Plastic baling machines are specially designed to compress waste plastics into blocks for easier transportation and disposal. It effectively reduces the amount of space taken up during transportation and lowers recycling costs by compressing plastic into compact blocks during the recycling process of plastic bottles and plastic film.

Plastic baling machine applications

Hydraulic plastic baling machine is widely used in plastic bottle recycling plants and plastic pelletizing plants for compressing various types of waste plastics, including plastic bottles, plastic films, HDPE bottles, cans, clothes, woven bags, waste cartons, oil drums and so on. It compresses these waste plastics into compact blocks for easy storage and transportation, facilitating the subsequent recycling process.

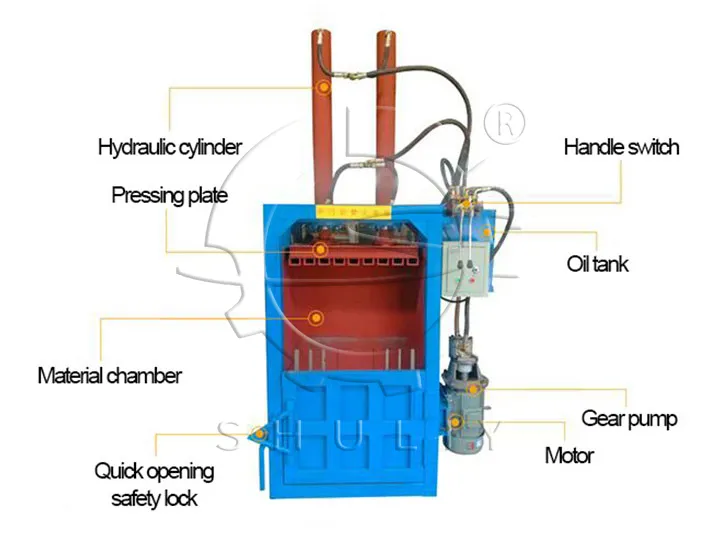

Hydraulic plastic baling machine structure

Baler machine for plastic is a commonly used packaging equipment, mainly consisting of hydraulic cylinder, pressure plate, handle switch, oil tank, material room, quick open safety lock, gear pump and motor and other components.

The hydraulic cylinder compacts the plastic through the platen, the handle switch controls the start and stop of the machine, the fuel tank stores the hydraulic oil to provide power, the material chamber is used to place the material to be packaged, the quick-open safety lock ensures safe operation, and the gear pump and electric motor provide power support. Together, these components enable the hydraulic plastic baling machine to perform its packaging tasks efficiently and consistently.

Workflow of baler machine for plastic

The workflow of a baler machine for plastic typically consists of several key steps. First, the waste plastic is placed into the baling chamber. The plastic baling machine is then activated, utilizing a hydraulic pressure system to compact the material to ensure that the baled material maintains a solid shape and structure.

Next, the hydraulic plastic baling machine automatically performs strapping, using rope or plastic straps to hold the materials together to prevent scattering and damage. Finally, once the strapping is complete, the plastic baler ejects the baled material so that it can be easily handled or stored. The entire workflow is usually performed under automated control to improve efficiency and accuracy.

Two types of plastic baler

Horizontal plastic baler

Horizontal balers typically have a large baling force and capacity to handle large materials such as plastic bottles and containers. They usually operate horizontally, feeding the plastic products horizontally into the baling chamber for baling, followed by compression and sealing. This design saves space and therefore plays an important role in plastic bottle recycling plants.

Vertical plastic baler

Vertical balers are usually more compact and have a smaller footprint. They typically operate vertically, feeding plastic film or other smaller plastic products vertically into the baling chamber for baling. Vertical balers typically have faster baling speeds and a higher degree of automation, making them suitable for handling plastic film pelletizing lines.

Plastic baler price

Welcome to our plastic baling machines! We offer a wide range of models and configurations for packaging operations of varying sizes and needs. No matter what materials you want to handle, we have a solution for you. Please feel free to contact us and we will provide you with detailed product information and a quote based on your specific requirements.