There are two types of styrofoam compactors: the vertical styrofoam compactor and the horizontal styrofoam compactor. To increase productivity and find the most suitable foam machine, it is important to understand the similarities and differences between them. The article explains these differences in detail.

What’s the Function of Plastic Foam Compactors?

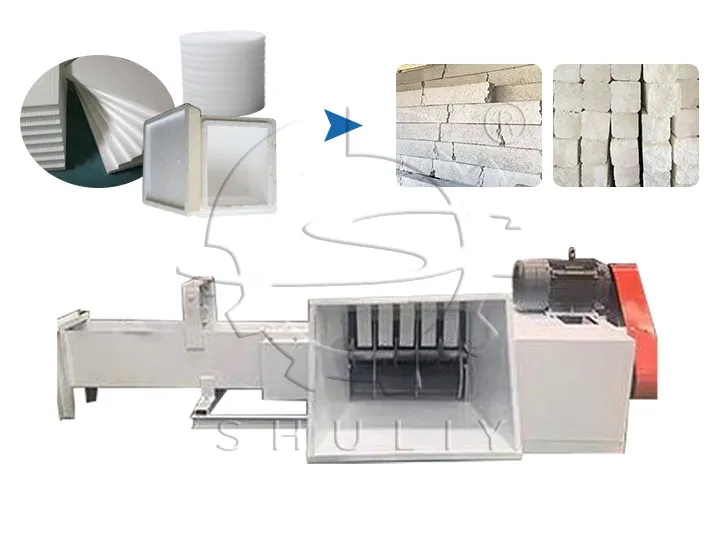

As a crucial component of the EPS EPE foam plastic recycling line, the plastic foam compactor is specially designed to compress large EPE or EPS plastics into dense ingots, which reduces foam volume up to 40:1. Their capacities range from 400~1000kg/h. To satisfy different production needs, verticle, and horizontal foam compactors are designed with different details, which are explained as follows.

The Difference Between Vertical and Horizontal Foam Compactors

Different Structure Design of the Two Machines

First of all, the structure designs are obviously different.

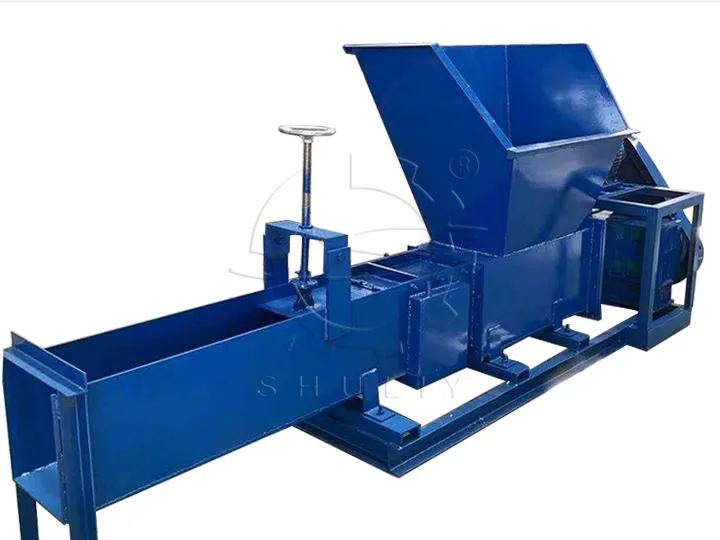

- The horizontal styrofoam compactor is placed horizontally and has a large footprint. Its feed inlet is usually at the side or front of the machine. And Foam is quickly discharged by horizontal compaction.

- The vertical foam compactor is designed vertically to use gravity to compress foam downwards. It has a small footprint. Foam is fed through the top inlet and discharged through the bottom outlet.

Different Applications Between Verticle and Horizontal Styrofoam Compactor

- Due to its smaller footprint, the vertical styrofoam compactor is more suitable for small-scale factories. It is also suitable for lines with smaller throughput requirements.

- The horizontal styrofoam compression machine is suitable for use in large-scale factories with a larger footprint and is capable of continuously handling large quantities of foam.

Different Capacity

- The vertical foam compactor has a relatively small capacity and is suitable for foam compaction processes with small volumes or small quantities.

- The horizontal foam compactor has a relatively high capacity and is suitable for handling larger volumes or large quantities of foam. The horizontal foam compactor is the best choice for factories with high demands on output and production efficiency.

How to Choose the Best Styrofoam Compactor?

In short, the verticle plastic foam compactor has a smaller footprint and smaller capacity, which is suitable for small-scale factories to recycle small volumes or quantities of plastic foam. While the horizontal styrofoam compactor has a larger footprint and capacity, which can be used in large-scale production.

Whether choosing a verticle or a horizontal styrofoam compactor, is based on your treatment demand, site conditions, and scale of production. If you have any questions, please feel free to consult us and we’ll provide the most sincere advice.