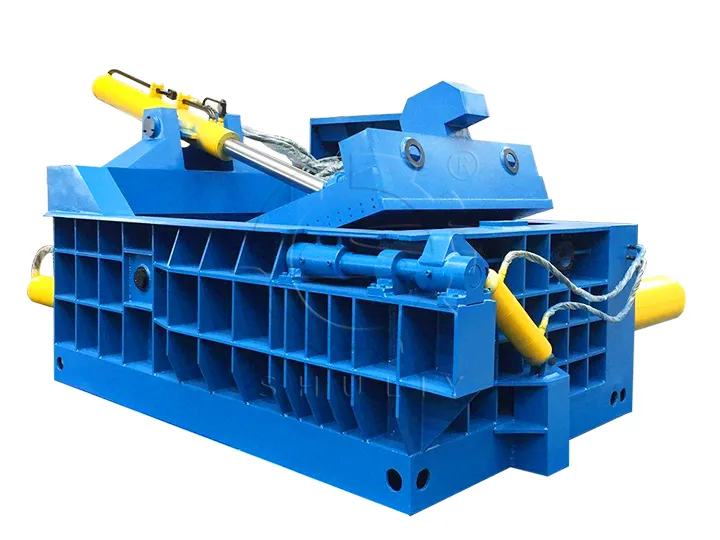

Um die Speichereffizienz und die Schmelznutzungsraten für Schrottmetall zu verbessern, hat Shuliy Machinery mehrere Modelle von hydraulischen Schrottmetallpressen entwickelt. Diese Pressmaschinen sind dafür ausgelegt, loses Metall in regelmäßige Formen zu komprimieren, die für Öfen geeignet sind. Sie unterstützen verschiedene Entladeverfahren und können je nach Kundenbedarf für unterschiedliche Verarbeitungskapazitäten angepasst werden. Unsere hydraulischen Schrottmetallpressen werden in der Recyclingverarbeitung, Metallurgie, Gießereien und anderen Industrien weit verbreitet eingesetzt.

Breite Palette & Produkte des hydraulischen Schrottmetallpressers

Eine hydraulische Presse kann verwendet werden, um Stahl- und Eisenspäne, Aluminiumdosen, Kupferdraht, Autoschalen, Ölfässer und andere eisenhaltige und nichteisenhaltige Metalle zu komprimieren. Sie ist ein wichtiges Werkzeug für das Recycling von Metallen in den folgenden Branchen:

- Schrottrecyclingstationen

- Metallurgische und Gießereibetriebe

- Schrottfahrzeugdemontageanlagen

- Verarbeitungsanlagen für Kupfer, Aluminium und Edelstahl

Angetrieben durch hydraulischen Druck werden Schrottmetalle zu hochdichten Ballen in quadratischen, zylindrischen oder achteckigen Formen gepresst. Die Ballenmaße liegen typischerweise zwischen 300*300 mm und 600*600 mm und können je nach Art und Größe des Rohmaterials angepasst werden, um verschiedenen Schmelzanforderungen gerecht zu werden.

Vorteile unserer Schrottbalkenpressmaschine

- Vollhydraulischer Antrieb – Gewährleistet eine stabile, leistungsstarke und sichere Verdichtung von Schrottmetall.

- Mehrere Steuerungsmodi – Manuelle Bedienung oder PLC-Automatiksteuerung verfügbar.

- Flexible Entladeoptionen – Seitenpress-, Frontpress- und Ballenumschlagtypen, um verschiedenen Materialarten und Standortlayouts gerecht zu werden.

- Keine Fundament erforderlich – Einfache Installation ohne Ankerbolzen.

- Dieselmotor optional – Geeignet für den Einsatz im Freien oder in Gebieten ohne stabile Stromversorgung.

- Breite Palette von Modellen – Verdichtungsdruck von 125 T bis 400 T, Ballengrößen von 300×300 mm bis 600×600 mm.

- Anpassbare Ballenformen – Quadratische, zylindrische oder achteckige Blöcke, um unterschiedlichen Schmelzbedürfnissen gerecht zu werden.

- Kompaktes und langlebiges Design – CNC-bearbeitete Teile gewährleisten eine lange Lebensdauer und einfache Wartung.

- Energieeffizient – Der Motor stoppt automatisch nach dem Pressen, um Strom zu sparen.

- Vielseitige Anwendung – Geeignet für eisenhaltige und nichteisenhaltige Metalle sowie für leichte Schrottteile wie Aluminiumdosen oder Kupferdraht.

Parameter der hydraulischen Schrottbalkenpressmaschinen

| Modell | Y81- 125 | Y81- 135 | Y81- 160 | Y81- 200 | Y81- 250 | Y81- 315 | Y81- 400 |

| Hydraulischer Druck | 125 T | 135 T | 160 T | 200 T | 250 T | 315 T | 400 T |

| Ballengröße | 30*30 cm | 30*30 cm | 35*35/40*40 cm | 45*45 cm | 50*50 cm | 50*50/60*60 cm | 60*60 cm |

| Ballengewicht | 30-50 kg | 30-50 kg | 50-180 kg | 100-200 kg | 200-800 kg | 700-1500 kg | 1000-1500 kg |

| Zykluszeit | 100 s | 110 s | 110-130 s | 140 s | 150-160 s | 170-200 s | 180 s |

| Motorleistung | 15 kW | 18,5 kW | 18,5 / 22 kW | 22 kW | 44 kW | 60 kW | 90 kW |

| Silo Volumen | 300 L | 300 L | 300/600 L | 600 L | 800-1000 L | 1000-1500 L | 1500 L |

Wie funktioniert die Metallballemaschine?

Der hydraulische Schrottpressen besteht hauptsächlich aus einer Verdichtungs kammer, einem hydraulischen System, einem elektrischen Steuerungssystem, einer Energieeinheit, einem Entlade mechanismus und einem Sicherheitsgerät. Der Pressvorgang kann in die folgenden Schritte unterteilt werden:

- Rohmaterialzufuhr (manuell oder Förderband).

- Hydraulikzylinder mit mehrstufiger Kompressionsformung

- Formung zu Ballen

- Wählen Sie eine Entlademethode, um die Briketts herauszudrücken.

Hydraulische Schrottballenpresse Preis

Unsere hydraulischen Schrottpressen bieten hervorragende Leistung zu wettbewerbsfähigen Preisen. Die Kosten für eine Schrottpresse variieren je nach Modell, Kapazität und Konfiguration. Wir bieten vollständig anpassbare Lösungen, die auf Ihre spezifischen Recyclingbedürfnisse zugeschnitten sind.

Kontaktieren Sie uns noch heute, um ein persönliches Angebot zu erhalten und Ihren Metallrückgewinnungsprozess zu optimieren!