As a green circular economy practitioner and pioneer, Sweden has persistently advocated plastic recycling and reducing plastic waste. Recently, a Shuliy plastic pellet machine in Sweden has been successfully helping our customer recycle post-industrial waste, promoting economic development.

Story Of Our Client: A HDPE Pipe Manufacturer

This customer manufactures HDPE pipe and PP packaging. The plastic pipe extrusion process generates a lot of waste. Therefore, our customer was looking for a suitable recycling solution to reduce costs and increase efficiency by recycling this waste.

These scraps are irregular in shape and size, but with physical properties that are generally the same as the finished product. It is a real shame to throw them away, and they burden the environment by adding to the amount of plastic in landfills – not in line with the green developmentalism of the customer.

Customer’s needs and outlook

The customer requested new plastic recycling machines, such as a plastic pellet machine in Sweden capable of efficiently converting HDPE trimmings into uniform pellets. These pellets are intended for direct use in the production of new plastic pipes, facilitating easy recycling within the plant.

Additionally, due to site constraints, the customer specified the need for machines that are quick to operate, require less manpower, and simplify the operating process.

What can we do for the plastic trimmings recycling?

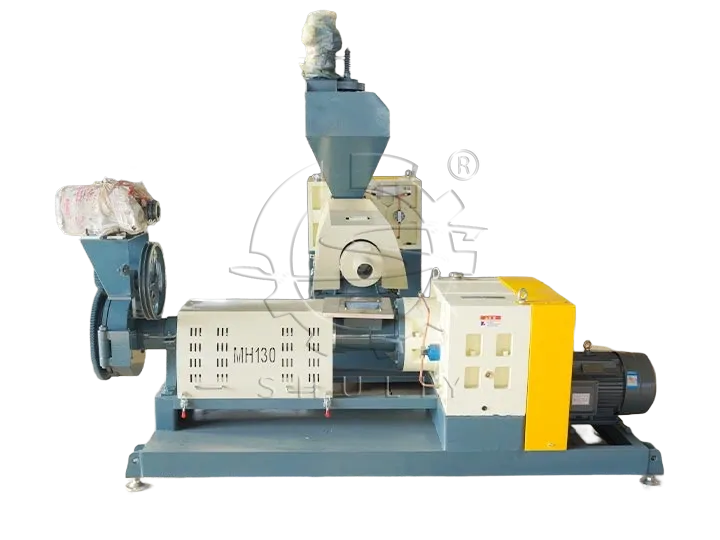

After assessing the customer’s needs, our sales manager suggested a heavy-duty plastic crusher and granulator with a water ring-cutting system. They are designed for the efficient crushing and granulating of hard plastics. The sales manager also shared videos demonstrating the operation of both the plastic crusher and granulator with the customer.

Our plastic crushers and granulators are famous for high efficiency and low energy consumption. The heavy-duty crusher blades are designed with large-size feed ports without jamming or clogging; the granulators are equipped with intelligent cabinets for easy control of the temperature of the granulation process. Besides, the water ring cut pelletizing guarantees the smoothness and uniformity of the granules.

Plastic Pellet Machine in Sweden

Shuliy plastic crusher and plastic pellet machine in Sweden is finally ready to be put into plastic recycling after production, debugging and installation. The customer said: “With the new recycling equipment, the plastic resources in my factory have been fully and effectively utilized!”. We are glad to meet our customer’s production needs and help him to recycle plastic resources.

The cycle continues, plastic resource thrives. Never underestimate the impact of post-industrial waste recycling—small efforts accumulate over time, ultimately yielding significant economic benefits and environmental gains! If you’re interested, please feel free to contact us and we will design the most suitable recycling solution for you.