As the cornerstone of the green economy and circular economy, RPET plastic plays an important role in many fields, not only protecting the environment but also greatly reducing production costs.

What is rPET?

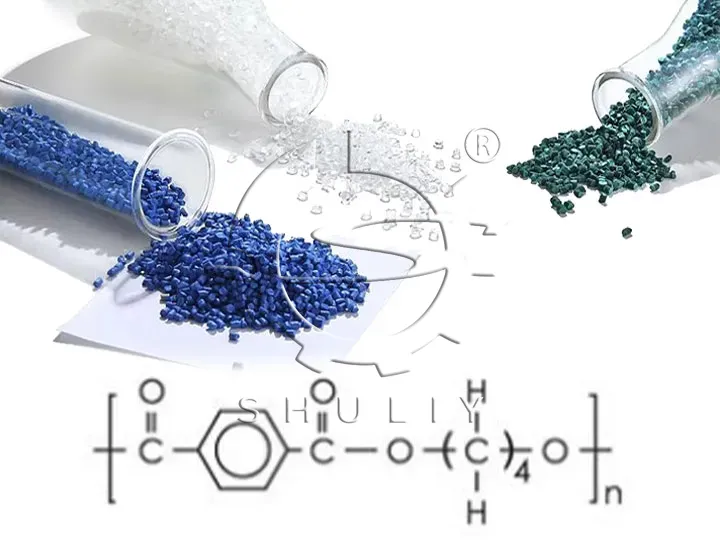

RPET stands for “recycled PET,” which is a form of polyethylene terephthalate (PET) that is created by recycling and processing waste PET materials. Through recycling and pelletizing of waste PET, we can finally obtain uniform high-quality pellets, and the pellets are the raw materials for creating rPET materials.

With the promotion of green and circular economy concepts, rPET plastic is playing an important role in plastic production due to its low cost and high utilization value. By using rPET, not only can we reduce the amount of discarded plastic that enters the natural environment and protect the environment, but we have also successfully transformed waste into valuable resources, thereby lowering the cost of product production.

The Wide Application of RPET

As we all know, PET is commonly used in food packaging, electronic product shells, beverage bottles, etc. So what can rPET be used for after being recycled from existing PET?

- Packaging: Like PET, rPET plastic also has transparency, heat resistance, etc., so it can be used to make beverage bottles, food containers, packaging films, and so on. However, it is worth noting that for food-grade Rpet, strict safety monitoring and sterilization procedures are required.

- Textiles: One of the most common applications is in textile manufacturing. RPET fibers are more environmentally friendly than regular polyester fibers, so many fashion brands choose rPET to make clothes, backpacks, shoes, carpets, curtains, etc. The application of RPET offers a sustainable alternative to traditional polyester.

- Construction: The rPET plastic can be used to manufacture plastic floor tiles and insulation materials.

- 3D Printing: With the development of 3D printing technology, RPET is becoming increasingly popular in the industry as a sustainable printing material option.

RPET plastic can be used in various fields and it will also have greater development potential in the future.

The Difference of PET and RPET

- The Sources are Different: PET is a raw material that is derived directly from petroleum. While rPET is more environmentally friendly by recycling and reprocessing used PET products.

- Environmental certification: rPEt is more environmentally friendly because it is recycled and some high-quality RPET materials are subject to strict environmental certification to ensure that they do not harm the environment or people.

What Can Shuliy Do for RPET?

RPET is an important element in achieving sustainable development. With the rise of environmentalism, there will be increasingly broad applications. ShuliY is committed to providing top-of-the-line plastic recycling machines to contribute to the production of rPET. As a plastic recycling specialist, Shuliy provides a variety of professional PET recycling machines, which can produce high-quality pellets as the raw materials of rPET. If you’re interested, please feel free to contact us.