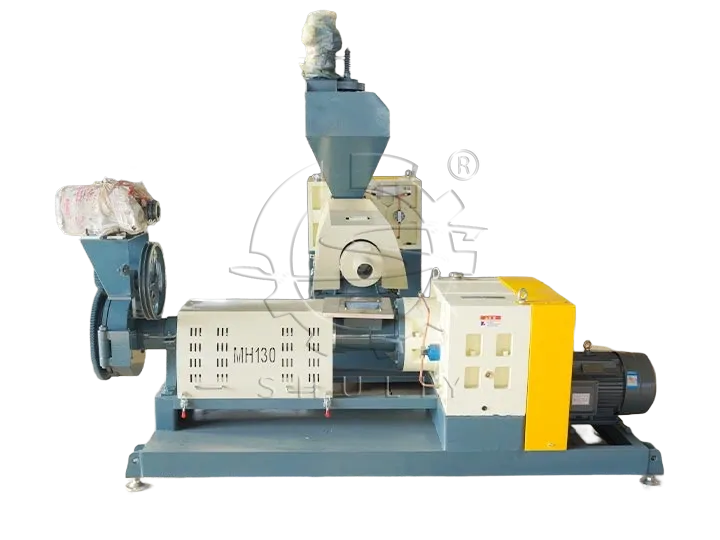

Recently, PE granulating machine from Shuliy was successfully shipped to South Sudan and put into operation in the customer’s factory. The waste plastic extrusion machine is mainly used to recycle and treat waste PE bottles and process them into recycled plastic granules for manufacturing various plastic products.

PE granulation line working process

The workflow of the PE granulating machine provided by Shuliy includes the following main steps: firstly, the waste PE bottles are crushed into small plastic fragments by plastic crusher, and then impurities and dirt are removed by plastic washing machine to ensure the purity of raw materials. Next, the cleaned fragments are dried, and the dried fragments enter into the plastic extruder, which are melted and evenly mixed under the effect of high-temperature heating and extrusion, and then extruded into plastic strips through the die is extruded and molded into plastic strips. Finally, the plastic strips are cut into small particles by the plastic pellet cutter, and then cooled and cured by the cooling tank to finally form the finished plastic pellets.

PE granulating machine working video

Waste plastic extrusion machine shipped to South Sudan

With the assistance of Shuliy’s engineers, PE granulating machines were successfully shipped to the customer’s plant in South Sudan and quickly put into operation. During the installation and commissioning process, Shuliy sent a technical team to provide on-site guidance to ensure the smooth operation of the equipment. The customer is very satisfied with the performance and productivity of the equipment.

Features of waste plastic granulator

After a period of installation and commissioning, the PE granulation line supplied by Shuliy has been successfully shipped to the customer’s plant in South Sudan and put into operation. The high efficiency and stable operation of this pelletizing line has been highly evaluated by the customer. In actual operation, Shuliy PE granulating machines show the following advantages:

- Efficient processing: It can process a large number of waste PE bottles every day, which greatly improves the recycling capacity of the plant.

- Product quality: the quality of the plastic granules produced is uniform and pure, which meets the customer’s demand for high-quality recycled materials.

- Easy operation: the whole pelletizing line adopts automatic control system, which is easy to operate, reduces manual intervention, improves production efficiency and effectively reduces production costs.