HDPE is a thermoplastic polymer that has excellent chemical resistance, wear resistance, etc. Thus it is widely used, with high utility and recycling value. The steps of how is HDPE recycled involve collecting, sorting, crushing, washing, pelletizing, drying, etc. And the specifics are as follows:

Details About How is HDPE Recycled

Where can I collect HDPE plastic?

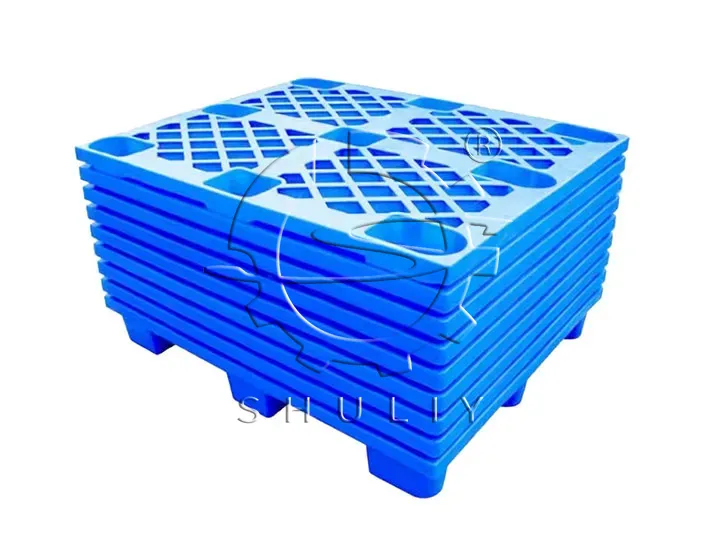

HDPE is a common type of plastic known for its resistance to chemicals, corrosion, and high density, and it is easily collected in the following areas:

- Milk bottles

- Containers for shampoo and other cosmetics

- Boxes, pallets, and other packaging materials

- Gas pipes and drainage pipes

- IBC containers and wheeled trashcans

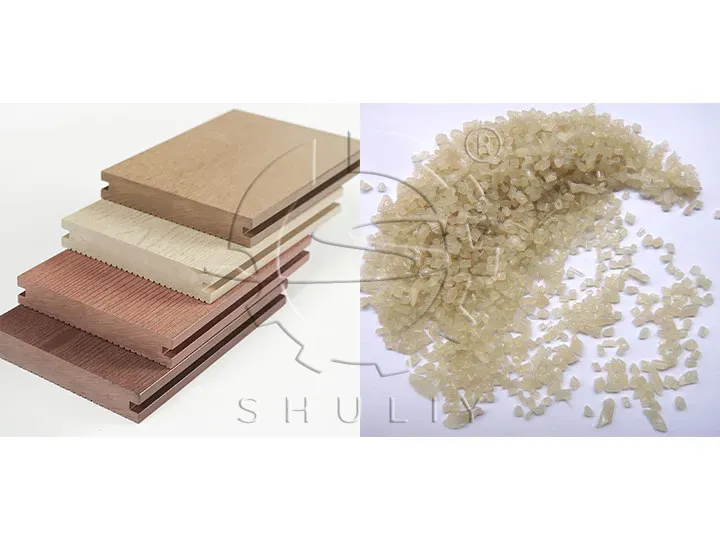

Sorting and Crushing

After gathering HDPE plastics, the initial recycling process involves sorting the materials by thickness and then crushing them. There are two types of plastic shredders specifically designed to process different HDPE materials based on their thickness. The function of the shredder is to cut large pieces of HDPE material into smaller pieces for subsequent processing.

Washing HDPE Materials

The HDPE is deeply washed using a washing tank to remove stains, oils, labels, and other impurities that may be adhering to its surface, ensuring the quality and purity of the final product. During the washing process, you can add cleaning agents as needed for rinsing. In addition, you can adjust the number of washing tanks based on your production needs and facility space.

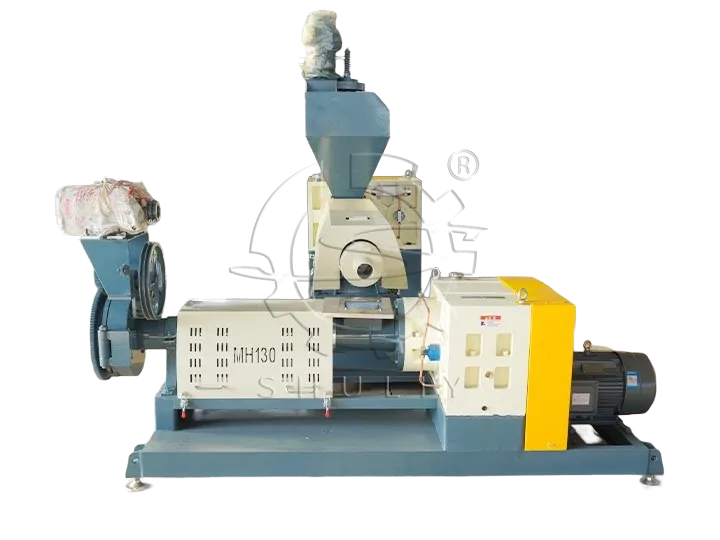

Pelletizing in HDPE Recycling Process

An important step in recycling HDPE! Through melting, shaping, cooling, and cutting, the washed plastic fragments are transformed into pellets of the required size. In these processes, HDPE plastic scraps are melted by heating devices by heating devices and then extruded by die heads into the shape of dense long strips. Finally, the plastic pellet cutting machine cut the plastics into plastic pellets.

Additionally, other additives can be added during granulation to modify the particles and increase the value of HDPE recycled particles.

Drying and Storage

After the above recycling steps, the plastic drying machine dewaters plastic pellets rapidly. Then, the high-quality products can be stored for reproduction.

What can Shuliy do for You?

As a plastic recycling specialist, Shuliy provides professional recycling machines for HDPE. With the technical assistance of Shuliy machinery, you don’t worry about how is HDPE recycled.

- Made of 60Si2Mn, our blades of plastic shredder are durable enough and resistant to corrosion.

- Equipped with automatic systems, our HDPE recycling machines are simple to operate and reduce manual costs.

- We offer customized machines according to your production needs.

- Whether before or after the sale, if you have any questions about the machine, please feel free to consult us at any time. In addition, we provide technical support, including installation tutorials, a one-year warranty period, and even on-site installation.

If you’re interested, please feel free to contact us. Looking forward to your news!