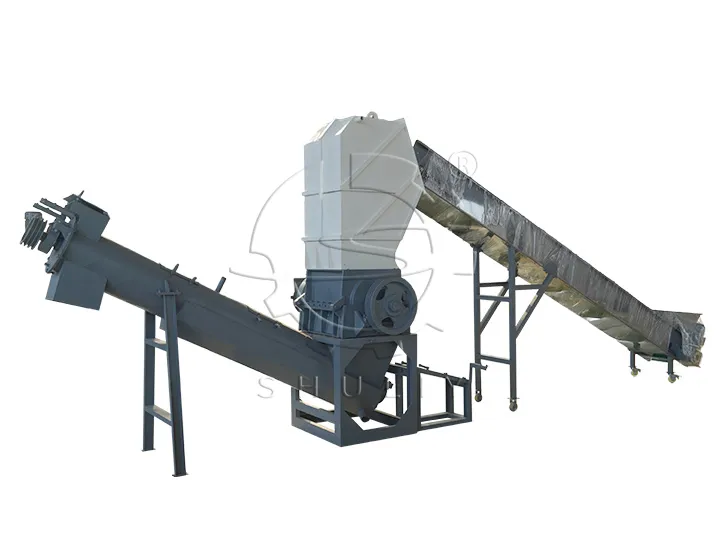

A regular Shuliy customer from Cote d’Ivoire has once again purchased plastic film recycling machines, including plastic granulators, plastic crushers, plastic pellet cutters, etc. The plastic recycling process equipment has been successfully delivered to the customer’s plant and has been put into operation without any problems. Feedback from the customer shows that the equipment has improved the efficiency of plastics recycling and reduced costs at the same time.

Customer background and needs

This Ivorian client owns a company that specializes in plastic recycling and is one of the leading plastic recycling equipment manufacturers in the region. They are dedicated to collecting and recycling all types of waste plastics and reprocessing them into high-quality recycled plastic pellets that fetch a good price in the market.

This Ivorian customer has always had a good relationship with Shuliy. They had purchased Shuliy’s plastic pelletizing machines in their previous dealings and had a full base of trust in their performance and quality. Due to the continuous expansion of their business, the customer was in urgent need of upgrading their equipment in order to improve production efficiency and ensure product quality. So they sought Shuliy’s help again to upgrade their plastic film recycling machine to process plastic waste more efficiently.

Shuliy’s professional services

Based on the long-term cooperation with the customer, Sunny, Shuliy’s sales manager, immediately responded to the customer’s needs and demonstrated Shuliy’s sincerity and capability as a partner through timely and professional communication and service. Sunny provided the customer with detailed product information about the plastic film recycling machine, including pictures of the machine, and a video of the test run.

Sunny not only provided the basic information, but also patiently answered all kinds of questions raised by the customer, and introduced the details and technical parameters of the plastic granules extrusion line in detail. Her professional knowledge and sincere attitude made the customer feel the professionalism and integrity of Shuliy team, which further strengthened the willingness of both parties to cooperate.

Plastic pelletizing recycling machine parameters

| Item | Specification | Item | Specification |

| Plastic crusher machine | Model: SLSP-600 Power: 22kw Capacity: 600-800kg/h Knives: 10pcs Knives Material: 60Si2Mn | Conveyer belt | Power:.5.5kw Length:3m Diameter:325mm |

| Plastic drying machine | Power: 11kw Diameter:530mm H: 2.5m | Automatic feeder | Make raw materials better enter the host Power:2.2kw |

| Plastic pelletizing machine | Host pellet making machine Model: SL-150 Power: 37kw 2.3m screw Heat Method: ceramic heating Hardened gear reducer Second pellet making machine Model: SL-125 Power: 11kw 1.3screw Heating method: heating ring heating Hardened gear reducer Electric grinding head Screw material:40Cr(High hardness and wear resistance) Sleeve material:heat-treated No.45 steel | Plastic pellet cutter | Converter speed regulation Power :3kw Hob knives |

This is the parameter information of the plastic pelletizing recycling machines shipped to Côte d’Ivoire. Shuliy also provides other models and specifications of recycling machines, we can also provide customized machines according to different plastic recycling needs, if there is a need, please feel free to contact us for a customized solution.

Successful delivery of plastic film recycling machine

After thorough communication and preparation, Shuliy plastic film pelletizing line was successfully shipped to the customer’s plant. This recycling line contains the most advanced technology and plastic pelletizing recycling machine, which can effectively convert waste plastics into high-quality recycled pellets.

Soon after receiving the plastic film recycling machine, the customer put it into operation. Through a period of trial and adjustment, the plastic pelletizing line began to work normally and achieved satisfactory production results. The conversion rate from plastic waste to recycled pellets was greatly improved, and the production efficiency was also significantly increased.