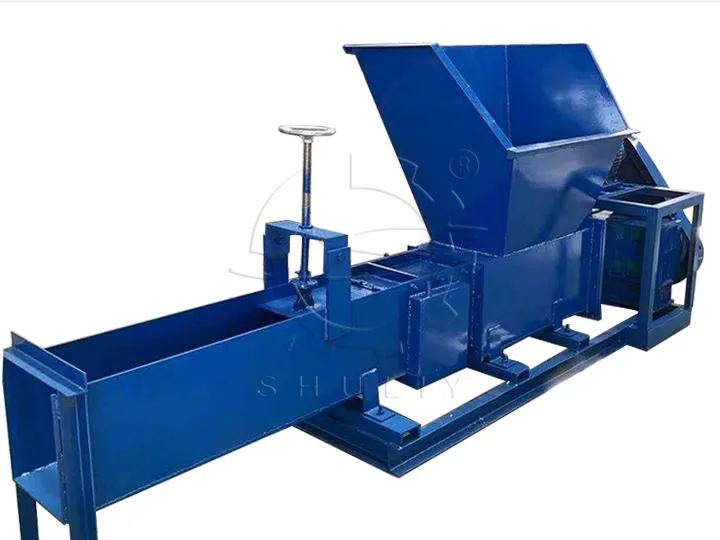

The vertical EPS foam compactor is a machine specially designed to compress foam materials by placing large pieces of foam inside the machine, applying high pressure, and utilizing a special cold pressing technique that gradually compresses the foam into a more compact form, thus saving space for storage and transportation. The compression ratio can reach 40:1, which plays a crucial role in the foam recycling plant.

Features of Foam Compactor Machine

- Good Compression Effect: EPS cold compactor adopts advanced compression technology, which can compress the foamed plastic material to a very high ratio, usually up to 1:40 compression ratio, thus significantly reducing the volume of the material and saving the storage and transportation space.

- Small Footprint: Foam compactor machines are usually compact and simple in design, with a relatively small footprint. This makes it suitable for use in a variety of locations, saving production space costs.

- Customizable: Vertical EPS foam compactors can be customized according to specific customer needs, including the adjustment of compression ratio, pressure, molding shape, and other parameters. This customized design can better meet the production needs of different customers and improve production efficiency and product quality.

Application

Raw Materials

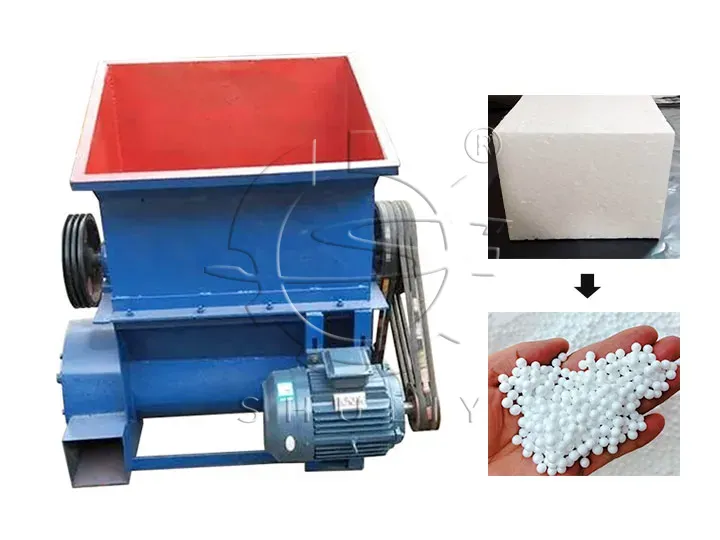

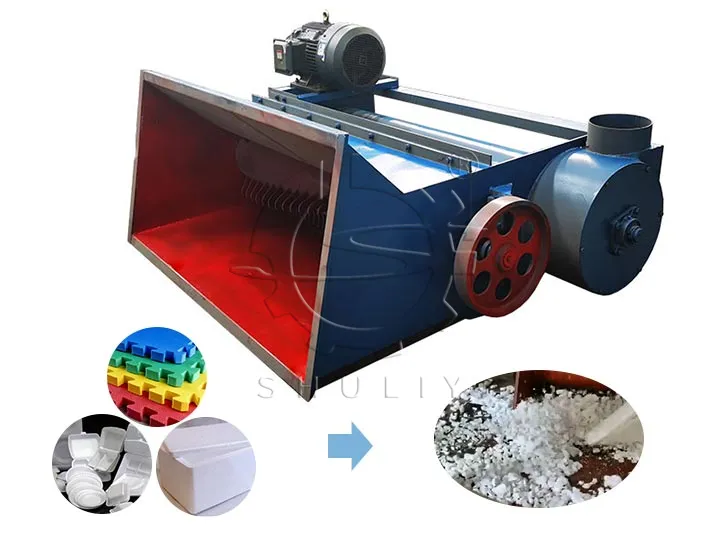

The vertical EPS foam compactor can be used to compact various kinds of plastic foams, such as the following:

- EPS: Foam boards, foam cups

- EPP: Packaging materials

- EPE: Protective packaging materials and insulation materials.

- PU: Insulation materials and household products.

- Other Compressible Foam Plastics: Including various packaging and insulation materials.

Compacted Products

The raw materials mentioned will be shaped into tight ingots for the subsequent pelletizing process by compression. These pellets can be applied in the fields of building, food, electronic product industry, etc.

Parameters of Styrofoam Compactor

| Machine model | Machine size (mm) | Inlet size (mm) | Machine power (KW) | Capacity (KG/H) |

| 300 | 3000*1400*1400 | 1100*800 | 11 | 150 |

| 400 | 4600*1600*1600 | 1200*1000 | 22 | 250 |

These are two models of Shuliy’s hot-selling vertical EPS foam compressor. We also offer various models of horizontal EPS foam compactor to meet the different needs of our customers, and you can always contact us to customize the size and output of your machine.

Working Principle of Vertical EPS Foam Compressor

EPS foam cold pressing machine is a machine for processing foam materials that works simply and efficiently.

- First, the foam to be processed is put into the EPS foam compactor hopper.

- Then, the compactor machine will compact the foam. During this process, if the foam is large, it can be crushed by a foam crusher beforehand.

- As the compaction proceeds, the foam will be gradually compressed and extruded into blocks, eventually forming dense foam blocks. This cold pressing technique can effectively handle the foam material, making it easier to store and transport, while improving the utilization of the foam material.

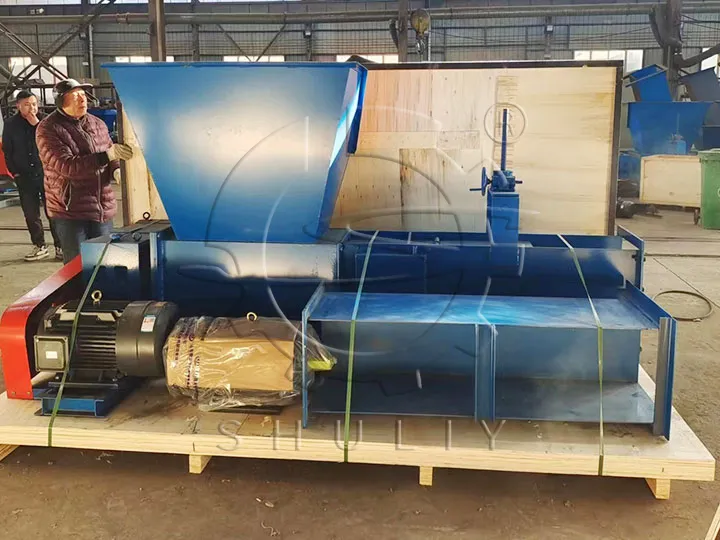

Successful Vertical EPS Foam Pressing Machine Transaction Case

EPS Cold Compactor Sent to America

A customer from America purchased an EPS foam cold pressing machine from our company. They were facing the problem of inefficient foam recycling. Our EPS foam compactor provided them with a solution that greatly improved their production efficiency by increasing the speed and quality of the compressed foam.

EPS Foam Cold Pressing Machine Price

Welcome to learn about vertical EPS foam compactor prices! We offer several models of foam cold presses, with prices varying by model, size, and features. Feel free to contact us and we will provide you with a detailed quote and professional advice based on your specific needs.