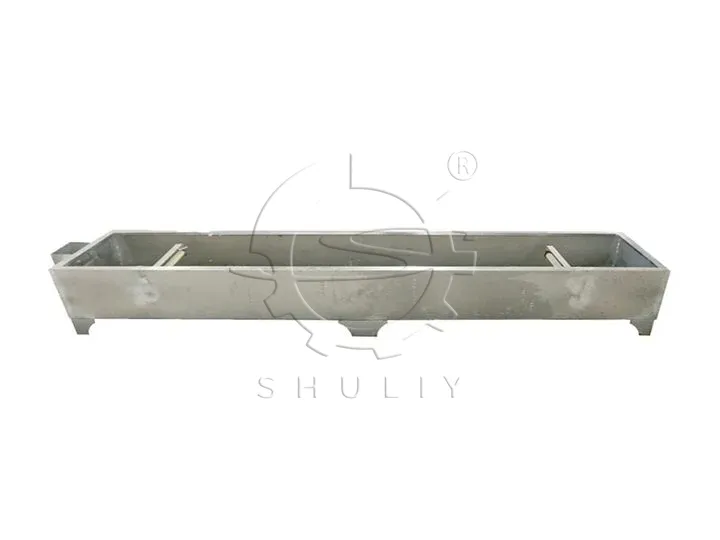

Shuliy cooling tank is usually 2.5m long and 0.4m wide, which can cool the plastic strip quickly and is one of the important pieces of equipment in the plastic pelletizing plant.

Cooling tank introduction

The plastic cooling machine is a vital piece of equipment in the plastic pelleting plant, and its role is to rapidly cool down the plastic strips extruded from the plastic pelletizer. Once the plastic has been processed through the extruder to form the strip, it is still at a high temperature and needs to be cooled quickly to maintain its shape stability and mechanical properties.

The water cooling plastic recycling machine effectively reduces the temperature of the plastic by utilizing the circulating flow of cooling water by immersing the hot plastic strip in the cooling machine for plastic, preventing it from deforming or losing its desired shape and properties during subsequent processing. This rapid cooling helps to maintain the quality and consistency of the plastic pellets, ensuring that the quality of the final product meets the desired standards while improving productivity and process stability.

Features of plastic cooling machine

- The cooling tank is made of corrosion-resistant and high-temperature-resistant high-quality materials to ensure long-term stable operation and efficient cooling.

- The reasonably designed cooling structure ensures that the plastic strips are cooled evenly during the cooling process, avoiding quality problems caused by excessive temperature gradients. And

- The water cooling plastic recycling machine can rapidly cool down the hot plastic strips, which greatly shortens the production cycle.

- By precisely controlling the temperature and flow rate of the cooling water, the cooling tank ensures the temperature uniformity and stability of the plastic granules, thus guaranteeing the quality of the product.

The role of cooling machine in plastic pelletizing line

The cooling tank is an integral part of a complete plastic pelletizing line. It is located after the plastic extruder and is responsible for handling the hot plastic strips extruded from the extruder. Its role is not limited to cooling but also includes the cooling and shaping of the plastic strip, surface cleaning and other processes. By controlling the temperature and flow rate of the cooling medium, the plastic cooling machine ensures that the plastic strip reaches the desired temperature in a short period of time and maintains its shape and quality. This provides a reliable prerequisite for the subsequent cutting and packaging processes and ensures the continuity and stability of the entire production line.