The sink float separation tank is used to separate bottle caps, etc. impurities of different materials to ensure the cleanliness and quality of PET flakes, playing an important role in the PET bottle recycling process. It adopts advanced separation technology efficiently removing impurities. As a professional manufacturer of plastic sink float tanks, Shuliy offers a wide range of high-quality machines, welcome to Inquire.

- Function: separate the impurities from PET flakes

- Raw Material: PET flakes

- Final Product: Clean PET flakes

- Application: PET bottle recycling line

Features Of PP PE Separating Tank

- Efficient Separation: Plastic sink float tanks can efficiently separate caps from other impurities through special design and working principles. This high efficiency ensures the smooth running of the plastic bottle washing line and increases production efficiency.

- Adjustable: Sink float tanks’ plastic scrap separations are often adjustable to suit different cap sizes or job requirements. This flexibility allows the equipment to be adapted to different cap sizes, thus increasing its scope of application and flexibility.

- Customizable: Depending on the specific needs of the customer, the sink float plastic separation can be custom-designed to meet specific production requirements or processes. Customized design can make the plastic float sink tank better adapt to the specific production environment and process requirements, improve production efficiency, and reduce production costs.

Parameters Of Plastic Chips Washing Machine

The hot-selling Shuliy SL-500 plastic chips washing machine is a multi-functional machine with customizable dimensions. It is widely used in plastic bottle recycling plants and other applications, providing users with efficient and convenient bottle-washing solutions.

| Power | 3KW |

| Length | 5,10,15m |

| Material | High-quality stainless steel |

| Application | wash PET plastic bottles and separate impurities |

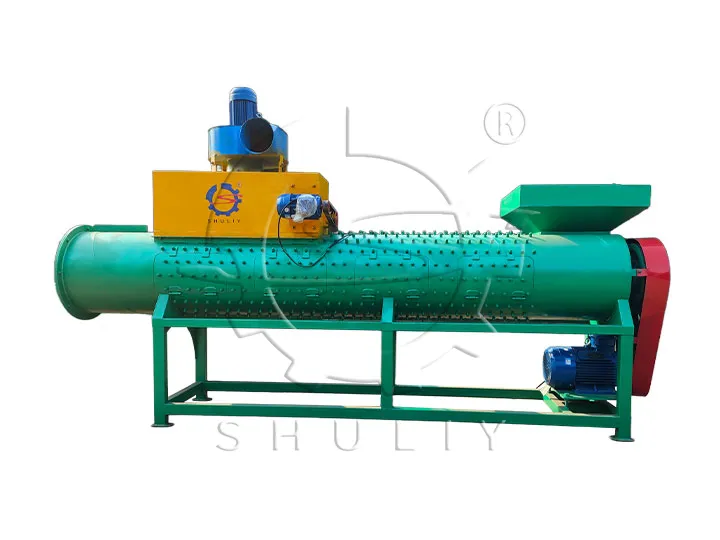

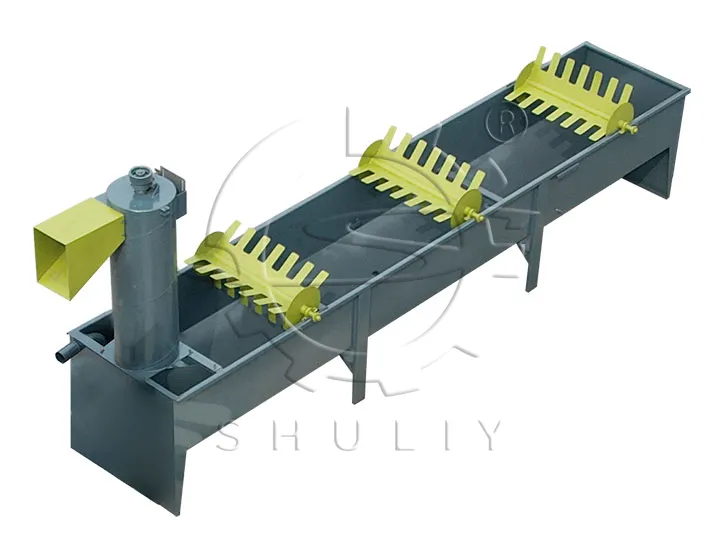

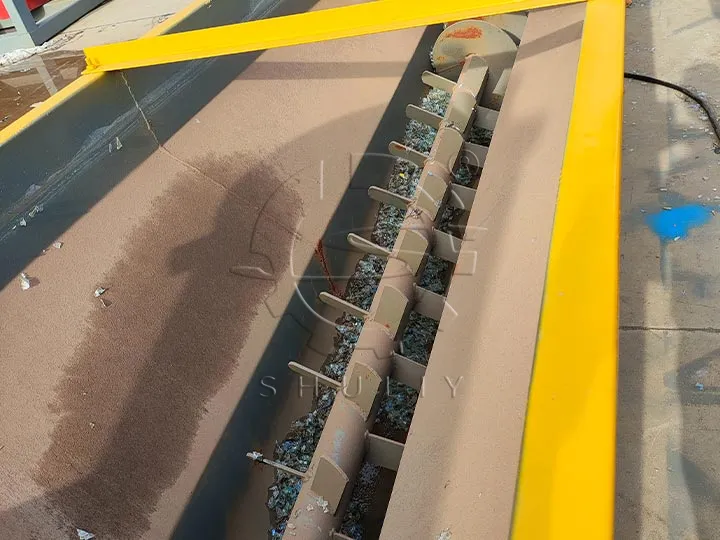

Sink Float Separation Tank Structure

The plastic sink float separation tank adopts sophisticated designs to ensure production efficiency, consisting of a tank body, a feed inlet, an outlet, an agitation mechanism, an overflow port, a drainage system, etc. All these structures work together to boost the PET bottle flake washing and impurities removal process.

- Tank Body: Constructed from high-quality stainless steel, features durability and resists corrosion.

- Feed Inlet: Located at the tank top, allowing PET flakes to enter the machine.

- Outlet: Located at the bottom of the machine, where cleaned PET flakes are discharged.

- Agitation Mechanism: Tooth plates rotate rapidly, pushing water waves and waves to clean PET materials. It can also effectively keep the materials in suspension to improve the separation process.

- Overflow Port: Located at the upper end of the tank, it controls the liquid height and ensures the separation effect.

- Drainage System: Ensure that after the separation process, the liquid in the tank can be drained smoothly, making it easy to clean and maintain.

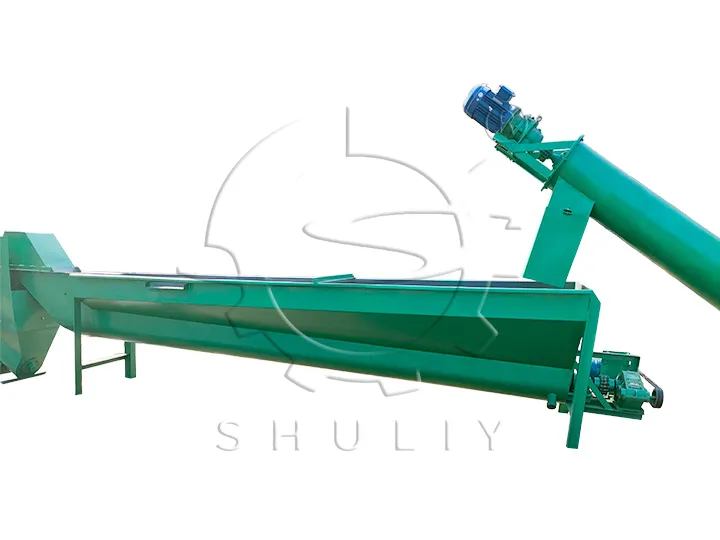

Working Principle Of Plastic Sink Float Separation Tank

The sink float separation tank utilizes the difference in density of different substances in the liquid to achieve effective separation of materials such as bottle caps and labels from PET bottle flakes.

- In the rinsing tank, PET bottle flakes and other denser objects will sink to the bottom of the pool, while bottle caps, labels, and other materials have a lower density, allowing them to float on the water surface.

- The lower-density materials float on the water’s surface and then outflow through the overflow port on top of the tank body.

- The PET flakes are discharged from the outlet.

Through these operations, the plastic float sink tank can effectively separate materials such as bottle caps from PET bottle flakes, realizing a clean treatment for PET bottle flakes.

Preparation for Shipment

Before shipment, we often send the test run video to our customer to ensure the machine working smoothly. One of the videos is as follows. You can see how the plastic rinsing tank works. To well satisfy customer’s needs, we can also provide customizable service. Moreover, we promise that we provide a one-year warranty and on-site installation. If you’re interested, welcome to inquire.

Plastic Float Sink Tank Price

When you are looking for an efficient way to separate PET bottle flakes from PP PE impurities and thoroughly clean bottle flakes, our sink float separation tank is your best choice. As a professional manufacturer of plastic recycling machines, Shuliy uses advanced technology to ensure that bottle flakes are thoroughly cleaned. You are welcome to contact us for detailed pricing information, we will provide a competitive quote and add efficiency and convenience to your cleaning process.

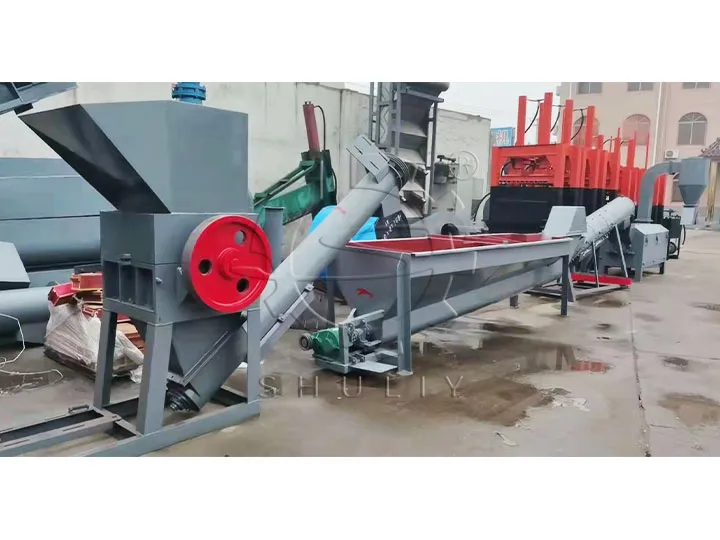

Related PET Bottle Recycling Machines

The sink float separation tank is usually used in conjunction with plastic label removing machines, plastic crushers, plastic dryers, hot washing tanks, etc. to form a complete plastic bottle recycling line. Shuliy can provide customized solutions according to customers’ needs to improve the efficiency of plastic recycling lines. If you’re interested, you can get more information by clicking the following pictures and please feel free to contact us.