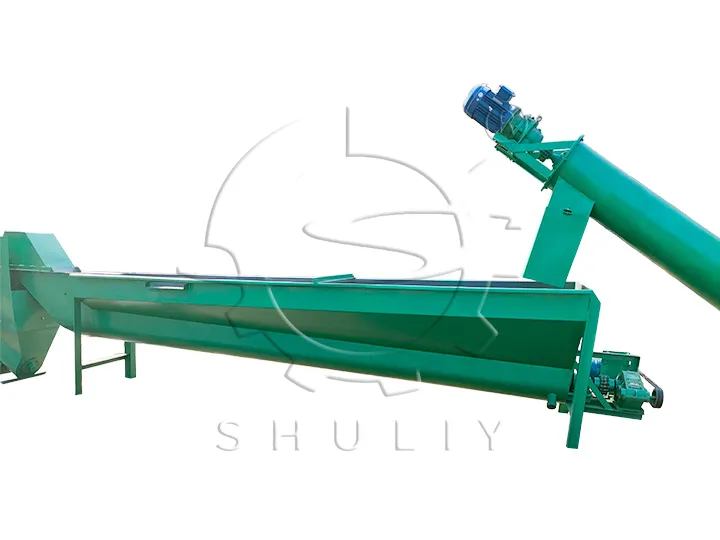

The Shuliy PET bottle washing plant has been successfully installed and commissioned in Mozambique, providing an efficient and reliable solution for the customer. The PET bottle flakes washing line consists of plastic crusher, plastic bottle washing machine, plastic dewatering machine, conveyor belt, etc.

Customer persistence and choice

The Mozambican customer specializes in plastic recycling, and the quality of the machine was one of his primary considerations. They needed the PET bottle washing plant to be able to run consistently and efficiently to process large quantities of plastic bottles. In addition, the capacity of the PET bottle recycle machine was also important to them, and they wanted the new washing line to be able to increase productivity while maintaining quality. In addition to this, they were also concerned about the installation and commissioning process of the machine, as well as the training of operators and the ease of use of the equipment.

After extensive market research and comparisons, the customer finally chose the PET bottle washing plant from Shuliy, which is well-known in the industry for its outstanding quality, reliable performance, and professional after-sales service. The PET bottle washing recycling machine they provide is not only of high productivity and consistent quality but also easy to operate and maintain.

PET bottle washing plant technical data

| Item | Description | Item | Description |

| Conveyor belt | Convey the bottle to PET label removing machine Power: 3kw Length: 4m Width: 0.6m | Plastic label removing machine | Remove the label from the PET bottle Power: 15kw+1.5kw Diameter 0.63m Length: 4.3m Weight: 2600kg |

| Picking conveyor | Sort out bottles with incompletely removed labels Power: 3kw L6m*W0.6m | Plastic bottle crusher | Crush the bottle into small flakes Height: 2.6m Power: 37+4+3kw Model: SL-80 Capacity: 1000kg/h |

| Plastic chips washing machine | Separate PET chips and PE bottle cap Power: 3kw5*1.0*1.1m | PET bottle flakes hot washing machine | Wash PET flakes with hot water and a cleaning agent Power: 60kw+4kw(electromagnetic heating) Width: 1.3Height 2m |

| Rubbing washing machine | With water recycling, clean the PET bottle enough, remove cleaning agents and other impurities Power: 7.5kw L3*W0.4m | Plastic dryer machine | Dewatering for PET flakes Power: 15kw Size: L 2.5*W0.75m |

Smooth delivery and commissioning

After signing the contract, the Shuliy team moved quickly to arrange production and shipment according to the customer’s needs and schedule. After careful packing and transportation, the washing line arrived smoothly at the customer’s plant in Mozambique. Upon arrival, Shuliy’s team of engineers was involved in the installation and commissioning of the PET bottle washing plant and provided professional training to the customer’s operators.

After a period of trial and adjustment, Shuliy’s PET bottle washing line has been successfully put into production. The customer is very satisfied with the operation of the equipment, the quality of the PET flakes is excellent and the production capacity has been significantly increased.