The plastic recycling washing machine is used for cleaning and treating all kinds of plastic films, usually used in the plastic film recycling plant. These plastic film washing machines effectively remove dirt, residue, and chemicals from the surface of plastic film, leaving it in a clean state for the next step of recycling and pelletizing. As a professional plastic recycling machine manufacturer, Shuliy offers high-quality plastic film washing machines, please feel free to contact us for details.

- Capacity: 100~500kg/h

- Raw Materials: PP PE films, such as woven bags, agricultural films, packaging bags, etc.

- Function: washing plastic films deeply.

Advantages Of PP PE Plastic Washing Tank

- Plastic recycling washing machines are usually equipped with an adjustable gear system, which allows you to adjust the angle and speed of the gears according to different types of plastic films to ensure better cleaning results. You can also feel free to contact us for a more suitable plastic recycling solution for you.

- Plastic washing machines utilize a specially designed cleaning mechanism that effectively removes dirt, residue, and contaminants from the film surface. This ensures that the surface of the cleaned plastic film is clean and contributes to the quality of the recycled pellets.

- This plastic film washing machine is typically constructed using corrosion- and abrasion-resistant materials., such as stainless steel or special plastic materials. This gives it good durability and can withstand long-term use and intense cleaning operations without being easily damaged or rusted.

- Plastic recycling washing machines are equipped with a high degree of automation, reducing manual labor and improving plastic washing efficiency.

Parameters Of Waste Plastic Film Washing Machine

The SL-150 model is a popular plastic recycling washing machine with a tank length of between 15 and 20 meters, equipped with 10 rotating wheels with a distance of 1.5 to 2 meters between each two wheels.

This plastic rinsing tank is suitable for plastic pelletizing lines from 100 to 500 kg/h, providing standard cleaning and separation functions. However, for higher output requirements, up to 600-1000 kg/h production, it is recommended to choose a longer plastic rinsing tank, such as a 30-meter length, to ensure efficient operation and production.

| Name | plastic scrap washing machine |

| Length | 15~20m |

| wheels quantuty | 10 |

| capacity | 100~500kg/h |

| Function | washing plastic films |

| Raw Materials | plastic films made of PP, PE, PVC, etc. |

| Final Product | Plastic films scraps |

| Warranty | One year |

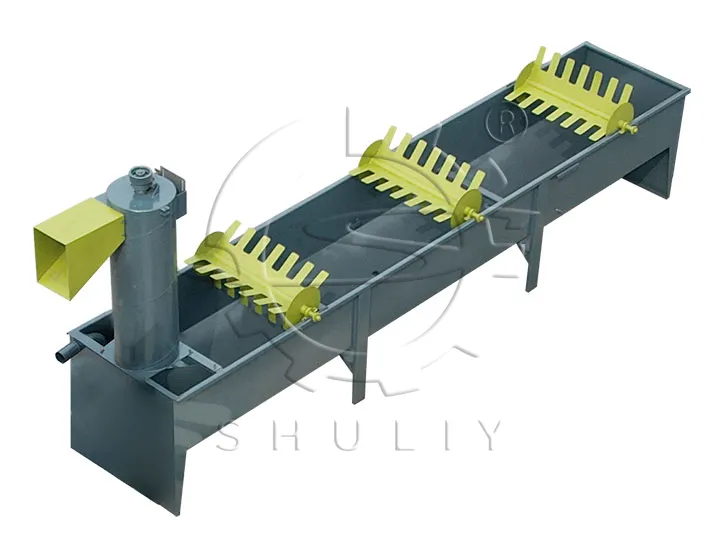

Plastic Recycling Washing Machine Structure

A plastic recycling washing machine is a piece of equipment used to clean plastic film, usually mainly consisting of a rinsing tank, a gear system, an inlet and outlet system, and a drainage system.

- The rinse tank is typically made of corrosion-resistant stainless steel and has a certain depth and width to accommodate the plastic film to be cleaned.

- The gear system is used to drive the water or cleaning solution in the plastic washing machine, creating a flow through the rotating gears to ensure thorough cleaning of dirt and residue from the surface of the plastic film. This design allows the plastic film washing tank to clean large quantities of plastic film efficiently and to ensure good cleaning results.

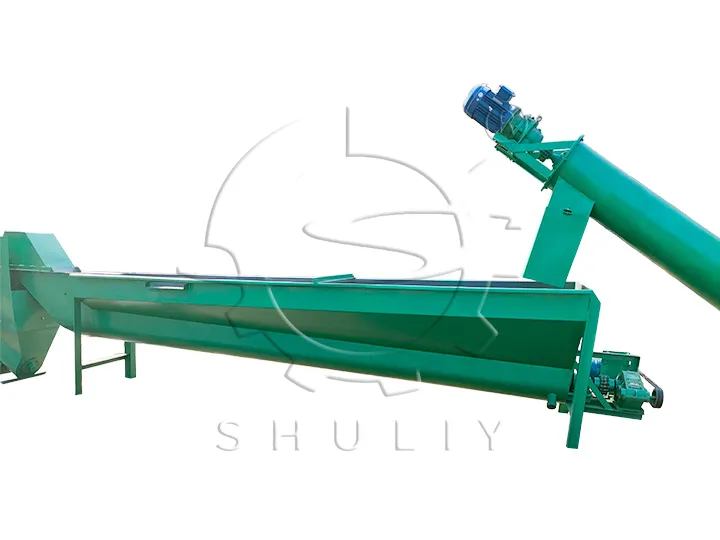

- The inlet system is located at the top of the plastic rinsing tank, which allows plastic film flakes conveyed to the tank conveniently. The outlet system is situated opposite the tank to remove cleaned flakes to the plastic pelletizer machine for subsequent granulation.

- A drainage system typically includes drainage valves and a sludge removal mechanism to remove dirty water and sludge. The drainage valves are positioned at the bottom of the tank. The suction system collects and removes settled contaminants.

Working Principle Of Plastic Washing Machine

The plastic recycling washing machine is a device for cleaning plastic film, and its working principle is based on the toothed plate’s push and the water flow’s agitation. When the plastic film enters the plastic washing machine through the inlet system, the toothed plate starts to push the plastic pieces to move from one end of the plastic rinsing tank to the other, so the plastic film continues to roll and turn over in the water.

At the same time, the water continuously agitates the plastic film, thoroughly washing away the dirt and impurities attached to the surface. This combined action ensures that the plastic film receives a complete and thorough cleaning in the plastic rinsing tank, providing clean material for subsequent processing or reuse. Finally, the dirty water and settled contaminants are removed.

Service Of Plastic Recycling Washing Machine

- Pre-sales: We provide professional consultation and personalized customization services to help customers select the most suitable machines.

- On-sales: During the purchase, we are available to answer any questions and assist customers with their orders as soon as possible. We offer detailed technical information on PET bottle washers. Besides, we ensure timely delivery of machines and offer various payment methods to meet different customer preferences.

- After-sales: We promise a one-year warranty at no extra cost and on-site installation service if you need it. What’s more, if there are some bad parts of the PET bottle crusher, it can be re-sent by express delivery.

Related Plastic Film Recycling Machines

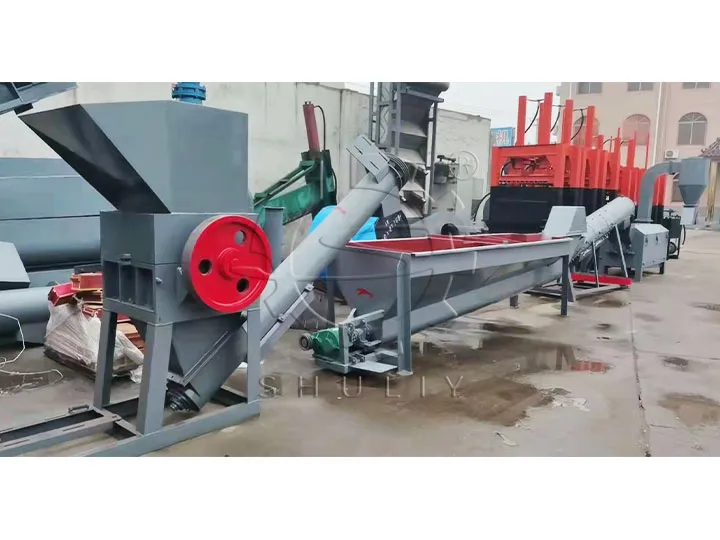

Plastic recycling washing machines are indispensable plastic pelletizing line equipment, usually used together with a plastic film crusher, plastic dryer, and plastic pelletizer to produce high-quality recycled pellets. The pictures of pp pe recycling machines are as follows. If you’re interested, please get in touch.

Plastic Film Washer Price

Plastic recycling washing machine prices vary by model, size, material, and features. If you want to know the specific price and product details, please contact Shuliy. As a professional plastic recycling equipment manufacturer, we provide high-quality plastic washing machines and other plastic recycling equipment. You can contact us through the official website or contact us, there will be a sales team to provide you with detailed information and quotation.