La machine de découpe de chutes de tissu est un outil industriel qui déchire les déchets de tissu en segments de fibres courts et uniformes (5–300 mm). Elle constitue une étape cruciale dans le recyclage des tissus, améliorant l'efficacité et rendant les matériaux adaptés à un traitement ultérieur. Également connue sous le nom de machine à couper les fibres ou de coupeur de textile, elle peut traiter une grande variété de tissus souples, flexibles et mélangés.

Quels matériaux bruts peuvent être traités ?

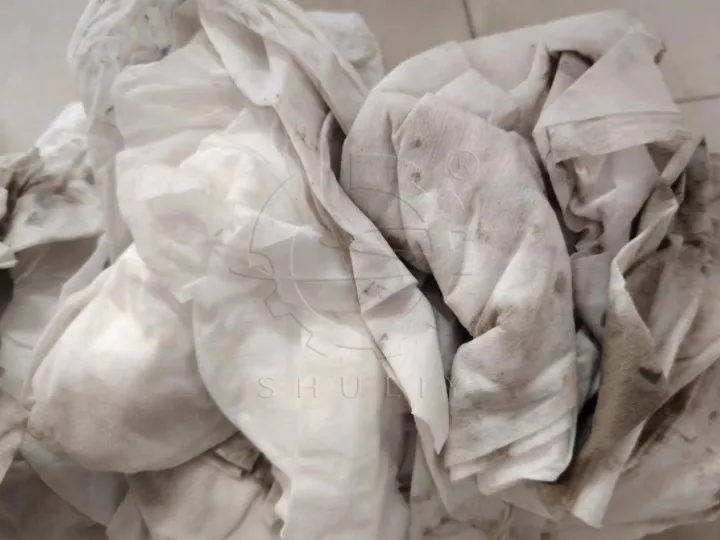

La machine prend en charge une large gamme de types de tissus, y compris :

- Chiffons en coton et déchets de fil

- Déchets de polyester et de nylon

- Tissu en denim et jeans

- Tissu en fibres mélangées

- Chutes de textile provenant des usines de vêtements

- Rouleaux et sacs non tissés

Produits finaux et applications

Après la découpe, la sortie de fibres courtes peut être utilisée pour :

- Remplissage (coussins, oreillers, jouets, canapés)

- Granulation et pelletisation de fibres

- Matériaux d'isolation phonique/thermique

- Renforcement dans les produits en plastique ou en caoutchouc

- Matières premières pour le fil recyclé

Avantages de la machine de découpe de tissus de récupération de Shuliy

✅ Haute Productivité : Traitez jusqu'à 5000 kg/h, selon le matériau et les tailles de coupe textile.

✅ Taille de Découpe Personnalisée : Longueur de sortie ajustable pour répondre à des besoins divers (5-300 mm)

✅ Structure Durable : Cadre en acier robuste et lames résistantes à l'usure

✅ Facile à Utiliser : Changement de lame facile, entretien simple

✅ Agencement Compact : Convient à la fois pour les grandes usines et les petits ateliers

✅ Efficace Énergétiquement : Consommation d'énergie optimisée pour un faible coût d'exploitation

Comment fonctionne la machine de découpe de fibres textiles ?

La machine utilise des lames en spirale rotatives et une plaque de coupe stationnaire pour couper les déchets textiles entrants en segments de fibres courtes. Elle dispose d'une chambre de coupe fermée avec alimentation continue et décharge automatique.

Aperçu Technique :

- Mécanisme de coupe : Coupeur rotatif en spirale

- Méthode d'alimentation : Manuelle ou convoyeur à bande en option

- Matériau de la lame : Acier allié durci

- Taille de coupe : Réglable entre 5-300 mm

- Protection du moteur : protection contre les surcharges et la surchauffe incluse

Ce design minimise l'enchevêtrement des fibres et garantit un fonctionnement fluide et sans obstruction, même lors du traitement de tissus doux, duveteux ou à haute résilience.

Données techniques de la machine de découpe de déchets de coton

Voici quelques paramètres des machines de découpe de déchets textiles les plus vendues. Si vous avez d'autres besoins, nous pouvons vous fournir des coupeurs personnalisés.

| Modèle | 500 B | 800 C | 1200 B | 1600 B | 2400 B |

| Puissance (KW) | 5.5+1.5 | 7.5+1.5 | 1.5+2.2 | 18.5+3.0 | 22+3.0 |

| Capacité (kg/h) | 300-500 | 500-800 | 800-1200 | 1000-3000 | 2000-5000 |

| Taille de coupe (mm) | 5-150 | 5-150 | 5-150 | 5-300 | 10-300 |

| Épaisseur de coupe (mm) | 20 | 30-50 | 30-80 | 30-150 | 30-200 |

L'industrie florissante du recyclage des fibres

Alors que les déchets textiles mondiaux augmentent, l'industrie du recyclage des fibres prend de l'ampleur. De plus en plus de fabricants transforment les tissus jetés en produits rentables. Avec une machine de découpe de tissus usagés fiable, les entreprises peuvent transformer les chutes de tissu en fibres réutilisables, débloquant ainsi des avantages économiques et environnementaux.

Cette industrie en pleine croissance offre des rendements attrayants : les usines de recyclage bien équipées peuvent bénéficier de marges bénéficiaires brutes de 25 à 40 % en transformant les déchets textiles en matériaux de rembourrage, panneaux isolants, et plus encore.

Cas d'application dans le monde entier

Pourquoi choisir la machine de découpe de tissus de coton de Shuliy ?

Avec plus de 15 ans d'expérience, Shuliy est un fabricant de confiance de machines de découpe de tissus pour le recyclage. Nous offrons :

- Performance fiable et certification CE

- Prix compétitifs avec ventes directes d'usine

- Livraison mondiale et support technique en ligne

- Personnalisation de machine sur mesure pour vos matériaux

Si vous êtes intéressé par le recyclage de fibres, veuillez nous contacter pour des solutions personnalisées !