continuous production, high-efficiency production, or energy saving. And you can mix and match them according to your budget, production environment, and so on. Shuliy can also provide suitable advice to help you select the purchase method.

Shuliy Small Plastic Pelletizer Machine for Sale

As a plastic recycling specialist, Shuliy provides various machines. If you’re interested, please feel free to contact us.