¿Cómo se pueden reciclar y reutilizar eficientemente los neumáticos OTR? Las líneas de reciclaje de neumáticos OTR de Shuliy están diseñadas para convertir neumáticos de 1400 mm o más en polvo de caucho. Este polvo se puede utilizar en asfalto y productos de caucho reciclado, proporcionando beneficios económicos y medioambientales.

Materias Primas y Productos Terminados

Las materias primas básicas para la línea de reciclaje de neumáticos OTR son neumáticos OTR desechados, como neumáticos de minería, neumáticos de movimiento de tierras, etc. Estos neumáticos gigantes tienen un gran volumen y están compuestos de caucho, alambre de acero, negro de carbón, fibras de nailon, etc. La línea de reciclaje de neumáticos OTR tiene como objetivo descomponer estos neumáticos y procesarlos en materias primas reutilizables, que incluyen:

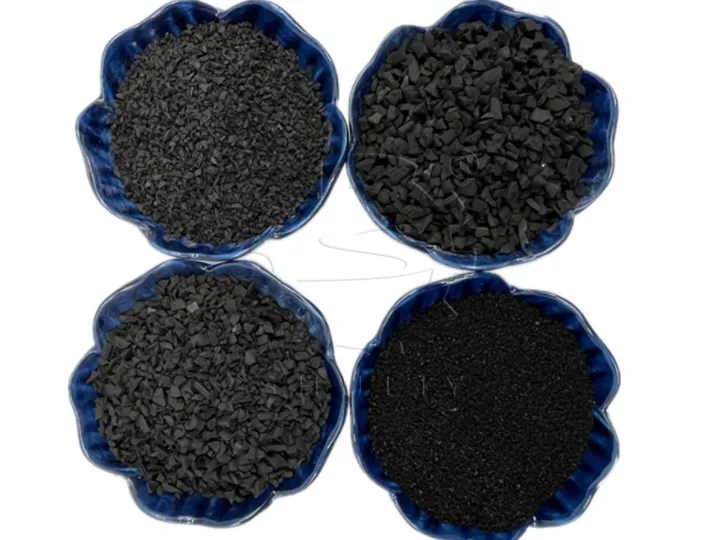

- Polvo de caucho: con finura ajustable en el rango de 10–40 mallas y una pureza de hasta el 99%, que se puede utilizar como materia prima para varios tipos de productos de caucho reciclado.

- Los alambres de acero se pueden vender directamente a las plantas de acero.

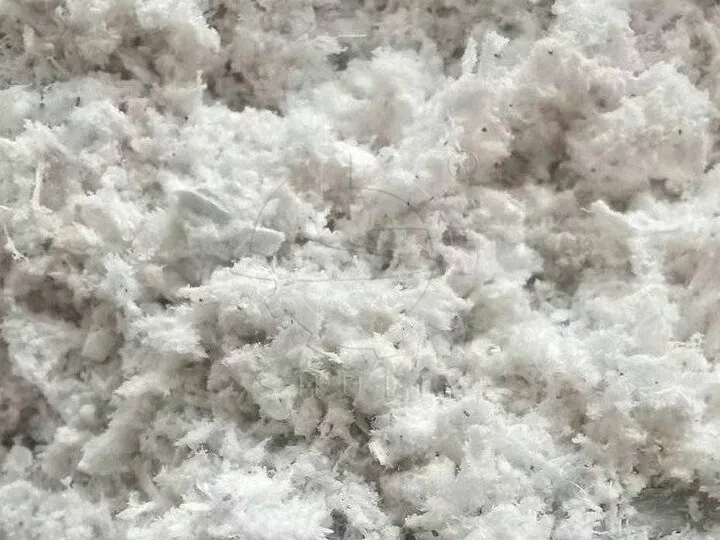

- Las fibras se pueden utilizar como combustibles alternativos.

¿Por qué la línea de reciclaje de neumáticos OTR de Shuliy lidera el mercado?

- Este sistema está especialmente diseñado para una variedad de neumáticos grandes fuera de carretera (OTR).

- Asegura un funcionamiento robusto, continuo y eficiente durante largos períodos sin atascos ni averías.

- Produce productos terminados flexibles y ajustables que son de alta calidad, valiosos y rentables.

- El sistema es completamente automatizado, ahorra mano de obra y es fácil de operar.

- Además, es eficiente en el uso de energía y respetuoso con el medio ambiente.

Dos líneas de producción de reciclaje de neumáticos desechados disponibles

Línea de Reciclaje de Neumáticos OTR 1:

Proceso de operación: máquina despojadora de neumáticos OTR → máquina cortadora de neumáticos OTR → trituradora de neumáticos → molino de neumáticos y sistema de separador magnético → separador de fibras

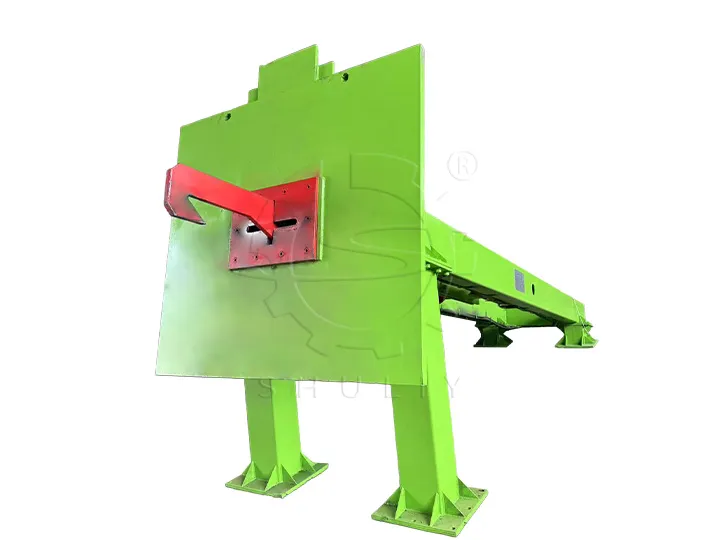

- Con una capacidad de 30 golpes/h, la máquina de trefilado de alambre OTR extrae de manera eficiente y completa los bordes de acero duro del bead de la rueda OTR, evitando así daños a los equipos de triturado posteriores.

- La máquina de corte OTR corta neumáticos grandes en secciones que se pueden introducir fácilmente en la trituradora para su procesamiento.

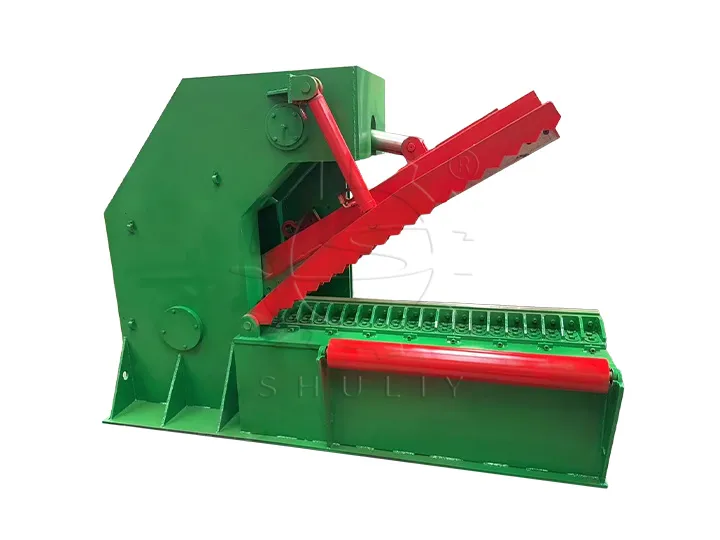

- La trituradora de neumáticos, que está disponible en varios modelos, tritura eficientemente el caucho en bloques uniformes de 50-100 mm, con una capacidad de 2-20 t/h.

- La máquina de molido de neumáticos muele bloques de goma en un polvo fino y produce un polvo de goma que cumple con los requisitos dimensionales al eliminar impurezas de alambre de acero fino mediante tamizado y separación magnética.

- El separador de fibra elimina aún más las impurezas de fibra.

Solución de Reciclaje de Neumáticos OTR 2:

Proceso de operación: desmantelador de neumáticos OTR → separador de alambre de neumáticos OTR → máquina de triturado de goma → trituradora de neumáticos y separador magnético → separador de fibra

- El desintegrador de neumáticos OTR corta neumáticos de minería en partes como la parte superior, el talón, etc. para su posterior procesamiento.

- La máquina separadora de alambre de acero OTR separa el aro de acero y el caucho de la pestaña del neumático, con una capacidad de 12-30 pcs/h, lo que es conveniente para el procesamiento posterior.

- Todas las partes de neumáticos de goma se introducen en la trituradora para su trituración.

- Los bloques de goma pasan por un proceso de trituración y molienda más fina, y se eliminan las impurezas de alambre de acero fino. Luego, los polvos de goma se tamizan para eliminar impurezas y alcanzar el tamaño deseado.

- El separador de fibra elimina las fibras.

Máquina de reciclaje de neumáticos OTR en venta

A medida que la minería y otras industrias continúan desarrollándose, el mercado de reciclaje de neumáticos OTR muestra un gran potencial y vale la pena invertir en él. Shuliy ofrece soluciones integrales, que incluyen personalización de equipos, planificación logística internacional, planificación del sitio, instalación puerta a puerta, orientación técnica y garantías postventa, etc.

¡Si quieres reciclar neumáticos OTR, no dudes en elegir a Shuliy como tu socio!