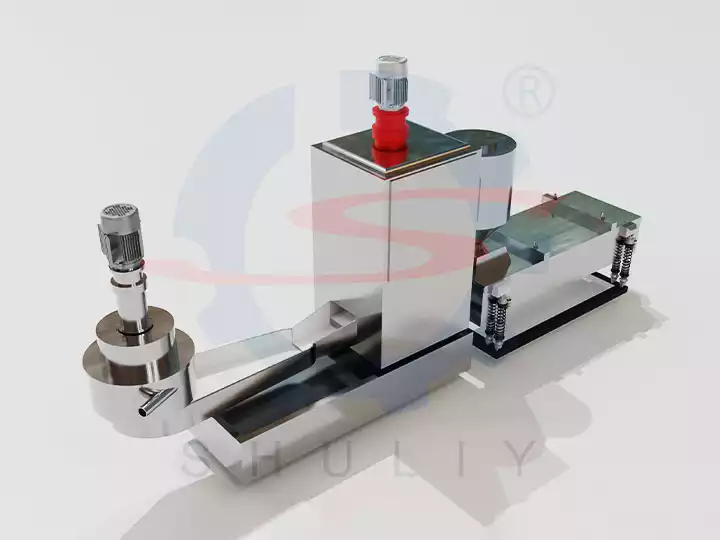

Introduction to Water Ring Pelletizer System Workflow

- After high-temperature heating and melting, dense plastic blocks are extruded from the die head.

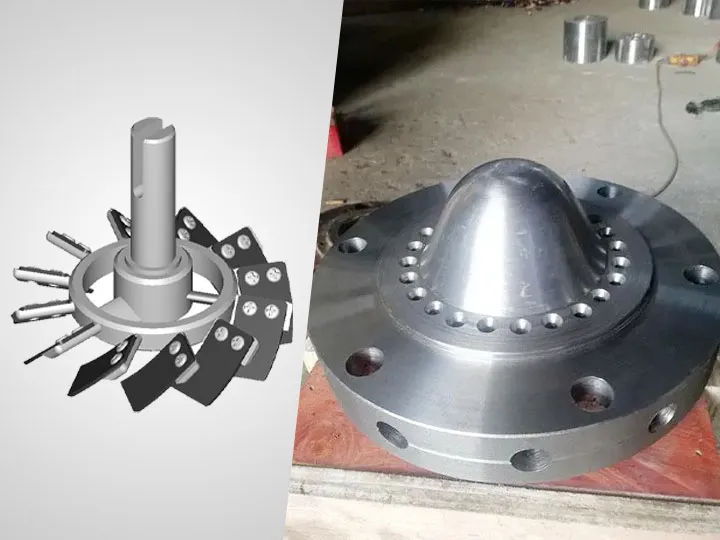

- The cutting head of the water ring pelletizer system rotates at high speed, forming a ring of water at the center, where the dense block is quickly cut into granules.

- The cooling effect of the water ring keeps the cutting head and the surface of the plastic pellets clean and lubricated, allowing for clear-cutting to occur simultaneously.

- After granulation, plastic pellets are dried in the horizontal drying machine.

The Advantages of Water Ring Pelletizing Machine

- Premium Plastic Pellets: The plastic pellets’ surface is even and smooth, with high density and good fluidity. It can also prevent the oxidation of the particles and reduce adhesion.

- Simple Operation: One-key startup, convenient to use, and easy to repair, which can reduce labor costs.

- Small Footprint: The pelletizing and cooling are carried out directly in the circular water belt. Without the need for a separate cooling tank, which can reduce the floor space and save space.

- Wide Application: Suitable for processing a variety of molten plastic materials, with high output, and able to meet the needs of large-scale production.

Application of Water Ring Pelletizer

The advanced water ring pelletizing technology can be used in the following applications:

- Recycle Waste Plastic: It can be used to recycle PE, PP, PS, and other plastic waste and transform them into recycled granules for further production.

- New Plastic Granulation: In the production of primary plastic, molten plastic is cut by a water ring pelletizer system for subsequent processing and production.

What is the Difference Between a Water Ring Pelletizer and a Strand Pelletizer?

- Different Manufacturing Process: After being melt-extruded, the water ring pelletizer system cut the material into granules immediately, while simultaneously cooling it. In the case of the strand pelletizing system, the material is first extruded from the die head and then stretched into a long strip, which is cooled in a cooling tank before being cut into granules.

- Different Pellets Shape: The granules of the water-ring pelletizer system are usually round or oval, with evenly shaped surfaces and better quality; the pellets made by strand pelletizer technology are mostly cylindrical.

- Different Application: The water ring pelletizer system is often used in large-scale production for high efficiency and particle requirements, while strand pelletizing technology is often used for pelletizing various high-viscosity materials, suitable for flexible handling of various materials.

Water Ring Pelletizer for Sale

Both the water ring pelletizer system and strand pelletizing machine have their advantages and contribute to pelletizing in plastic film recycling. Shuliy water ring pelletizing machine features high-quality, high-efficiency, and customizable. If you’re interested, please feel free to contact us.