Project Overview

We have received a consultation from a customer in Malaysia regarding the SL-400 plastic EPS compactor. After talking, we learned that the customer has his plastic recycling plant and he is looking to purchase additional machines. After the consultation, he decided to place an order with Shuliy due to his trust in our factory and the excellent service we provide. During the consultation, we sent the client pictures and videos of the machine, and the experienced manufacturer client was satisfied immediately. After we sent the best price and promised a quick delivery before the holiday, he paid the deposit promptly.

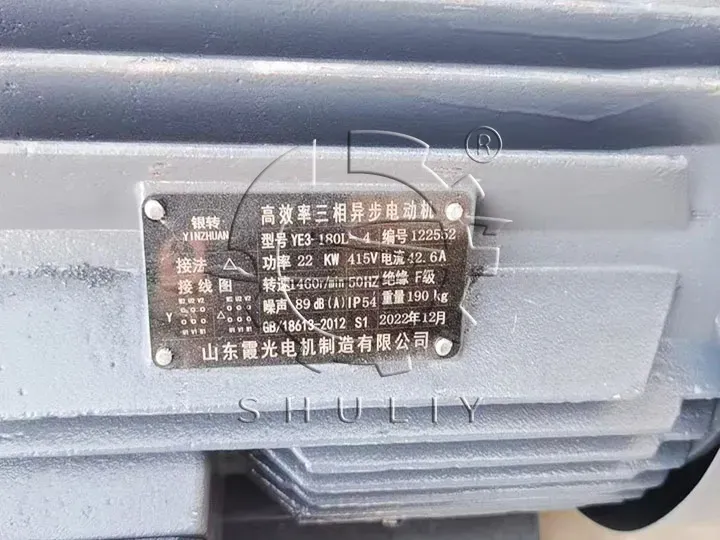

In the following conversation about the machine size, the customer expressed that their products do not need a fast compressing speed. They requested to change the motor pulley diameter from the standard 7 inches to 5 inches and adjust the gearbox pulley from 280mm to 240mm. We fulfilled the customer’s requirements by supplying a customized machine and double-checking the machine size to prevent any errors. Our meticulous work ethic and prompt delivery have garnered praise from our customers. We appreciate the trust of our Malaysian client and are pleased to have completed the delivery with our extensive industry experience. Both parties have reached a satisfactory level of cooperation.

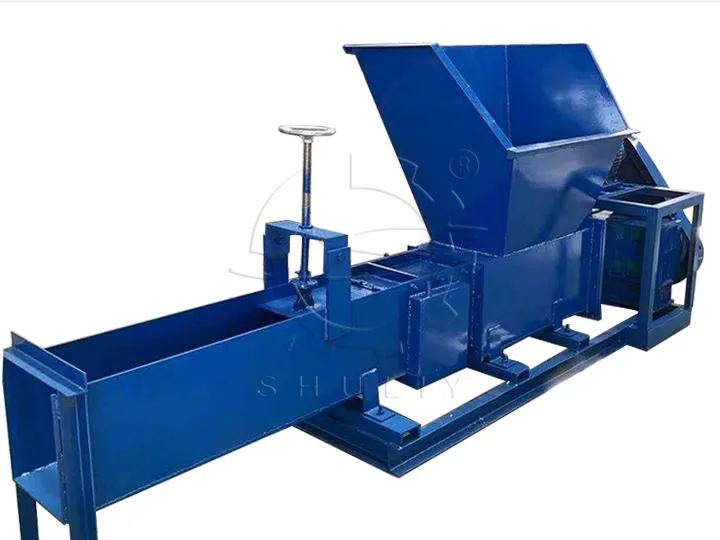

Details of the Malaysia Plastic Foam Cold Compactor

| Model | SL-400 |

| Machine Size | 3200*1600*1600mm |

| Input Size | 870*860mm |

| Power | 2.2KW |

| Capacity | 300kg/h |

| Voltage | 415v 50hz 3p |

| Service | One-year warranty, technical assistance |

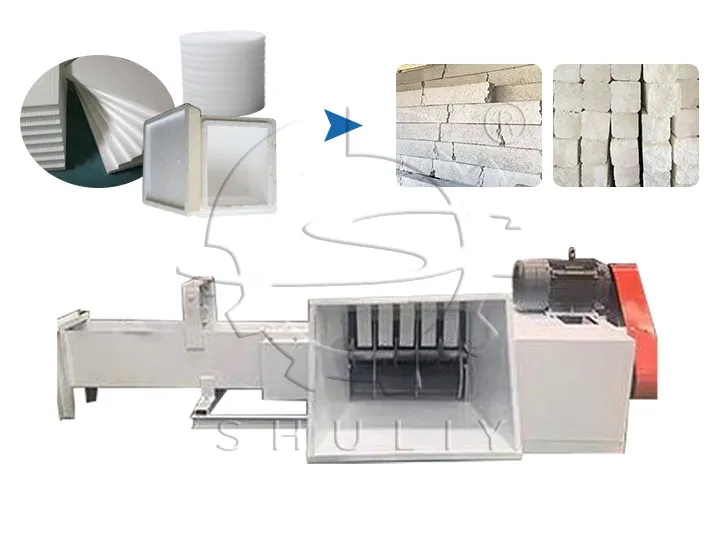

Our styrofoam compactor is specially designed for compressing large plastic foams into small dense sheets or ingots, making subsequent recycling processes of melting and pelletizing easier. Unlike conventional compression methods, cold pressing is beneficial for preserving the integrity of foam plastic and avoiding unnecessary degradation caused by heat. Under the action of a cold pressing machine, the foam volume ratio can be rapidly reduced to 40:1, greatly facilitating its storage, transportation, and other recycling processes.

Why Shuliy Styrofoam Compactor

- Excellent Service:

- Pre-sale: We provide detailed consulting services before the sale, introduce our plastic recycling machines, and provide practical purchase solutions based on our customer’s production needs.

- On-sale: Ensure fast international logistics, provide technical assistance, and explain installation tutorials.

- After-sale: There is a one-year warranty, and our engineers can also provide on-site installation if needed.

- High-efficiency: Our styrofoam compactor can be used for continuous operation and can efficiently compress foams into 40:1. Besides, the products have a characteristic of dense and complete physical properties.

- Energy Conservation: The machine performs cold pressing operations at room temperature without heating, saving energy consumption.

- User-friendly: The automatic system allows the vast majority of workers to use it easily. And the compactor is easy to disassemble and clean.

Operation Images

More Information About EPS Compactor

For more information about our styrofoam compressor, you can view the following website: