タイヤリサイクルの成長分野において、タイヤカッター機械はもはやオプションではなく、必需品です。シュリイは、異なるレベルのタイヤ処理ニーズに応えるために設計された2つの独自のモデルの油圧タイヤカッター機械を販売しています。コンパクトなトラックタイヤから巨大なOTRタイヤまで、私たちの機械は比類のない多様性、精度、パワーを提供します。

これらの機械が廃タイヤからどのようにより大きな価値を引き出し、現代のタイヤリサイクルワークフローにどのように適合するかを探ってみましょう。

廃タイヤカッターはどのような問題を解決しますか?

タイヤはかさばり、頑丈で、強い圧力に耐えるように作られています。しかし、リサイクルの際には、この耐久性が課題となります。手作業で切断するのは時間がかかり、危険です。タイヤをそのままシュレッダーに投入するのはさらに悪化します—過負荷、均一でない摩耗、そして生産性の低下を引き起こします。

ここで登場するのが販売用の油圧タイヤカッターマシンです:これは問題を文字通り、より管理しやすく均一な塊に分解します。

2つのタイヤカッティングマシン、2つの役割

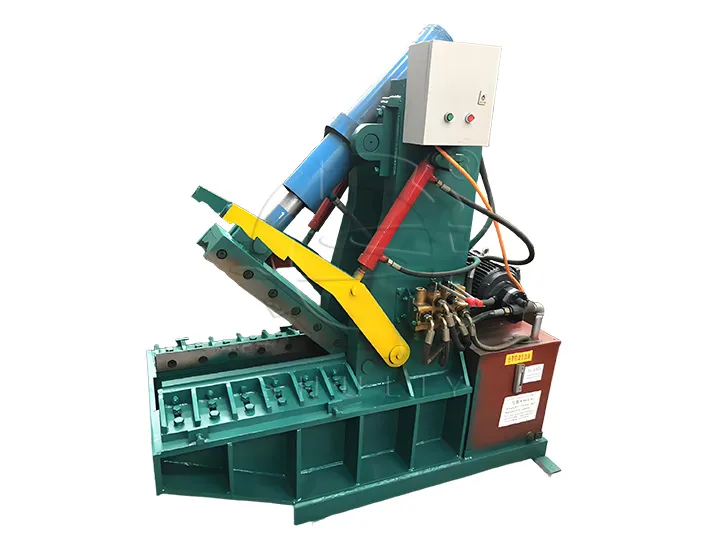

トラックタイヤ用油圧タイヤカッティングマシン

ユースケース: トラック、バス、ローダー用の中小サイズのタイヤ(900~1200mm)。このコンパクトでパワフルなゴムタイヤカッターは、標準サイズのタイヤを900mm以下のブロックに加工するように設計されており、シュレッダーへの投入や転売目的での保管に最適です。

主要性能仕様:

- 力7.5 kW

- 切断能力60タイヤ/時

- フットプリント1.7*0.8*1.85 m

- ブレードタイプCr12MoV合金鋼

- 互換タイヤサイズ: 900–1200 mm(ビードワイヤーなし)

- 重さ: 1400 kg

🔗 タイヤビードワイヤーリムーバーの後に使用され、デビードされたタイヤを安全に切断します。

ハイライト:

- 分散型またはモバイルリサイクルセットアップに最適です。

- フットペダルまたはプッシュボタン制御

- エネルギー効率の良い油圧システム

- 最小限のメンテナンス、高出力

巨大なオフロードタイヤ用のOTR廃タイヤカッター

ユースケース: 直径4メートルまでの特大エンジニアリングタイヤ(例:鉱山用ダンプトラック、重機)。このモデルは強力です。ビードワイヤー除去後、1トンを超えるタイヤを強力な油圧と多段切断アームで処理できるように作られています。

性能仕様:

- 力7.5 kW

- 切断サイクル2ストローク/分

- 寸法3.13*1.65*2.7 m

- 刃の材質Cr12MoV

- タイヤ範囲1400–4000 mm(ビードなし)

- 機械の重量7200 kg

🔗 OTRビードワイヤーエクストラクターに続くように設計されており、2段階の切断ソリューションを形成します。

ハイライト:

- 中央集権型または産業用タイヤリサイクルハブに最適です。

- 鉱業および軍用グレードのタイヤを扱います

- 強力なフレームサポートによる優れた切断制御。

タイヤカッター機械はどのように機能しますか?

両方の機械は油圧切断メカニズムで動作します。

- モーター駆動の油圧ポンプが切断アーム/ブレードを前方に押し出します

- ブレードがタイヤ本体をきれいに切り裂きます

- オペレーターは制御パネルやフットペダルを使用してプロセスをロードし、トリガーします

- 安全のために、緊急停止と圧力制御バルブが統合されています

火花なし。煙なし。滑らかで機械的な力だけです。

タイヤカッターの利点

| 特徴 | 利点 |

|---|---|

| 油圧駆動 | 強力で静か、信頼性の高い操作 |

| モジュラー設計 | 既存のラインに簡単に統合可能 |

| 鋭い産業用ブレード | 長寿命、低摩耗、精密カット |

| 広い互換性 | 900mmから4000mmのタイヤに対応 |

| 低メンテナンス | 耐久性のある部品と簡単なアクセス |

あなたのラインに適したスクラップタイヤカッターを手に入れよう

効率を向上させ、手作業を減らし、タイヤの廃棄を削減したいですか?標準的なトラックタイヤでも、大型のOTRタイプでも、Shuliyにはあなたの生産規模と予算に合ったタイヤカッター機械が販売されています。

📩 今すぐお問い合わせください。理想的なタイヤカッティングマシンのセットアップに関する見積もり、技術仕様、およびレイアウトプランを取得できます。