Do you know how to recycle plastic lumber effectively? The processes involve collecting, crushing, washing, pelletizing, and drying and can achieve a capacity of 100~500kg/h. Read the article to learn details and please feel free to contact us if you have questions.

Why Do We Recycle Plastic Lumber?

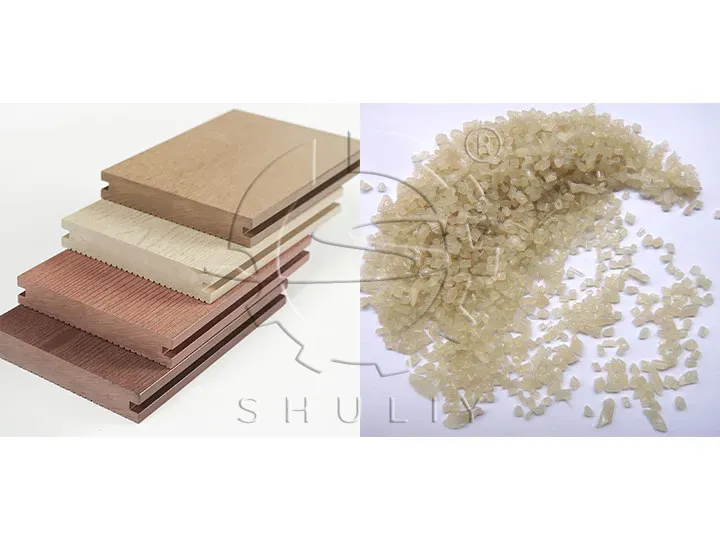

Made of PP, HDPE, LDPE, etc., and compared to conventional woods, plastic lumber features waterproof, corrosion-resistant, pest-resistant, and easy maintenance, which can be widely used in construction, outdoor landscapes, etc. with high utilization and recycling value.

Through recycling, it can be transformed into recycled plastic lumber and other valuable plastic products, which also has the above advantages while avoiding pollution, reducing costs, and facilitating circular economic development. The article explains how to recycle plastic lumber effectively.

Plastic Lumber Recycling Processes

Plastic lumber recycling processes involve collecting, crushing, washing, pelletizing, and drying. These steps transform waste plastic lumber into high-quality pellets, which can then be used to create new plastic products.

The detailed explanations about how to recycle plastic lumber are as follows:

Collecting&Crushing

- Firstly, collect plastic lumber from plastic decking boards, outdoor benches, furniture, etc.

- Then, crush them into small fragments around 20~26mm diameters to more conveniently transport and recycle. By adjusting the gap between the movable and fixed knives of the plastic crusher, you can get different sizes of plastic timber pieces.

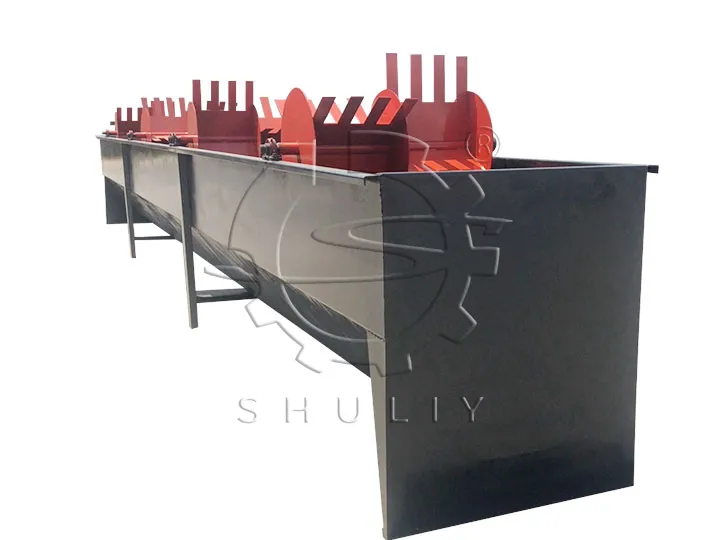

Washing

The gears of the washing tanks rotate rapidly to push water. The circular water flow bit plastic fragments rushing dirt, sand, and other impurities. Based on the dirtiness and required output of raw materials, the number of washing tanks can be adjusted, generally, two is enough.

The Shuliy washing tank has a capacity of 100~500kg/h.

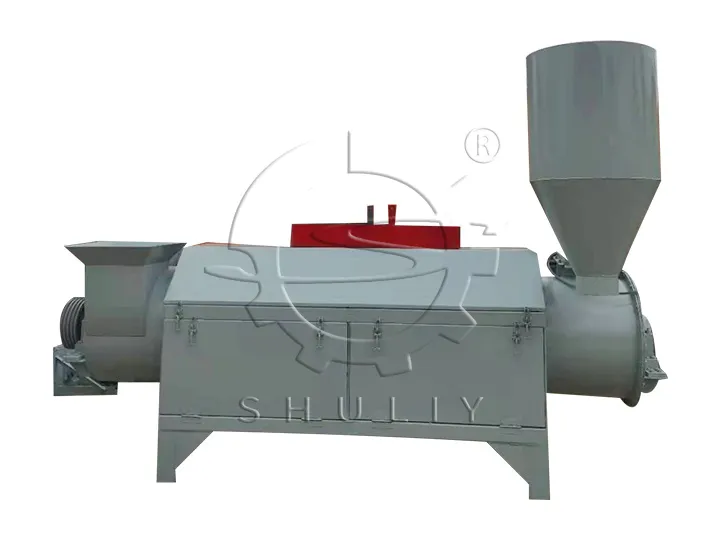

Pelletizing

After crushing and cleaning, the lumber fragments are processed by a plastic pelletizer machine to create recycled plastic pellets. The granulation processes include melting, shaping, cooling, and cutting.

- Melted and extruded by the plastic extruder, plastics are converted into melted state and shaping long strips.

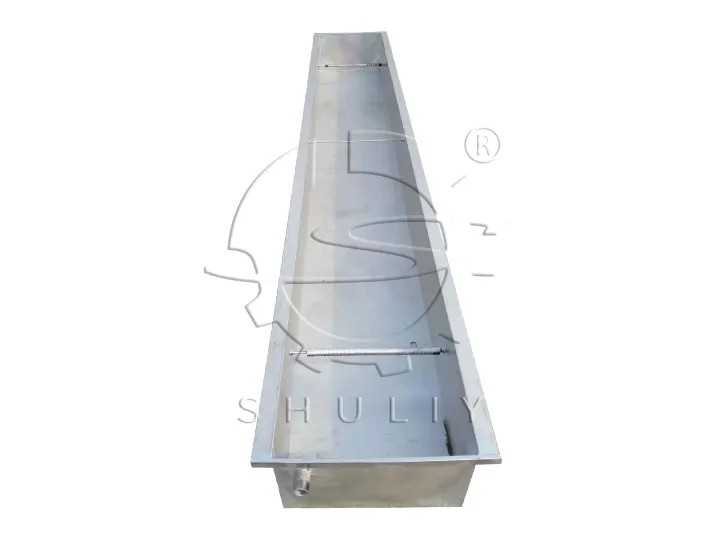

- Then, strips across the cooling tank to shape.

- Finally, a plastic pellet-cutting machine cut them into uniform pellets.

Using the Shuliy granulator, you can achieve production at a speed of 180~420kg/h.

Drying

Due to the cooling process in water, the plastic pellets obtained were wet and had to be dewatered in a drying machine. There are two types of drying machines, known separately as vertical dryers and horizontal drying machines.

Capacity: 1000kg/h

What Can Recycled Plastic Lumber Used for?

Recycled plastic wood also retains the properties of the raw material and can be used as a raw material for many fields, such as:

- Home Decoration Materials

- Amusement parks

- Warehouse

- Decking

- Fence

- Bench

In addition, during the recycling process, the plastic is modified through physical or chemical reactions, which can extend the range of applications for the plastic.

Conclusion

In short, plastic lumber recycling has many advantages. If you’re considering purchasing plastic lumber machines, we recommend Shuliy plastic recycling line for PP, PE, LDPE, HDPE, etc., which can achieve a capacity of 200~3000kg/h. We can also provide customized machines with other capacities and help you solve all of your problems. Clicking the right bottom link, we’re waiting for your news!