Project Overview

Last year, we received an inquiry from Sri Lanka, from a client interested in plastic pelletizing machines. Through our discussion, we learned that he was well-informed about the plastic recycling market in Sri Lanka but was hindered by the limited local plastic recycling infrastructure. Our sales manager showcased the client images and videos of the plastic granulator produced by Shuliy Factory, and the customer readily expressed his willingness to cooperate.

Thanks to the trust of this customer. After comparing multiple models, he finally decided to purchase an SL-800 pelletizer for PP, PE, PVC, etc., whose output can reach 350kg/h.

Why Does this Client in Sri Lanka Choose Shuliy?

- Market demand: There are not enough plastic recycling facilities in Sri Lanka, and many plastic recycling factories face the problem of high costs. However, our Shuli plastic recycling machine can save energy and reduce production costs.

- High-efficiency: In addition to the SL-180, we also provide various recycling machines to satisfy different production needs, which can reach up to 410kg/h.

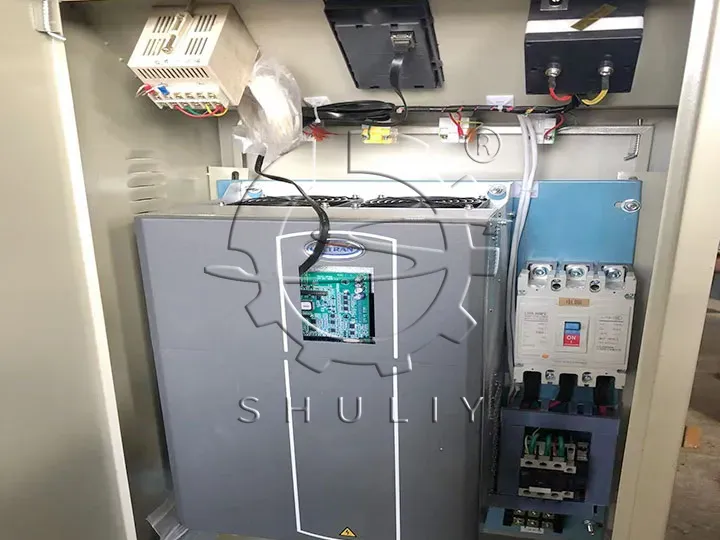

- Highly technical: Utilizing advanced screw melting technology, various parts options available, etc. make plastic pellets high-quality enough to satisfy recycling requirements. For example, we offer two cutting methods (water ring and strand pelletizing), three heating methods (electromagnetic, ceramic, and iron plate), and three mold heads (hydraulic, electric gear, and automatic slag remover) to efficiently produce high-quality plastic granules for recycling.

- High-quality: Made of high-quality stainless steel, our machines are highly corrosion-resistant and can be used for a long time.

- Customizable: The granulator consists of various parts and each of them can be customized to satisfy customers’ needs. If needed, you can consult us and we can provide detailed assistance to help you choose the most suitable purchase method.

- Excellent service: Before sales, we have professional staff available to provide timely responses, answer inquiries regarding machine details, and design exclusive solutions tailored to your specific needs. During sales, we can provide technical assistance, installation guides, and demo videos. After-sales, we offer a one-year warranty with no extra costs.

Plastic Pelletizer Parameters:

| Model | SL-180 |

| Screw diameter | 180mm |

| Spindle speed | 40-50/min |

| Main motor power | 55KW |

| Reducer hard gear | 280 |

| Weight | 2.2t |

| Size | 3.2*0.7*0.8m |

| Output | 350kg/h |

The plastic pelletizing machine is specially designed for transforming plastic flakes into high-quality uniform pellets, which can be used in plastic reproduction. The processes consist of melting, cooling, and cutting, which can achieve efficient granulation for PP, PE, PVC, HDPE, etc. Through granulation, the waste plastic can be converted into different sizes of granules for different production processes. Besides, we can also add various additives during the granulation process to modify the plastic to improve plastic usability.

Related

If you’re interested and want to learn more, please feel free to contact us. You can also view this website: