The Contribution of a Die Head to Plastic Granulation

The mold dead is mainly responsible for shaping and filtering the molten plastic, playing an important role in the plastic granulation process. Its specific functions include:

- Promote plastic shaping: The nozzle squeezes the molten plastic into long strips through specific perforated plates, and then cools and shapes them. The design of these perforated plates will affect the size and shape of the particles.

- Filter impurities: The filters in the die head will intercept impurities in the plastic melt, such as unmelted solid plastic fragments or other contaminants, to improve the quality and performance of the particles.

- Control the flow rate and pressure: The mold head can control the extrusion speed and pressure of the plastic melt, ensuring a continuous and even extrusion.

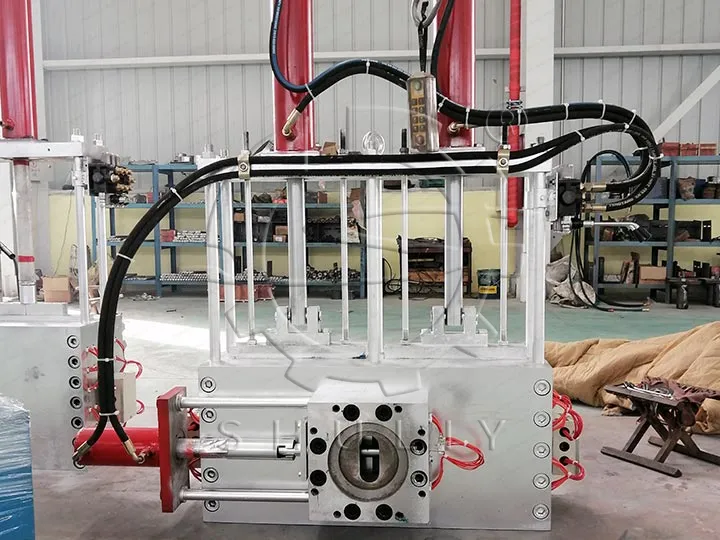

Hydraulic Die Head

Working principle

When the impurities in the molten plastic reach a certain level, the pressure rise triggers the hydraulic system to push the piston. Then the new filter is successfully replaced.

Features

There are two types of hydraulic die heads: Single hydraulic die heads and double hydraulic mold heads.

- The single die head: A short break is needed to change the filter. And it has a simple structure and is relatively easy to operate and maintain.

- The double die head: The system automatically switches filters without requiring downtime.

Application

- The single hydraulic mold head is suitable for small-scale production with fewer impurities during the production line process, with simple maintenance and lower cost.

- The dual hydraulic mold head can handle plastics with more impurities and is suitable for large-scale production lines with high requirements.

Automatic Filters

Working Principle

Combined with automated control systems, automatic filters automatically replace the filters when the pressure rises to a set value due to impurities blocking the filters.

Features

- The automation level is high and the impurity removal effect is good.

- Maintenance and operation can be somewhat challenging.

Application

- It is typically utilized to process dirty plastic materials.

- It can be used for mass continuous production.

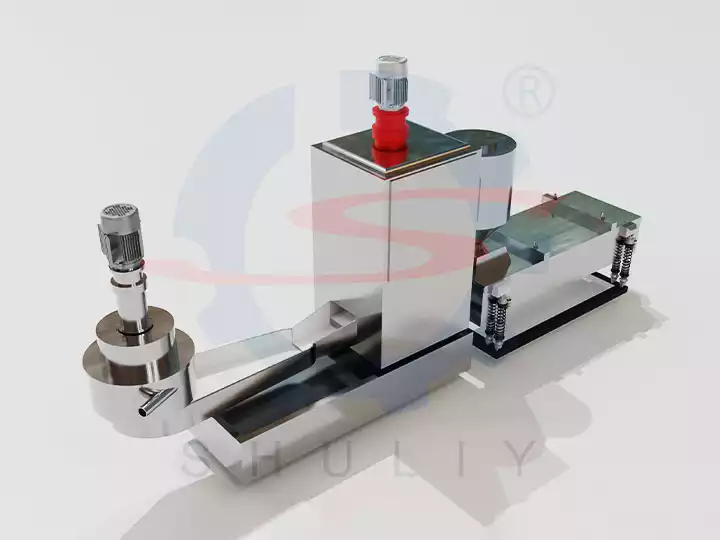

Electric Gear Die Head

Working Principle

An electric gear head uses an electric gear system to process plastic granules for production.

Features

- When switching the filter, you need to open the door.

- The electric gear mold head is simple structure, and easy to maintain.

Application

It is suitable for small to medium-sized production with less impurities.

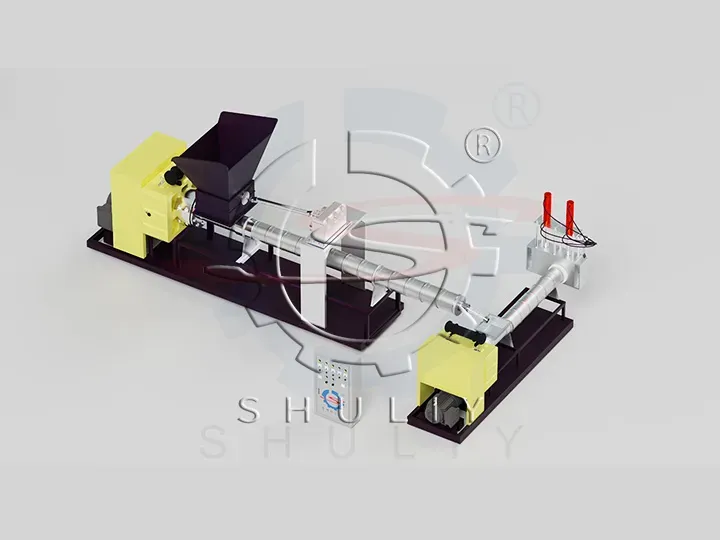

Various Shuliy Mold Heads for Sale

In conclusion, the hydraulic mold head is suitable for high-quality production environments with high impurity content and high cost; the automatic filter nozzle is suitable for large-scale continuous production of dirty materials; and the electric gear nozzle is easy to maintain and suitable for small-scale production lines with less impurities. All of them facilitate plastic pelletizing with high quality, high efficiency, etc.

We also provide other customized plastic recycling machines based on your production needs. If you’re interested, please feel free to contact us.