Shuliy’s plastic film recycling plants are suitable for all sizes of factories to recycle various plastic films and can be customized to satisfy customer’s production needs.

- Capacity: 100~500kg/h

- Raw Materials: plastic films, such as woven bags, raffia, etc.

- Final Products: Renewable plastic granules

- Applicable objects: All sizes of plastic film recyclers and manufacturers

Key Features of the Shuliy Plastic Film Recycling Line

- Widely Application:

- Handle various kinds of plastic films

- Be able to apply in all sizes of factories

- High-Efficiency:

- Efficiently recycle plastic films 100~500kg/h

- Can promise constant production without problems.

- Considerate Service:

- Detailed consultation service

- Factory layout design

- A one-year warranty, on-site installation, and operation guides.

Process Various Raw Materials into You Want

Raw Materials

- Post-consumer Materials: PP, PE, PVC, BOPP, etc., such as waste woven bags, agricultural films, cling films, PP raffia grass, cement bags, plastic packaging films, etc.

- Post-industry Materials: Scraps produced during the new plastic film production process.

Read: Stretch Film Differences with Shrink Film and Recycling Process

Final Products

- The plastic film recycling plant puts waste plastic films through sophisticated treatment processes and eventually converts them into plastic pellets.

- These recycled pellets have a variety of uses and can be utilized in various types of processes, such as blow molding, injection molding, thermoforming, etc.

How to Realize the High-Efficiency Recycling Process?

The workflow of a plastic film recycling plant typically consists of the following steps:

Step 1: Collecting&Sorting

Collect materials such as agricultural films, packaging bags, and woven bags made of PP, PE, PVC, etc. Sort them separately to ensure product purity.

Step 2: Cushing Films into Smaller Pieces

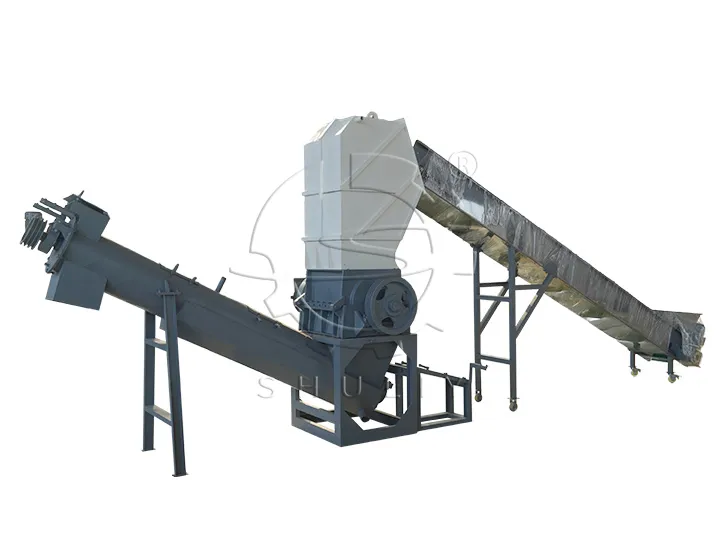

Plastic Film Shredder

Plastic film crushing is the first process of the whole plastic recycling line. The plastic film crusher can efficiently crush various types of plastic films to ensure that the subsequent cleaning and processing can be carried out smoothly. The resulting plastic films are around 20-26mm.

Step 3: Washing Plastic Films Fragments

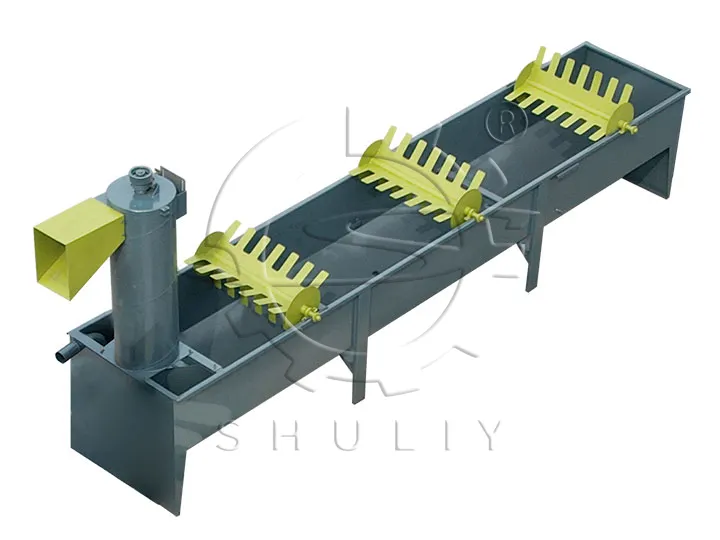

Plastic Film Washing Machine

The plastic film washing machine is used to clean the plastic films by efficiently removing the dirt and impurities attached to the surface. And ensure that the quality of the recycled plastic produced meets the standards. At the same time, the screw transfer machine pushes the clean plastic films to the next machine.

Step 4: Pelletizing Film Pieces into granules

Plastic Pelletizing Machine

After crushing, washing, and drying, the plastic film is fed into a plastic granulator for further processing. This pelletizing machine heats, melts, and forms the plastic film into long strips through the mold head.

Cooling Tank

The cooling tank rapidly cools the plastic strips extruded from the pelletizer to ambient temperature, ensuring that the shape and size of the plastic are stabilized. The cooling tank adopts a professional cooling system, which can effectively reduce the temperature of the pellets and ensure the quality of the products.

Plastic Cutter Machine

The plastic cutter machine can accurately cut the cooled plastic strips through the high-precision cutting system, to make them reach the particle size and shape requirements demanded by customers, and meet the needs of different customers.

Step 5: Drying&Storage

Plastic Film Dryer

The cleaned plastic film needs to be dried to ensure that the subsequent granulation process can be carried out smoothly. Vertical plastic dryer adopts unique vertical designs, which can make full use of space and improve production efficiency.

Storage Bin

As a temporary storage place for plastic pellets, the storage bin can provide a clean and dry storage environment to ensure the quality of the plastic pellets remains unaffected. Its large-capacity design and convenient operation make it able to meet the needs of different-scale production.

Pre-shipment Demo of Plastic Film Recycling Plant

To ensure the machine’s proper functioning, we will provide customers with a video inspection before shipment to confirm its condition. The following video is an example.

Plastic Granulator Machine Sent To Saudi Arabia

Recently a customer from Saudi Arabia operated a plastic film recycling plant that faced the challenge of disposing of waste plastic film. Due to the large amount of waste plastic film, traditional treatment methods were inefficient and costly. After communicating and cooperating with our company, they decided to purchase the Shuliy plastic recycling granulator machine. Through our equipment, they successfully transformed a large amount of plastic film into plastic pellets, solved the problem of waste plastic film disposal, and realized a win-win situation regarding economic and environmental benefits.

Professional Plastic Film Recycling Plant Manufacturer

Shuliy is a professional plastic film recycling plant manufacturer, dedicated to providing customers with a high-quality plastic film recycling plant. With advanced technology and rich experience, we can custom design and manufacture plastic pelletizing lines of various specifications and requirements to meet customers’ different production needs. If you also want to upgrade your existing equipment or start your plastic recycling business, feel free to contact us for a personalized solution, and we will serve you with the most patient and professional attitude.

Plastic Granulating Machine Price

Are you curious about the price of a plastic film pelletizing line? Shuliy plastic film recycling plants are available in a variety of configurations and sizes to meet different customer needs.

The price depends on factors such as production capacity, equipment quality, and technical parameters. We are committed to providing customers with cost-effective solutions to ensure equipment quality and production efficiency.

Customers are welcome to contact us at any time. We will provide detailed quotations and professional advice according to your specific needs.