Recently, a customer from Côte d’Ivoire, who specializes in plastic recycling, purchased plastic pellet making machine from Shuliy to increase production and solve the problems of the existing machine. The advanced plastic pelletizing line has been successfully put into operation in the customer’s factory, and the customer is very satisfied with Shuliy’s equipment and service.

Client background and needs

This customer from Côte d’Ivoire specializes in plastic recycling and already owns a set of plastic pelletizing equipment, but with the increase in market demand, the capacity of the existing equipment can no longer meet the production demand. In addition, the existing plastic granulation equipment encountered some technical problems during operation, which affected production efficiency and product quality. Therefore, this company decided to look for more advanced, efficient and stable plastic pellet making machine to increase production and solve the problems of the existing equipment.

Customer tour of the Shuliy extruder plastic machine factory

In order to ensure that the selected equipment would meet the company’s needs, the Ivorian customer organized a team to travel to China and visit Shuliy plastic recycle machine extruder factory. During the visit, the customer learned about the production process and technical parameters of plastic pellet making machine and watched the operation of the equipment on site, Shuliy’s engineers patiently answered the customer’s questions and proposed customized solutions to meet the customer’s specific needs.

After visiting the factory, the customer highly praised Shuliy’s recycling equipment and service. After returning to Côte d’Ivoire, in order to further increase the customer’s trust, Shuliy also promptly showed the production environment and plastic pellet making machine operation of the factory to the customer using videos and pictures. These videos enabled the customer to understand the performance of plastic pellet making machines and the production process more intuitively, laying a solid foundation for the final cooperation.

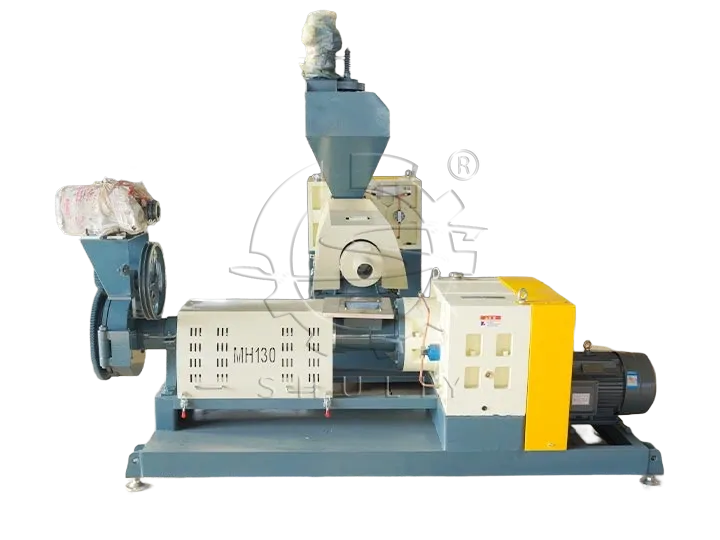

Parameters of plastic granulation equipment

| Item | Specification | Item | Specification |

| Conveyor belt | Length(m): 5 Width(m): 1 Power(KW): 2.2 With magnetic roller | Plastic crusher | Model: SLSP-600 Motor power(KW): 30 Capacity(kg/h): 600-800 10pcs knives Material of knives: 60Si2Mn |

| Double tank cleaning machine & heating tube | Motor power(KW): 7.5 Dimensions(m): 5.0*1.4*1.6 Diameter(m): 0.6*2Blade Thickness(mm): 10 Outer wall thickness(mm): 4 Material: Q235 Heating power(KW): 60 | Plastic pelletizer | Host pellet making machine Model: SL-150 Power(KW): 37 2.3screw Heat method: ceramic heating Hardened gear reducer Second pellet making machine Model: SL-125 Power(KW): 11 1.3m screw Heating method: heating ring heating Hardened gear reducer Screw material: 40Cr(High hardness and wear resistance) Sleeve material: heat-treated No.45 steel Double Hydraulic die Power(KW): 3(Change net non-stop machine) |

| Vertical plastic dryer | Motor power(KW): 7.5 Dimensions(m): 2.6*0.7 Diameter(m): 0.5 Weight(KG): 450 Blade thickness(mm): 6 Outer wall thickness(mm): 4 Material: Q235 | Plastic washing tank | Motor power(KW): 4 Dimensions(m): 4.5*1.2*1.3 Power of the gear motor(KW): 1.5 Weight(KG): 1200 Blade thickness(mm): 6 Outer wall thickness(mm): 3 Material: Q235 |

| Horizontal plastic dryer | Dryness: 98% Motor power(KW): 15 Dimensions(m): 2.5*1.0 Screen: made of 304 stainless steel Blade thickness(mm): 10 Spindle thickness(mm): 8 | Plastic pellet cutter | Converter speed regulation Power(KW): 3 Hob knives |

| Cooling tank | Length(m): 3 Material: stainless steel | Storage bin | Power(KW): 2.2 A high-pressure blower delivers the pellets and removes the water from the pellets. |

Above is the information about the parameters of the plastic pellet making machine customized by the customer in Côte d’Ivoire. We also provide various types and specifications of plastic recycling machines to meet different needs, if you need, please feel free to contact us.

Plastic pellet making machine shipped to Cote d’Ivoire

After a period of in-depth communication and detailed discussion, the Ivorian customer finally decided to purchase Shuliy’s industrial plastic granulator, and Shuliy quickly arranged for the production and commissioning of the equipment to ensure that the equipment was shipped to the customer’s factory in the best condition. Shuliy plastic pelletizing recycling machine was shipped to Cote d’Ivoire after strict quality inspection.

Putting plastic pelletizing recycling machine into operation

After the plastic granulation equipment arrived at the customer’s plant, Shuliy sent a professional technical team to the site to carry out installation and commissioning work. After several days of commissioning, the equipment was successfully put into operation. The customer is very satisfied with the efficiency and stability of the plastic pellet making machine. The new plastic pelletizing line not only improves the production capacity of the company but also effectively reduces the failure rate of the equipment, which greatly improves production efficiency and product quality. If you are also looking for efficient and reliable plastic pelletizing equipment, please feel free to contact us.