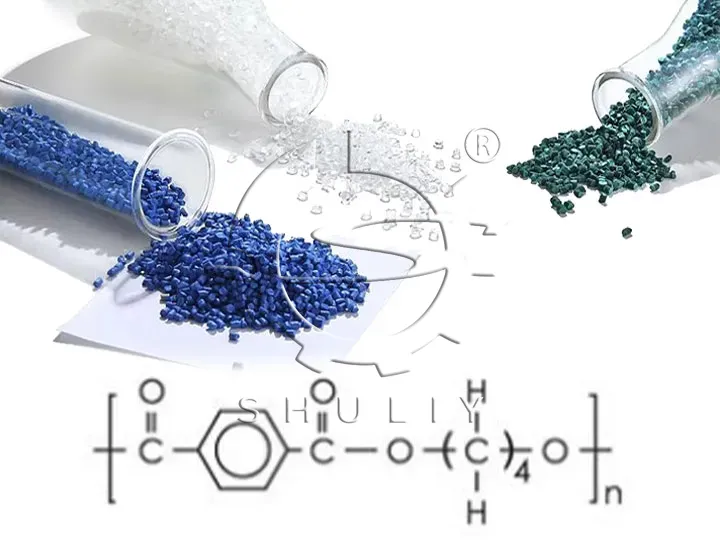

What are Recycled Plastic Pellets?

The recycled plastic pellets are produced from post-consumer or post-industrial plastic waste, which undergoes processes such as washing, shredding, melting, extrusion, cooling, cutting, etc. They are important products of the plastic recycling process for subsequent reproduction.

Importance of the Plastic Pelletizing Process

Improve Recycled Plastic Quality

- Ensure the Purity of Plastics: During the granulation process, impurities in plastic are removed through steps such as melting filtration multiple times to ensure the purity and quality of the final plastic product.

- Improved Performance: By adding modifiers during the recycling process, the physical properties of the recycled plastic granules can be enhanced, such as resistance to high temperatures and creep.

Convenient for Storage and Transportation

- Save Storage Space: By granulating, large pieces of plastic are transformed into tiny particles, greatly saving storage space for easy storage and reducing operating costs.

- Convenient for transportation: Smaller plastic pellets are more convenient for bagging and transportation, and are less likely to be damaged or contaminated.

Wide Market Demand

- High Market Acceptance: Plastic granules, due to their standardization and consistency, are the most common commodity form in the recycled plastic market.

- Wide Range of Applications: It can be widely used to manufacture various plastic products, such as packaging materials, building materials, and appliance shells.

Compliance with Regulations:

- Comply with Policy: The requirements for plastic production and recycling vary by region. After being granulated, plastic is more in line with environmental regulations in various regions and can be more widely used in various manufacturing industries.

- Promote environmental protection: transforming waste plastic into renewable plastic and reducing the incineration of plastic waste, thus reducing environmental pollution.

Economic Benefits

- High Product Value: Low-value discarded plastic is transformed into high-quality recycled granules, significantly increasing the product value and bringing in more revenue.

- Reduce Production Costs: Recycled plastic has a cost advantage over virgin plastic.

What are Recycled Plastic Pellets Used For?

Plastic granules are intermediate products in the plastic recycling and manufacturing industry, which can be used in various plastic recycling processes, such as injection molding, extrusion molding, blow molding, thermoforming, 3D printing, plastic blending, etc.

How to Produce Recycled Plastic Pellets?

Plastic granules are indispensable in various recycling and manufacturing industries. If you want to produce plastic granules efficiently and quickly, you need a high-quality plastic granulator. As a plastic recycling specialist, Shuliy provides various plastic recycling machines, including all kinds of plastic pelletizers for different production needs.

The pelletizing process involves melting, extruding, shaping, cooling, and cutting. If you want to know more about the specific pelletizing processes, recommend viewing the following website, and please feel free to contact us. Looking forward to your news!