In the tire recycling industry, separating steel wire from scrap tires is a critical first step in achieving clean rubber output and preparing materials for further granulation. The tire wire removal machine, also known as a tire steel wire separator, is a high-efficiency solution designed to extract bead wire from used tires with minimal rubber loss. This machine plays a vital role in modern tire recycling lines, ensuring operational efficiency and improved output quality.

What Is a Tire Wire Removal Machine?

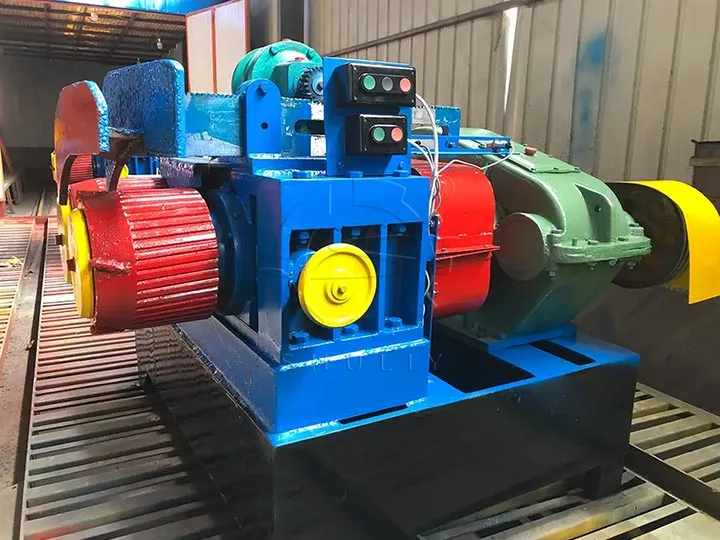

A tire wire removal machine is an industrial device engineered to isolate the embedded steel wires from tire beads. Tires, especially truck and OTR types, contain strong inner rings reinforced with steel. These rings—known as bead wires—are not only valuable for recycling as scrap metal but also must be removed before further shredding or grinding.

By employing dual rotating rollers, the machine cuts, squeezes, and shears the tire bead to effectively separate the wire without damaging the surrounding rubber. The extracted steel wires can then be sold separately, adding extra revenue to recyclers and protecting downstream machines from wear and damage.

Specifications of the Tire Steel Wire Separator

Our tire steel wire separator comes equipped with:

- Model: SWS-100

- Motor Power: 18.5 kW

- Capacity: 120 tires/hour

- Dimensions: 2m*1.9m*1.8m

- Weight: 1800 kg

This machine is capable of handling a wide range of tire sizes, from passenger cars to heavy-duty truck tires, making it an excellent fit for both small and large-scale operations.

How Does the Tyre Steel Wire Separator Work?

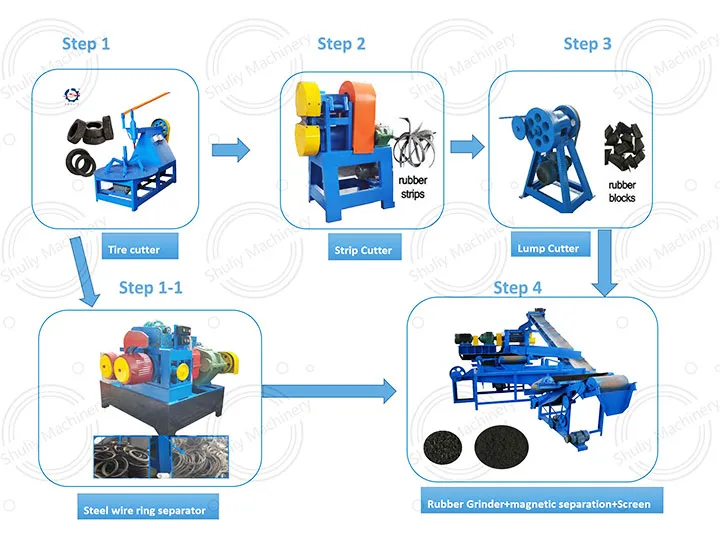

The working principle of the tire wire removal machine is straightforward yet highly effective:

- Tire Loading: Operators manually insert the tire bead into the space between two counter-rotating rollers.

- Mechanical Separation: As the rollers turn, they grip and compress the tire bead. Through a combination of shearing, squeezing, and tearing, the steel wire is gradually separated from the rubber.

- Output Collection: The separated steel wire exits through a designated chute, while the rubber is left wire-free, ready for the next stage of processing.

The simplicity of this process reduces labor requirements and improves safety, making it a valuable asset in any tire recycling plant.

Benefits of Using the Tire Bead Wire Remover

- Protects Downstream Equipment: By removing steel in advance, the machine prevents damage to tire shredders, granulators, and grinders.

- Increases Scrap Value: Extracted steel can be sold as high-quality scrap metal, adding revenue potential to your operation.

- Improves Processing Efficiency: Cleaner rubber ensures smoother operation in later processing stages, including tire granulation and rubber powder production.

- Compact & Durable Design: The tire steel wire separator features a compact footprint, rugged steel structure, and low maintenance requirements.

Ideal for Semi-Automatic and Fully Automatic Tire Recycling Lines

Whether integrated into a semi-automatic tire recycling line or a full automatic tire recycling plant, the tire steel wire separator ensures clean material flow and optimized machine protection. It’s also a key component in OTR tire recycling lines, where stronger and thicker steel wires require powerful mechanical separation.

Who Should Use a Tire Wire Separator?

This equipment is highly recommended for:

- Waste tire processing plants

- Rubber recycling companies

- Scrap metal recovery businesses

- Government-funded environmental cleanup projects

- OTR (off-the-road) tire recyclers

If your facility handles more than 100 tires per day, investing in a tire bead wire remover is not just cost-effective—it’s essential.

Conclusion

The tire steel wire separator is a cornerstone of efficient tire recycling operations. With powerful design, reliable separation capability, and proven durability, this machine significantly contributes to cleaner rubber output, safer processing, and higher profits. Whether you’re launching a new recycling line or upgrading an existing one, the tire wire removal machine is an investment that delivers long-term value.