PET bottle crushing machine is a device specifically designed to crush discarded plastic bottles and is widely used in plastic bottle recycling lines. It typically employs highly efficient mechanical pressure or cutting techniques that enable plastic bottles to be quickly and efficiently processed into small pieces or fragments, thereby reducing their size and facilitating storage, transportation, and subsequent reuse.

Raw Materials And Products Of PET Bottle Crusher

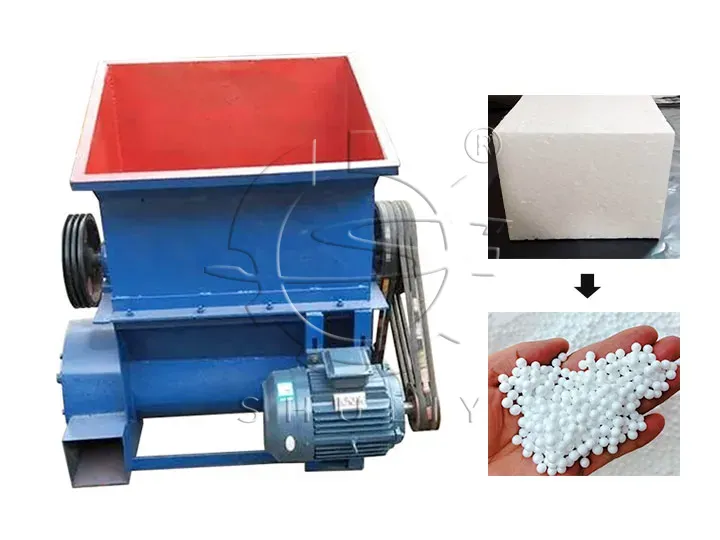

PET bottle crushing machines can crush and process various types of plastic bottles, such as beverage bottles, shampoo bottles, etc., with high efficiency. The crushers cut the PET plastic bottles into small pieces or fragments by powerful force and high-speed rotating blades, which in turn are processed into finished crushed PET bottle flakes.

These bottle flakes can be used in the production of recycled plastics to make new plastic products such as fiber fillers, recycled PET fibers, plastic flakes, etc., which provide an important source of raw materials for recycling.

Plastic PET Bottle Crusher Machine Working Principle

The water bottle crusher machine utilizes high-speed rotating blades and rotating shafts to crush and shred the bottle. When the plastic bottles are placed in the machine, the PET bottle crusher machine blades begin to rotate at a high speed while the spindle is acted upon to rotate the blades. The plastic crusher blades are usually designed with sharp edges that effectively cut and tear plastic bottles. As the bottle is fed inside the machine, the blades cut it into smaller pieces and pulverize them with the force of the rotation. Ultimately, the pieces of plastic bottles are compressed into smaller particles for easy subsequent processing and reuse.

Throughout the process, the screen with so many holes is responsible for sifting out flakes that are not of the required size. The size of the screens is customized and can be adjusted by customers according to their needs.

PET Water Bottle Crushing Machine Parameters

Here are the basic parameters of our hot-selling PET bottle crusher. We offer a wide range of models with capacities of up to 3000 kg/h that are designed to meet your specific requirements. If you are interested in a plastic bottle crusher, please feel free to contact us. We can also customize the design according to your requirements to ensure you get the most suitable solution for your business needs.

- Capacity (kg/h): 500

- Motor (kW): 22

- Height (m): 1.8

- Knives (pcs): 8

- Cutter thickness (mm): 30

- Thickness of steel plate (mm): 16

- Diameter (mm): 377

- Capacity (kg/h): 1000

- Motor (kW): 37

- Height (m): 2.6

- Knives (pcs): 10

- Cutter thickness (mm): 40

- Thickness of steel plate (mm): 20

- Diameter (mm): 425

- Capacity (kg/h): 1500

- Motor (kW): 75

- Height (m): 2.6

- Knives (pcs): 10

- Cutter thickness (mm): 40

- Thickness of steel plate (mm): 30

- Diameter (mm): 125

- Capacity (kg/h): 3000

- Motor (kW): 90

- Height (m): 2.6

- Knives (pcs): 12

- Cutter thickness (mm): 40

- Thickness of steel plate (mm): 30

- Diameter (mm): 500

Plastic Bottle Cutter Features

- Plastic bottle crusher usually adopts blades made of high-quality alloy steel, these blades are sturdy and durable, can effectively cut and crush plastic bottles, are not easy to wear out after a long time of use, and have a long service life.

- Plastic bottle crusher is very versatile and can be used to process various types of plastic bottles, including beverage bottles, detergent bottles, etc., which can meet the needs of different industries and scenarios.

- According to customers’ needs, the Shuliy PET bottle crusher can be customized with different specifications and models to meet the needs of different scales and types of production, providing customers with personalized solutions.

- The crusher adopts advanced design and technology with highly efficient crushing capacity, which can quickly and thoroughly crush plastic bottles into small particles, improving processing efficiency and saving time and cost.

Shuliy Plastic Bottle Cutter Helps Your Plastic Recycling Business!

Water Bottle Crusher Machine Sent To Tanzania

Not long ago, a plastic recycling plant located in Tanzania purchased a PET bottle crusher from our company. In the past, the enterprise faced the problem of inefficient disposal of waste PET plastic bottles, which led to increased production costs and waste of resources. Introducing our plastic crusher successfully solved the problem of waste plastic bottle processing, improved the recycling efficiency, and reduced the production cost.

Plastic Bottle Cutter In Plastic Bottle Recycling Plant

The whole plastic bottle recycling plant mainly consists of a feeding system, crushing system, washing system, and drying system. PET bottle crusher is usually used at the second stage, which is after plastic bottles have been de-labeled and before they are cleaned. Its function is to crush plastic bottles into small pieces for subsequent cleaning. Utilizing the plastic cutter machine can improve recycling capacity efficiently. The video of the workflow is as follows.

Considerate Service Of Plastic Crushing Machine

Shuliy is dedicated to providing comprehensive pre-sales, on-sales, and after-sales services to ensure a worry-free shopping experience for each customer.

- Pre-sales: We provide professional consultation and personalized customization services to help customers select the most suitable machines.

- On-sales: During the purchase, we are available to answer any questions and assist customers with their orders as soon as possible. We offer detailed technical information on PET bottle crushers. Besides, we ensure timely delivery of machines and offer various payment methods to meet different customer preferences.

- After-sales: We promise a one-year warranty at no extra cost and on-site installation service if you need it. What’s more, if there are some bad parts of the PET bottle crusher, it can be re-sent by express delivery.

Plastic Bottle Cutter Machine Price

When it comes to the price of PET bottle crusher, we offer a wide range of models and specifications to meet different needs. Costs vary depending on factors such as model, production capacity, and features. You are welcome to contact us and we will provide you with a detailed quote based on your specific requirements and provide you with equipment options that best suit your needs!