The Shuliy plastic friction washer utilizes the principle of friction to achieve efficient deep cleaning of plastic fragments through the synergistic action of a high-speed rotating impeller and a powerful water flow. It is designed to deal with various impurities on PET bottle flakes, which plays a vital role in PET bottle recycling plants.

- Capacity: 500~2000kg/h

- Function: Wash PET bottle flakes

- Application: PET bottle recycling line

Advantages of the Shuliy Friction Washing Machine

- Durable Design: Utilizing 304 stainless steel, our friction washers are extremely corrosion-resistant and durable, which can withstand several years.

- Flexible Adjustment: The adjustable propeller blade speed and water flow jet velocity can be adapted to different cleaning requirements.

- Low Power Consumption: Placing it at a 45-degree angle maximizes the frictional effect, while the use of water spouts reduces water resource wastage.

- Adaptable to Existing Plants: As a professional plastic recycling machine supplier, Shuliy can provide various plastic recycling lines for different production environments and needs. We also offer customized services to assist customers choose the most suitable purchase method.

What can Friction Grip Washers be Used For?

Raw Material

- The friction washing machine is typically utilized in PET bottle recycling lines.

- It can also clean crushed PP PE plastic flakes, such as PE agricultural film, domestic waste nylon film, industrial waste stretched film, cement bags, snakeskin bags, space bags, etc.

- Especially for the agricultural film with large sediment content, the sand removal effect is more obvious.

Application

- The friction washer plastic recycling machine is specially designed for further cleaning PET bottle flakes.

- The combined action of friction and rinsing efficiently removes dirt and impurities from the surface of PET bottle flakes, including residual liquids, food residues, and other contaminants.

- This type of washer typically utilizes a multi-stage cleaning process and follows a hot washing tank to ensure that PET bottle flakes are thoroughly cleaned to meet strict recycling standards.

Parameters of Plastic Bottle Washing Machine

The friction washer plastic recycling is a highly effective washing device with a wide range of parameters to choose from, below is information on the data of our hot-selling friction cleaner.

In addition, we have more models available that can be customized to meet specific customer requirements to meet a variety of different cleaning needs and improve the efficiency of plastic recycling.

| Model | SL-1000 | SL-2000 |

| Capacity(kg/h) | 500-1000 | 2000 |

| Length(mm) | 3000 | 3500 |

| Power(kW) | 7.5 | 1.5 |

| Out layer(mm) | 4 | 4 |

| Blade thickness(mm) | 6 | 6 |

*CE certification available

Structure of Friction Washing Machine

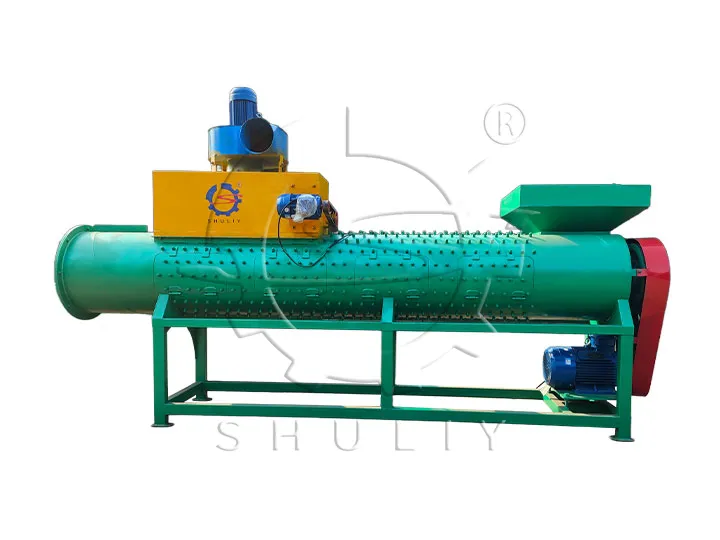

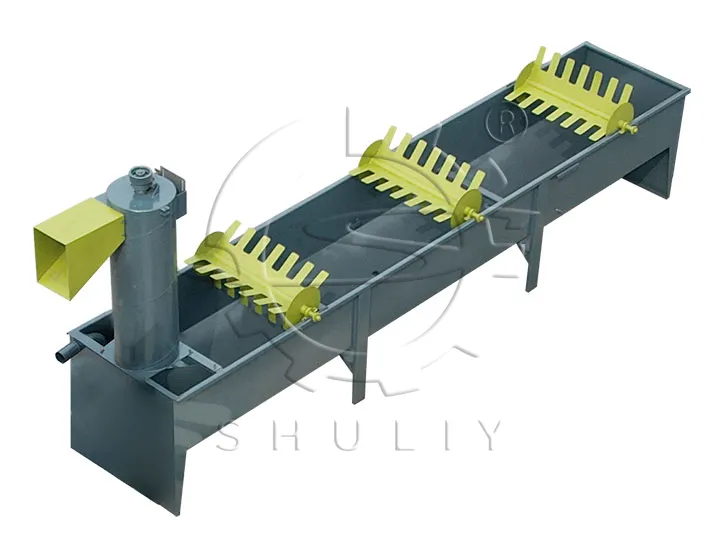

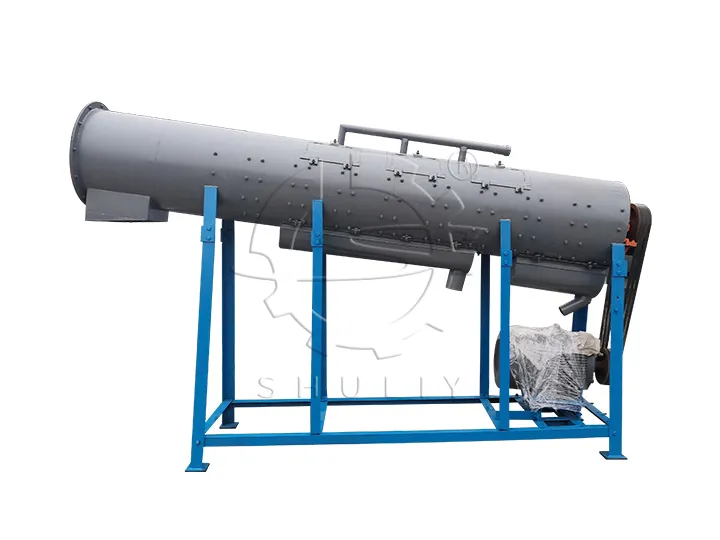

- The overall appearance of the friction cleaning machine is cylindrical and inclined, facilitating water circulation and impurity separation.

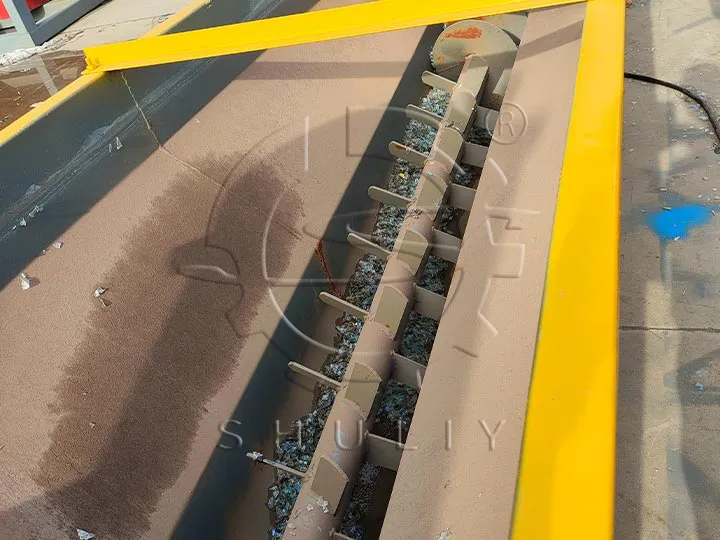

- The inner core consists of a long shaft with high-speed rotation and numerous blades, supported at both ends by bearings and encased in a dismountable filter net.

- Both filter net and shaft are housed in a robustly manufactured frame. If necessary, an additional protective casing can be installed outside the cylindrical slot.

- In addition, the machine is equipped with numerous water nozzles that spray water, effectively conserving water.

When working, the material enters the machine body through the feeding port, and under the action of the high-speed rotating screw, it is fully rubbed with the flowing water to achieve the purpose of thorough cleaning. This structural design makes the friction cleaner able to process all kinds of materials quickly and effectively, and it is widely used in plastic bottle recycling plants.

How Does a Friction Washing Machine Work?

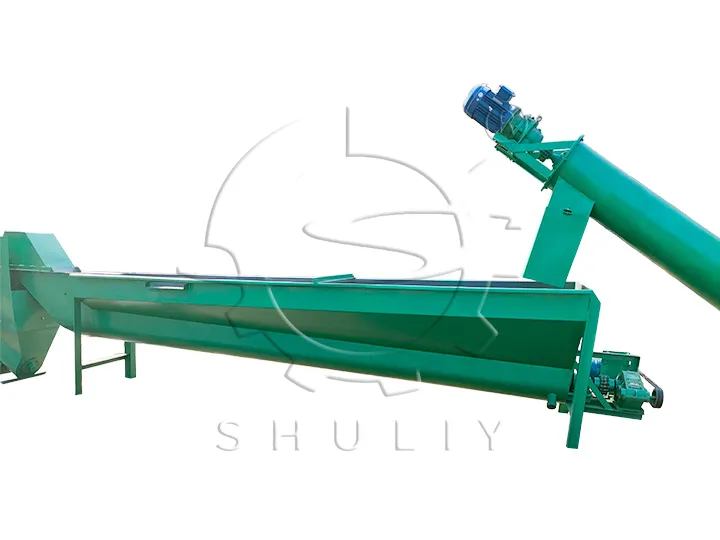

- The friction cleaning machine is placed at a 45-degree angle and the dirty plastic stream enters into the chamber from the bottom.

- Water jets spray water while the motor drives the impeller to rotate at high speed.

- As a result of friction between the impeller and screen, impurities such as labels, soil, sand, dust, etc. are removed and discharged from the bottom of the machine during cleaning.

- Meanwhile, clean plastic fragments are conveyed to the top outlet during this rotation process.

The entire process is highly efficient and energy-saving, as it not only achieves deep cleaning of dirty plastic through the dual action of friction and water flow but also utilizes a water recycling system to reduce water waste.

Shipping Information about the Plastic Bottle Washing Machine

After placing the order, it usually takes 20~25 days to deliver the machine to you via international logistics. Before delivery, we will send a test video to make sure the machine is working properly. After delivery, if there is any problem with the machine, please contact us the first time, we provide a one-year warranty!

Here share a test run video to demonstrate how a plastic friction washer works. Welcome to inquire.

Related PET Bottle Recycling Machines

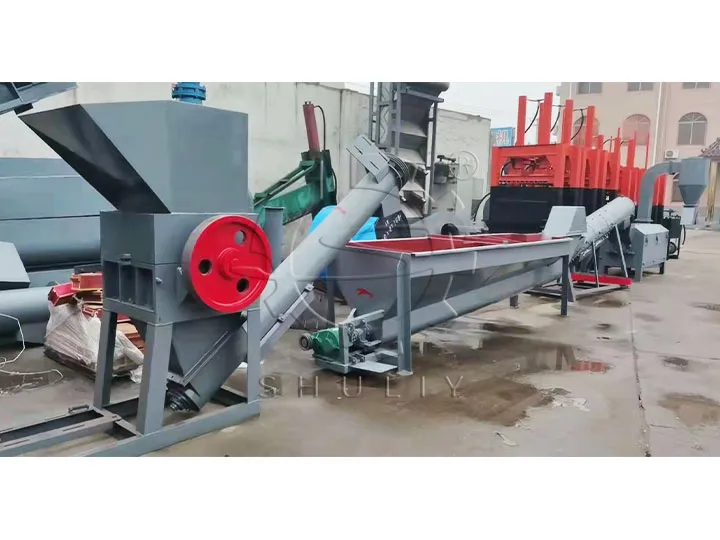

Shuliy high-speed friction washer is an important part of a plastic bottle washing line, along with plastic label removal machines and PET bottle crushers.

Suppose you want to upgrade your existing recycling equipment or start your own plastic recycling business. In that case, a productive plastic bottle washing machine can greatly improve the efficiency of your recycling process. Please contact us for more details, we look forward to serving you.