Guide to the Plastic Film Recycling

How to Recycle a Mixed Lot of Plastic Film Materials and Other Materials?

- Manual sorting: Before recycling, the materials are sorted by workers to separate different materials, to avoid affecting the physical properties of the final recycled products.

- Density separation: Different types of plastic materials have different densities, which can be separated by density in water. For example, PP and PE have a lower density and will float on the water surface, while PVC and PET have a higher density and will sink to the bottom of the water and can be discharged through a filtration system.

How to Deal With Raw Materials With Excessive Impurity Content in the Plastic Film Recycling Process?

- Multiple washing processes: You can increase the number of plastic washing tanks and repeat the washing process for the film several times.

- Utilize suitable agents: During the plastic recycling process, you can add an appropriate amount of cleaning agents, which can help to further wash PP PE films.

- Rinsing and filtering: If the film surface is heavily soiled, you can try adding a bleaching step. Soak the film in a solution of bleach dissolved in water for about half an hour, then rinse it clean and filter it. Be careful not to directly spray high-concentration bleach onto the surface of the film.

What Should Be Done When Equipment Wears Out Seriously During Recycling?

- Apply lubricating oil: By using lubricants, friction is reduced, wear is minimized, and heat is effectively transmitted between moving parts, helping to dissipate heat and prevent high temperatures from causing damage to parts.

- Use durable high-quality stainless steel materials: Shuliy plastic film recycling machines adopt high-quality stainless steel, which is durable and resists corrosion.

- Regular check: Regular inspections and maintenance, replacement of damaged parts, to prevent affecting production efficiency.

How Can We Deal With the Problem of High Moisture Content in the Film?

- Using efficient dryers: The process of plastic film recycling is achieved through the principles of high-speed centrifugal force and hot air circulation, resulting in efficient drying.

- Intelligent temperature control system: Pay attention to the temperature during the drying process to avoid deforming the plastic due to excessively high temperatures.

plastic drying machine and rinsing tank

The Quality of Recycled Plastic Granules is Unstable.

- Optimize the process parameters of the equipment: By adjusting temperature, pressure, screw speed, and other machine production parameters, you can control the production process and select the optimal process for your raw materials.

- Sort raw materials properly: Ensure that the quality of the plastic film entering the recycling line is consistent, reducing fluctuations caused by the mixing of materials from different sources.

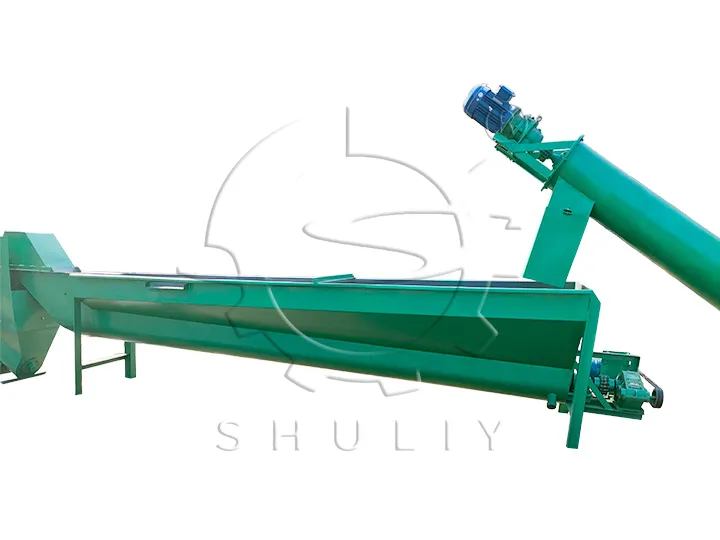

Shuliy Plastic Film Recycling Machine

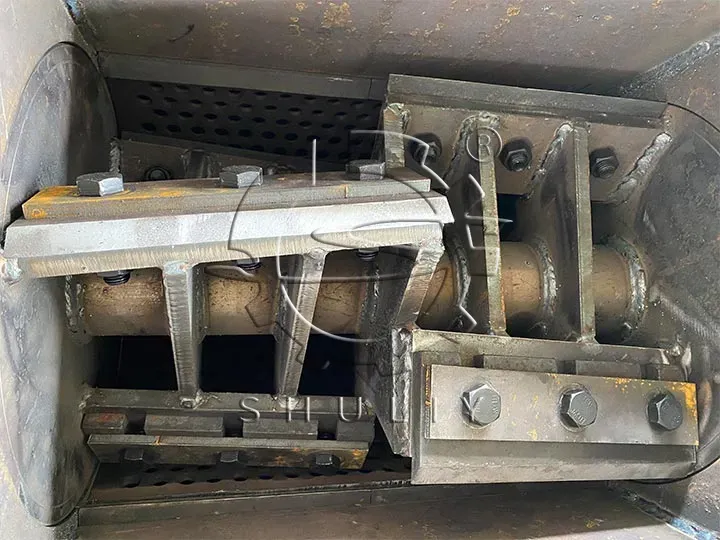

The Shuliy plastic film recycling line features high-quality, sustainable granulation, durability, high efficiency, and so on. Made of 60Si2Mn, the plastic crusher blades have a strong power to rapidly cut films into pieces and resist corrosion. What’s more, to avoid interruptions in granulation during filter changes, we can equip the system with an automatic filter and provide other customized plastic film recycling machines. If you’re interested, please feel free to contact us by clicking the link at the right bottom corner.