With its lightweight and insulating properties, PET is widely used, but these materials are difficult to break down in nature. So the PET recycling process is significant, which can not only protect the environment but also reduce resource waste.

Physical Recovery

Physical PET recycling process methods are the easiest to implement. There are two physical recycling methods for PET polyester: The first method involves cutting the material first and then separating impurities. At the same time, the second method involves separating the material using a line and then performing the recovery step.

PET waste mainly comes from drink bottles, packaging materials, etc. Recycling systems usually set up special recycling bins or recycling stations to facilitate consumers’ classification and disposal. After collection, the waste PET materials are classified by manual or mechanical to make the surface.

First Method:

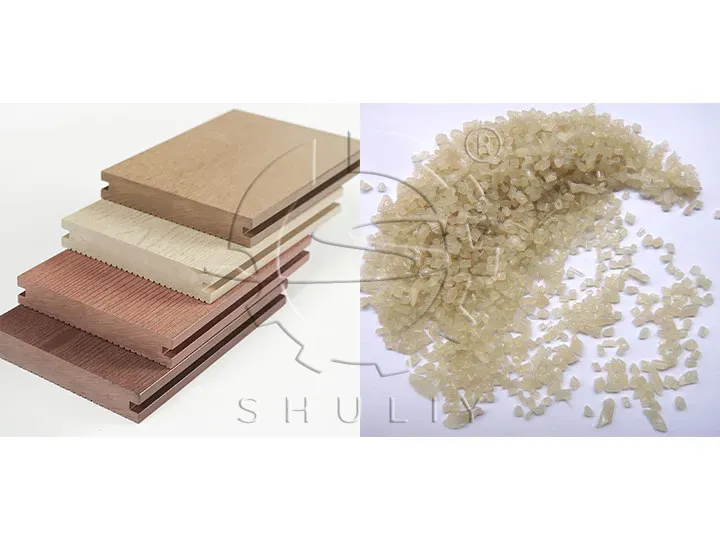

- After classification, large PET materials are crushed into small pieces(10-20mm) by a plastic shredder for subsequent recycling.

- At the time, these PET flakes are mixed with some residual stains, glue, and other impurities.

- Separate the impurities and then wash and pelletize through multiple processes.

Second Method:

By mechanical separation methods, impurities are first separated, then washed, crushed, and pelletized. Both methods are common ways to effectively recycle PET bottle flakes.

The PET Recycling Processes Used

- Hot Washing: Hot washing plays a crucial role in the PET recycling process as it involves cleaning the bottle flakes using hot water at temperatures exceeding 80°C. This method effectively eliminates oil, adhesive, and other organic substances from the surface of the bottle flakes, directly impacting the purity and quality of the regenerated PET.

- Centrifugal Separation: Centrifugal separation utilizes the centrifugal force generated by high-speed rotation to separate materials of different densities. Materials with higher density move outward under the action of centrifugal force, while impurities with lower density remain on the inside or are eliminated. This method is often used for the separation of fine particles to ensure the purity of the final product.

- Flotation Method: The flotation method separates materials and impurities based on their density differences. In water or other media, materials with higher density will sink, while impurities with lower density will float on the surface. In the PET recycling process, density separation is often used to remove impurities with lower density, such as caps, labels, and other plastic materials, from PET bottle flakes.

Chemical Recovery Process

In addition to physical recycling, PET can also be chemically depolymerized and broken down for re-synthesis into rPET. The methods generally fall into the following categories: hydrolysis, alcoholysis, aminolysis, and thermal depolymerization.

Food-grade Recycling Process

For food-grade applications, the PET recycling process requires higher purity standards. The food-grade recycling process typically includes multiple washing, vacuum degassing, and solid-phase polymerization steps to remove any potential contaminants and ensure that the regenerated PET meets food safety standards.

Conclusion

There are many PET recycling processes available, and you can choose the one that best suits your needs. If you are interested, please feel free to contact us, and Shuliy will provide you with the most sincere advice.