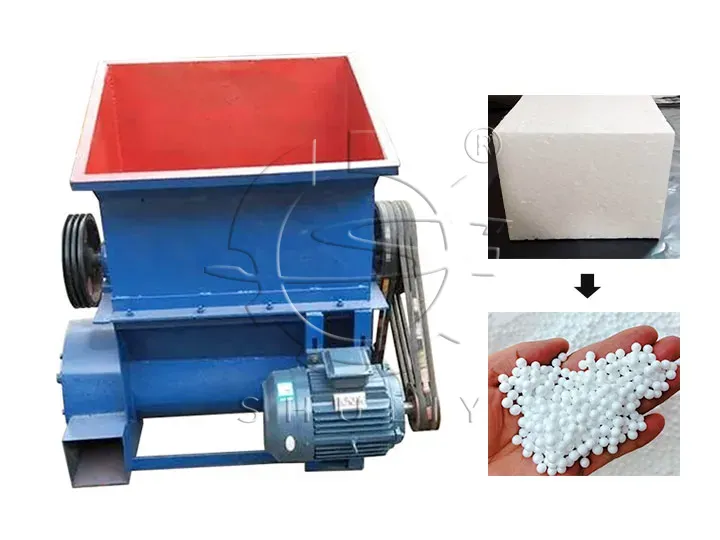

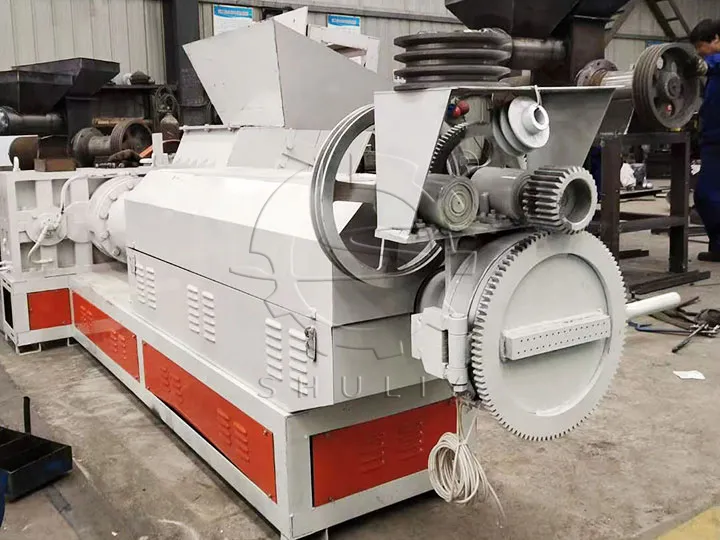

Shuly EPE recycling machine is an essential tool in the EPE foam recycling and reuse field, converting waste EPE foam into reusable granules. It has a capacity of 150~200kg/h and can be customized to meet all sizes of factories’ needs.

- Capacity: 150~200g/h

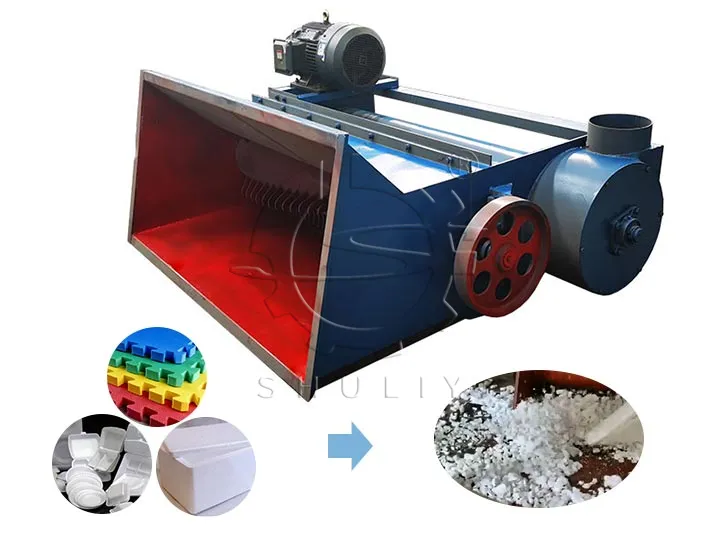

- Raw Materials: EPE styrofoam

- Final Products: High-quality granules

- Application: EPE foam recycling line

Key Highlights of EPE Recycling Machine

What’s the Raw Material and Final Product of the EPE Foam Extruder?

Raw Materials

Expanded Polyethylene(EPE) is a non-crosslinked closed cell structure, also known as pearl cotton, formed by low-density polyethylene(LDPE) foam to produce numerous independent bubbles, with waterproof, shock-proof, strong plasticity and other characteristics. Its application covers various fields, for example:

- Electronic appliances;

- Packaging medical equipment;

- Interior decoration in vehicles and rooms;

- Lighting fixtures, and other delicate high-end products as well as daily necessities;

- Indispensable sunshade supplies for chemical cold storage facilities and camping gear.

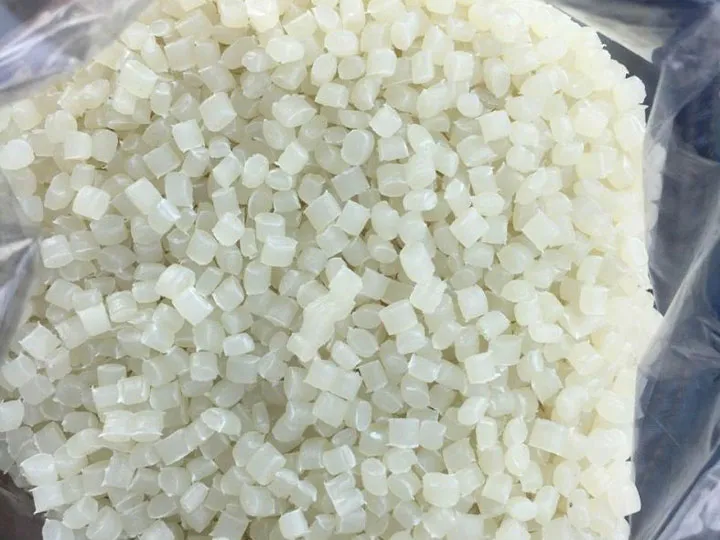

Final Products

The Shuliy EPE recycling machine converts these EPE foam plastics into high-quality usable granules at a speed of 150~200kg/h. If you’re a foam recycler or a producer, welcome to inquire. The final products produced by our foam extruder are uniform and high-quality enough to satisfy all sizes of factories’ needs.

What’s the specification of the EPE Foam Recycling Machine?

| Model | SL-160 EPE recycling machine |

|---|---|

| Dimensions | 3400mm x 2100mm x 1600mm |

| Feed Inlet Size | 780mm x 780mm |

| Power | 30 kW |

| Production Capacity | 150-200 kg/hour |

| Heating Method | Heating Coil |

SL-160 plastic foam granulator is one of the best-selling models of Shuliy. It adopts advanced screw melting technology Besides, we also provide several models of foam granulators to meet your various granulation needs. For further information or inquiry, please feel free to contact us.

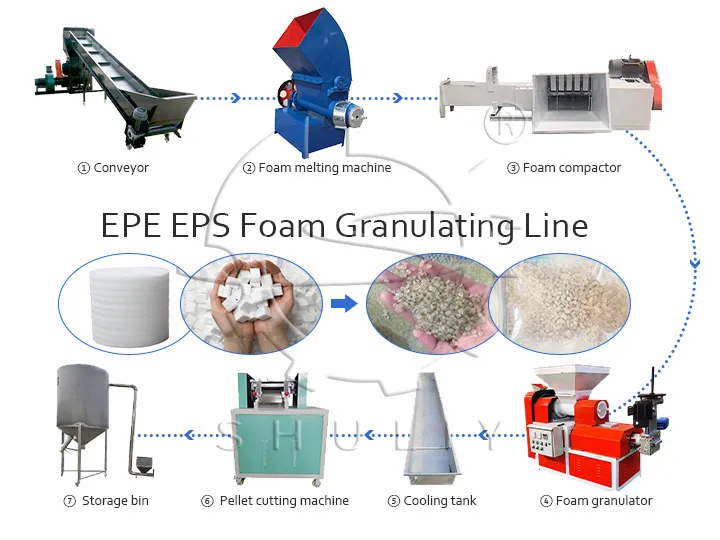

How Does an EPE Plastic Foam Pelletizing Work?

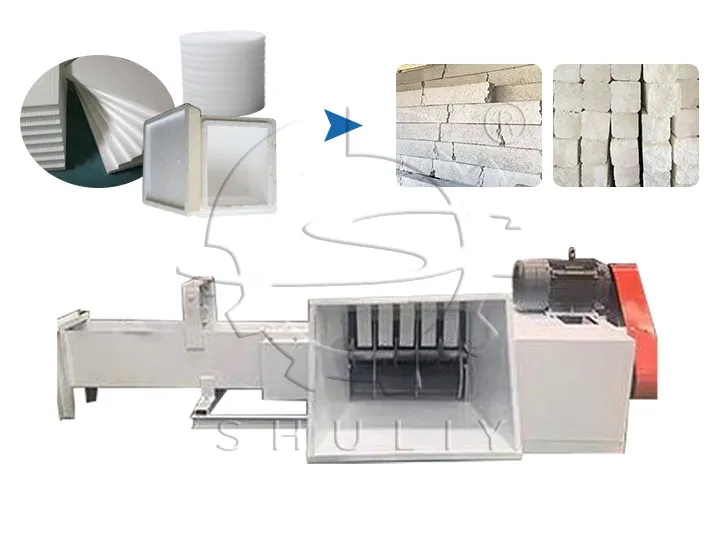

Strand Pelletizing System

EPE recycling machine is a kind of equipment commonly used in the reproduction of EPE foaming, containing the process of screw melting, compressing, cooling, and cutting.

- Firstly, the raw plastic foams are put into the hopper of the EPE foam granule machine;

- Then the raw materials are heated up to a certain temperature by the heating unit to reach a molten state suitable for extrusion.

- Subsequently, the heated plastic passes through the screw extruding mechanism and is extruded into dense blokes in the shape of a continuous plastic strip.

- Throughout the process, precise adjustment of parameters such as temperature control, extrusion pressure, and speed is critical to ensure the quality and performance of the final product.

Water-ring Pelletizing Unit

The water-ring system mainly contains a die mold, granulation system, heater, pump, frequency converter, and circulating cooling pool.

- First, the plastic is squeezed into long strips by the die head.

- Unlike ordinary granulation, the long strips of plastic are not cooled immediately, they are directly cut into pellets by a rotating circular cutting machine, and then thrown into a spiral flow of water for preliminary quenching.

- Finally, the pellets are passed through temperature-controlled water from the granulating chamber and into the centrifugal dryer. In the dryer, the water is drained back into the cooling pool, cooled, and recycled, while the grain is removed by centrifugal dryer.

What does Shuliy Do for You about Shipment?

So, if you’re interested in our EPE recycling machine, please feel free to contact us. Besides, here is a customer’s feedback video showing how it works.

Shuliy Plastic Foam Granulator for Sale

Are you curious about the price of the Shuliy EPE recycling machine? With advanced design and easy operation, our plastic foam extruders are capable of achieving precise granulation results, ensuring the efficient and stable operation of your plastic foam recycling line. If you are interested in our plastic foam granulator, please feel free to contact us, we will be happy to provide you with detailed information and the most favorable price!