As a crucial component in plastic bottle recycling, the PET flakes hot washing machine utilizes electromagnetic heating to dissolve grease and other impurities attached to plastic bottles effectively. It is suitable for various plastic bottle recycling or manufacturing factories.

- Function: Wash PET flakes thoroughly

- Application: PET bottle recycling line

- Material: High-quality stainless steel

Key Features of the Shuliy PET Flakes Hot Washing Machine

- High Efficiency: The plastic scrap washing machine can quickly clean plastic bottles at high temperatures and pressures. The efficient cleaning process effectively removes dirt and bacteria left on the surface of the bottles, increasing productivity.

- Perfect Effect: The PET flakes hot washing machine utilizes high-temperature water and high pressure to thoroughly clean the surface of plastic bottle pieces of dirt and microorganisms. This cleaning method not only effectively removes stains, but also kills bacteria to ensure the hygiene and safety of the bottles.

- Customized Service: Shuliy PET flakes hot washing machines are customizable and can be adapted and personalized to meet the needs of different production lines. Feel free to contact us if you have any needs. We’re looking forward to serving you.

Specifications of the PET bottle flakes hot washing machine

The parameters of a PET plastic hot washing tank are as follows. We can also provide customized machines according to your needs.

| Height | 2m |

| Diameter | 1.3m |

| Thickness | Out wall:4mm; Bottom: 8mm |

| Material | Carton steel, and can be replaced with the materials you want |

| Power | 4KW |

| Heating Method | Mainly adopts electromagnetic heating |

| Voltage | 380V, 50Hz |

The whole structure is reasonably designed and easy to operate, which can efficiently complete the hot washing of plastic bottles.

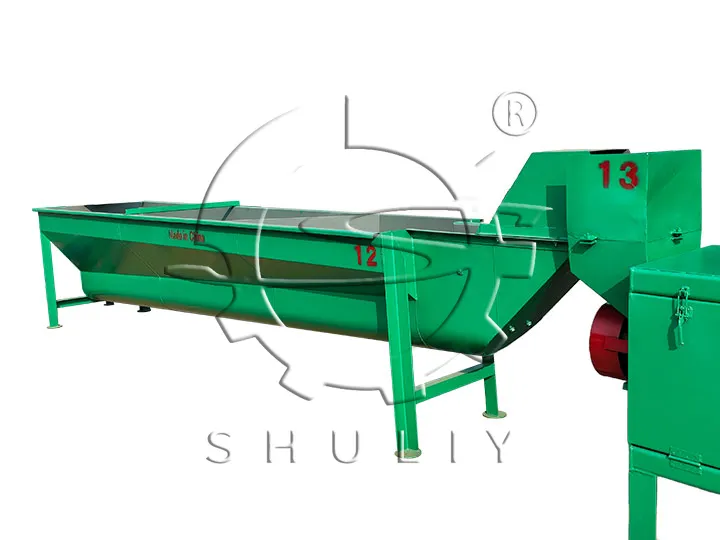

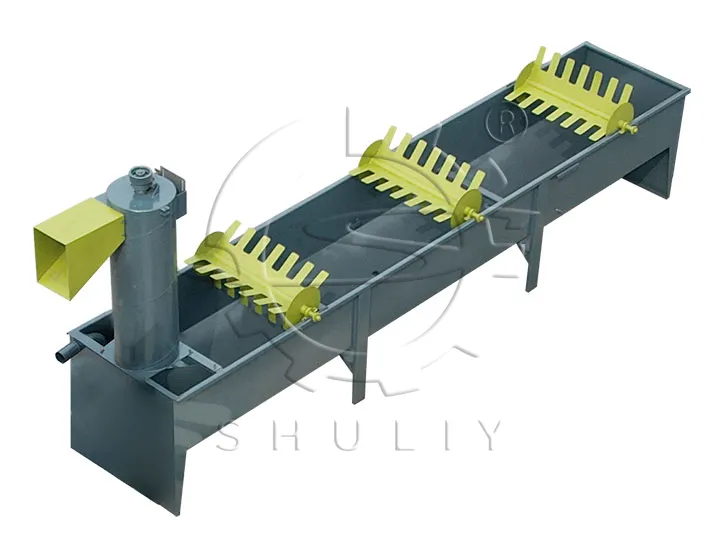

Structure Of Plastic Scrap Washing Machine

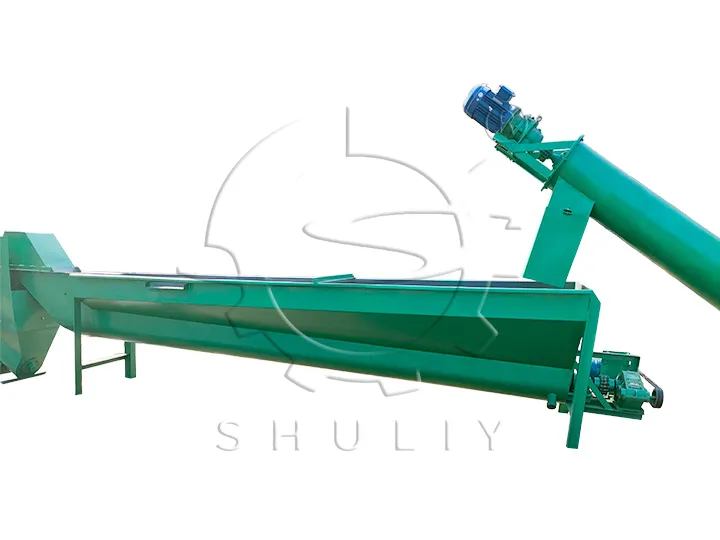

PET flakes hot washing machine usually consists of a kettle body, a heating device, a spray system, a feed inlet, and an outlet.

- Kettle body: Serves as the core component of the entire plastic scrap washing machine, and is typically fabricated from stainless steel, renowned for its excellent corrosion resistance and high-temperature tolerance.

- Heating device: An electric heater or steam heating system, provides heat energy.

- Feed inlet and outlet: Where plastic scraps enter and are discharged from the plastic hot washing machine by the conveying device.

- Spraying system: Evenly spray the high-temperature cleaning liquid on the surface of the plastic bottles through nozzles to remove the dirt and residues thoroughly.

How does the Hot Washing Machine Work?

After friction cleaning and sink float separation, residual impurities such as oil glue will still be attached to the plastic flakes. Therefore, PET hot wash tanks are required for the thorough cleaning of PET plastic fragments using a mixture of hot water and lye.

- Firstly, through electromagnetic heating, the water temperature is raised to 85-95°. Within this temperature range, the bottle remains undamaged while impurities are easily cleaned and separated.

- Then, lye is added to utilize chemical reactions to remove grease glue and other substances.

- Throughout the process, the stirring device facilitates the cleaning procedure. After stirring for 30-45 minutes, a clean finished product with a pH below 8% can be obtained.

What We Do for You About the Shipment?

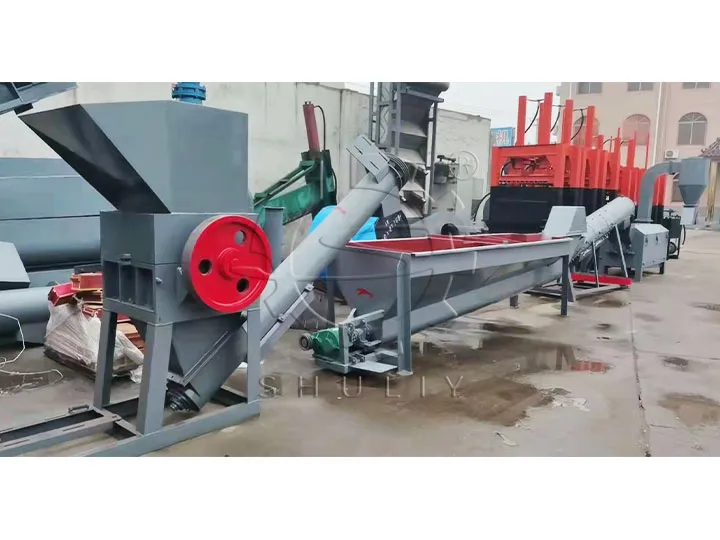

The delivery period is about 20~25 days. Before shipment, we often send the test run video to our customer, showing the machine details to ensure the machine works smoothly. After shipment by international logistics, we provide operation guides, on-site installation, and a one-year warranty. Here is a video about the entire PET bottle recycling line.

Hot Washing And Cold Washing Of PET Flakes

The cleaning process of plastic bottles is usually done in two main ways: hot washing and cold washing.

- Hot washing involves using hot water and detergent to clean plastic bottles in the PET flakes hot washing machine, where the heat helps to kill bacteria and remove stains, thus ensuring that the inside of the bottle is hygienic.

- Cold washing, on the other hand, uses room-temperature water or detergents to clean plastic bottles and is gentler than hot washing. This method is more efficient and simple and is suitable for PET bottles with light surface contamination.

PET Bottle Flakes Hot Washing Machine Price

As a professional manufacturer of plastic bottle recycling machines, our hot water washing tanks are made of advanced technology and high-quality materials to ensure that they provide excellent results and long-lasting performance in the cleaning process of plastic bottles. No matter what type of PET flakes hot washing machine you need, we can provide you with a satisfactory solution. Please feel free to contact us, and we will provide you with a detailed quotation and service according to your specific needs.

Related Plastic Recycling Machines

The hot washing machine is a crucial component in the process of PET bottle recycling. It is commonly utilized alongside a sink float separation machine and friction washing machine to effectively cleanse and recycle plastic bottles. If you’re interested, please feel free to contact us and you can get more information by clicking the following pictures.