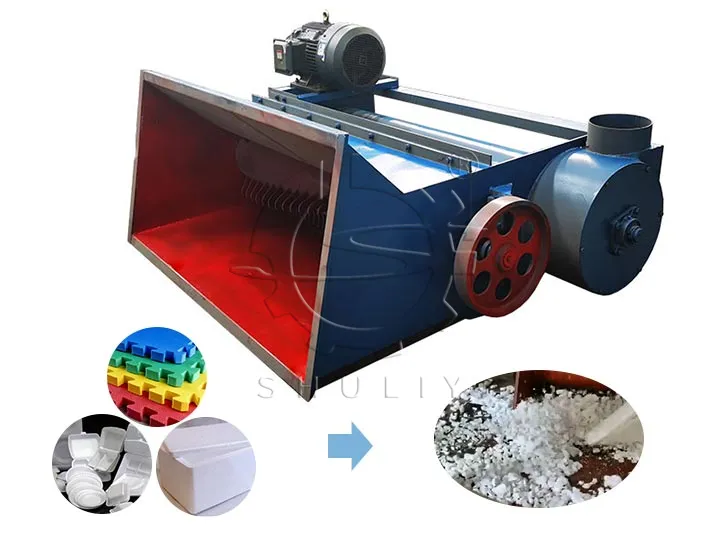

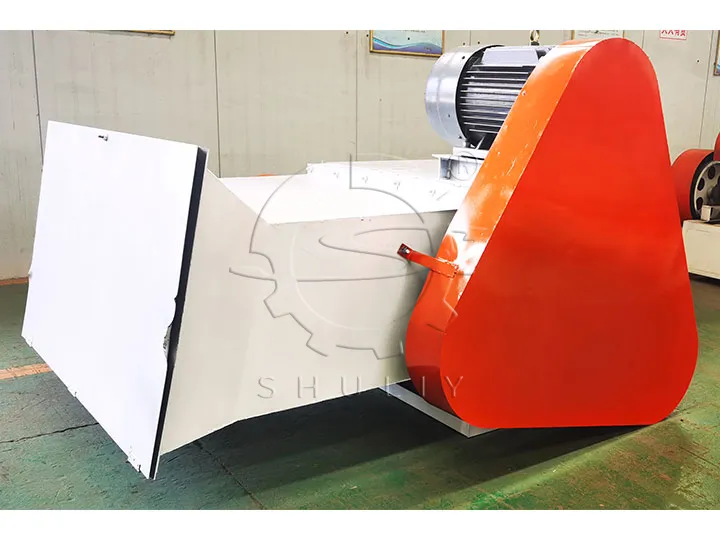

The Shuliy 250~500kg/h foam crushing machine can effectively process styrofoam into small pieces for recycling, which can be used for all sizes of factories and can be customized to satisfy your production needs. The machine details are as follows:

- Raw Material: EPE, EPS, XPS, PU, etc.

- Final Products: Foam flakes

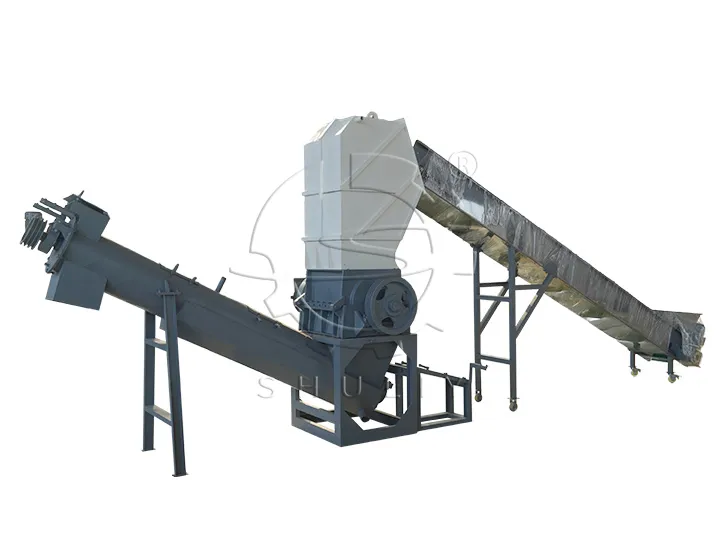

- Matching Line: Foam plastic recycling line

- Application Objects: Plastic foam recyclers and manufacturers

Why Foam-crushing Machine Is Needed?

- Volume Reduction: In the foam recycling process, foam products are usually bulky and take up a lot of space, causing inconvenience in recycling. By using a styrofoam cutter, bulky foam products can be crushed into smaller pieces, which significantly reduces their size and facilitates transportation and storage.

- Impurity Removal: By breaking large volumes of plastic foam, impurities such as paper, metal, and other contaminants can be removed efficiently, which ensures the purity of the recycled materials. In addition, the crushed foam is easier to recycle in the next step, which increases the overall efficiency of the recycling process.

Advantages of A Foam Shredder Machine

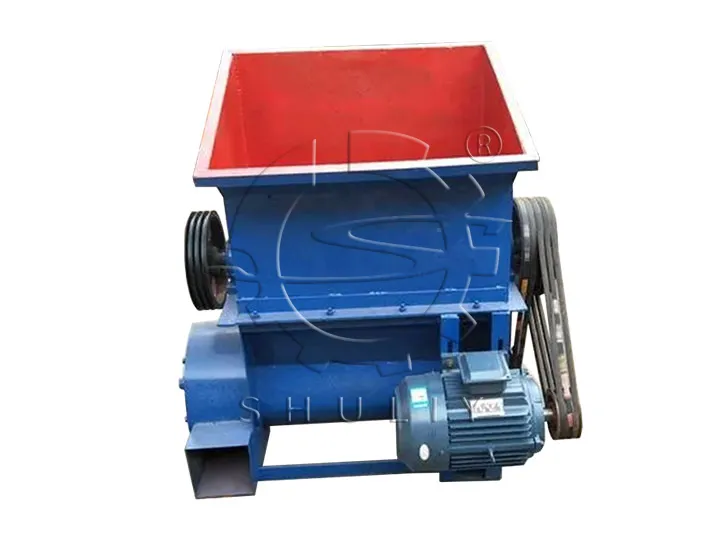

- High Efficiency: Equipped with a large capacity feed hopper and high-speed motor, our foam shredding machines can process up to 500kg/h, significantly improving recycling efficiency.

- User-Friendly Operation: The styrofoam shredder adopts an automatic design, minimizing labor costs and avoiding risks during production. At the same time, utilizing a control panel allows operators to control the shredder conveniently.

- Dust control: Equipped with effective dust removal systems, ensuring a clean operating environment and the purity of gained foam granules.

- Durability: Our polystyrene shredding machines are made of high-quality materials, such as 60Si2Mn, etc., which are durable, stable, and reliable.

- Long-term services: Shuliy is a professional plastic recycling machine manufacturer with more than ten years of experience and has exported machines to many countries worldwide. We promise that we can offer reliable long-term services.

Application And Raw Materials Of Foam Crusher Machine

Raw Materials

The foam crushing machine can process these raw materials: EPS Foam, EPE Pearl Cotton, XPS Extruded Panel, PU Foam, etc., which can be divided into two types: post-consumer foam, and post-industry foam plastic.

Post-consumer: waste foam from the packaging industry.

- Packaging foam in supermarkets

- Restaurant takeout boxes,

- Electronic product packaging

- Furniture packaging

Post-industry: Scraps or non-conforming products in the production process

- Foam manufacturers,

- Electronics manufacturers,

- Furniture manufacturers,

- construction sites

Final Products

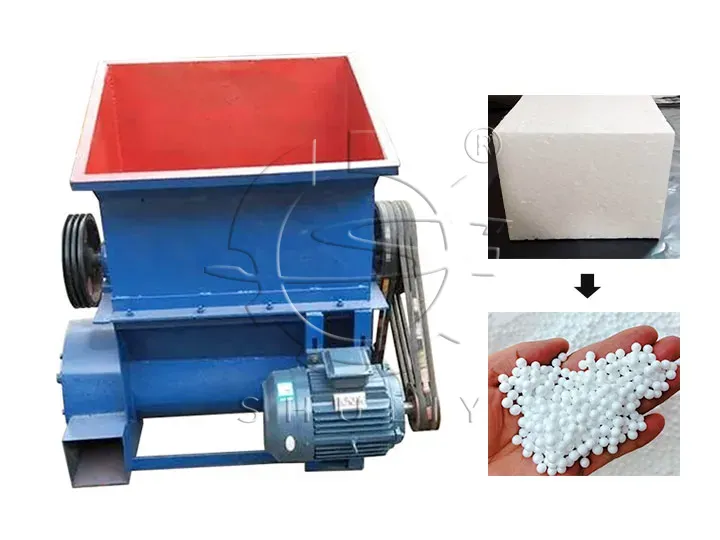

The final products of the styrofoam crushing machine are recycled styrofoam flakes, which offer enhanced convenience in terms of transportation and recycling.

What’s the Process of Foam Shredding?

Workflow of the Foam Crushing Machine

EPS foam shredder cuts and crushes the foam waste through the high-speed rotating blades, breaking down the large foam waste into fragments, to facilitate the next step of recycling.

- Feeding: The foam wastes are fed into the hopper of the styrofoam cutting machine and sent into the crushing chamber through the feed inlet. The hopper of the foam shredder has a large intake port, designed to accommodate various sizes of foam materials.

- Initial Crushing: Next, the blades made of No.45 steel break down the large foam plastic efficiently through high-speed rotation. In addition, the gap between the blades can be adjusted to produce satisfied foam particles in customers’ required size.

- Collection: After being cut and crushed by the plastic crusher blades, the ideal crushing effect is finally obtained. The qualified particles are discharged through an outlet and collected in a storage container or conveyed for further recycling processes.

- Dust Control: To minimize dust during the production processes, our plastic shredder is equipped with a dust removal system, which can ensure a clean operating environment.

The whole automatic working process is efficient, stable, and easy to operate, which can greatly improve the processing efficiency of foam waste. And with the different powers of the foam crushing machine, the corresponding capacities vary from 250-500kg/h.

Pre-shipment video

Before shipment, we will send the text run video of our machines to ensure smooth operation. Here is a feedback video from our client. You can see how a foam crushing machine works effectively. If you have any questions, please feel free to contact us.

Foam Crusher Machine Specifications

| Model | Contour size(mm) | Input size (mm) | Power (KW) | 产量(公斤/小时) |

| 800 | 1250*1290*660 | 800*600 | 5.5 | 250-300 |

| 1000 | 1250*1530*660 | 1000*600 | 5.5 | 300-350 |

| 1200 | 1300*1730*700 | 1200*600 | 7.5 | 400-450 |

| 1500 | 1600*2200*800 | 1500*800 | 11 | 450-500 |

Above are the hot-selling foam crushing machine models in Shuliy. Each type of foam crushing machine has a different size, power, and capacity. According to your own production needs, you can choose the most suitable model of foam plastic shredders.

Besides, as a professional foam crushing machine supplier, shuliy also offers various foam cutters with other customized models. If you have other needs for production output, please feel free to contact us for customized crushing solutions.

Long-term Services Of Foam Plastic Crushers

- Pre-sales: Before purchase, our professional sales manager offers the details about our machines and consultation services tailored to each customer’s needs, helping them select the most suitable products.

- On-sales: We provide timely counseling services solving customers’ questions and detailed technical information on foam plastic crushers.

- After-sales: We promise a one-year warranty at no extra cost and on-site installation service. If there are some bad parts of the machine, it can be re-sent by express delivery.

EPS Foam Shredder For Sale

Welcome to purchasing our plastic foam crusher! We specialize in providing all kinds of efficient and reliable plastic foam crushers to help you quickly crush waste plastic foam, thus reducing storage and transportation space, lowering costs, and improving the productivity of plastic foam recycling lines. Contact us today to get the best quote and choose the right foam crushing machine for you!