Полуавтоматическая линия переработки отработанных шин Shuliy является надежным и экономически эффективным решением для преобразования старых шин в ценные резиновые блоки, гранулы и порошок. Она идеально подходит для переработки в малых масштабах и была экспортирована в Канаду, Катар и многие другие страны, где была хорошо принята!

Применение линии по переработке отходов шин

Эта линия по переработке отработанных шин обрабатывает шины размером до 1200 мм, включая автомобильные и грузовые шины и т.д. Она может использоваться переработчиками шин, производителями резинового порошка и производителями изделий из переработанной резины.

Через предварительную обработку, измельчение, шлифование и сортировку, конечный продукт включает в себя :

- Регулируемые по размеру (10-40 меш) резиновые чипсы, гранулы и порошок

- Чистота резины ≥ 99%

- Подходит для прямого промышленного использования

Основные характеристики наших машин для переработки шин

- Широко применима и производит высококачественную резиновую пудру или гранулы, подходящие для прямого промышленного использования.

- Изготовлено из износостойких материалов, таких как высококачественная нержавеющая сталь и 5Cr6MnMo, оборудование предлагает долгий срок службы с минимальным обслуживанием.

- Простота в эксплуатации, для всей линии требуется всего 2-4 работника.

- Энергоэффективность. Для производства 1000 кг резиновой пудры требуется всего 150–180 кВтч, что позволяет сэкономить до 30–40% энергии по сравнению с традиционными системами.

- Компактный дизайн уменьшает требования к площади.

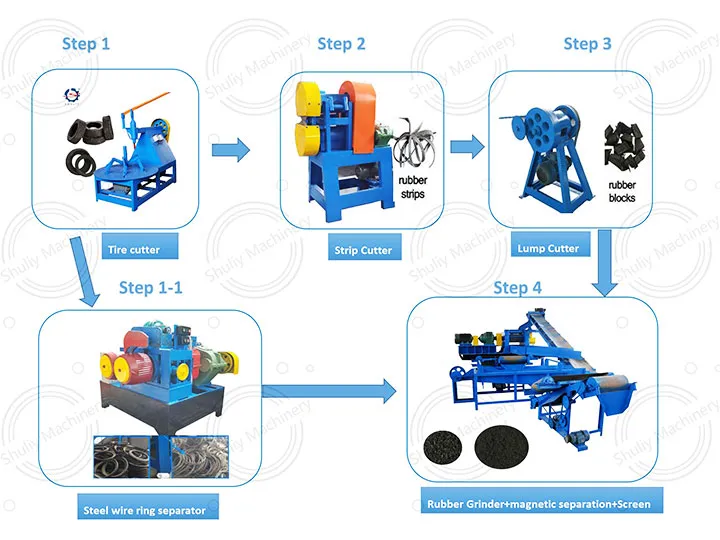

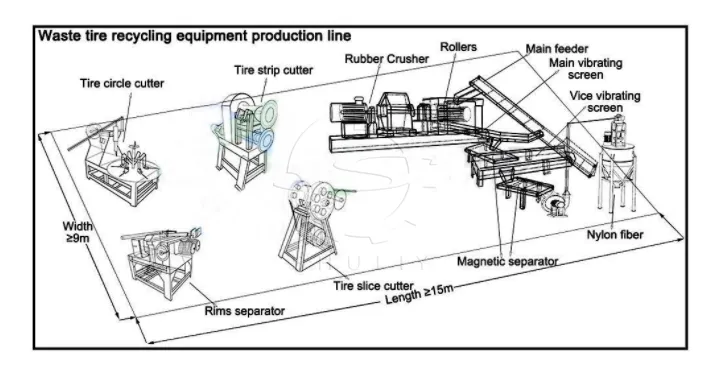

Полный процесс переработки шин

Резак для боковин шин: Режет и удаляет боковину шины, содержащую стальные проволоки.

- Производительность: 40 шт/ч

- Мощность: 4+0.75 кВт

- Выход: Снятые стальные проволоки от шин

Резак для шин: Режет резиновые шины на длинные полосы для более легкой переработки.

- Производительность: 1000 кг/ч

- Мощность: 5.5 кВт

- Выход: Резиновые чипсы 3-5 см

Резак для шин: нарезает полоски на резиновые блоки.

- Производительность: 800/1500 кг/ч

- Мощность: 5.5/18.5 кВт

- Выход: блоки 5*5*5 см

Система измельчения и магнитного разделения: дополнительно очищает резину и удаляет остатки стали.

- Производительность: 80-2300 кг/ч

- Выход: резиновый порошок 10-40 сетка (0.63-2.5 мм)

Сепаратор волокон: отделяет текстильные волокна для достижения высокочистого выхода резины.

- Производительность: 800-1000 кг/ч

- Мощность: 5.5 кВт

- Выход: резиновый порошок с чистотой более 99%

Почему стоит выбрать линию по переработке шин Shuliy

- Мы предлагаем конкурентоспособные цены и низкие инвестиционные затраты, что делает нас подходящими для маломасштабных или стартап-фабрик.

- Мы предоставляем индивидуальные решения по переработке шин в соответствии с вашими производственными потребностями.

- Мы также предоставляем техническое руководство, установку под ключ и другие услуги.

- Мы предлагаем однолетнюю бесплатную гарантию и пожизненное обеспечение запасными частями.

- У нас есть опыт в экспорте, и мы знакомы с потребностями клиентов по всему миру в отношении таможенной очистки, установки и послепродажного обслуживания.

Как начать бизнес по переработке шин?

Начать бизнес по переработке шин несложно. Вам потребуется надежное оборудование, подходящее место, достаточное количество сырья и рабочие. Как опытный поставщик оборудования для переработки изношенных шин, Shuliy помогла многим клиентам построить эффективные перерабатывающие заводы. Выбрав нашу экономичную полуавтоматическую линию по переработке изношенных шин, вы можете сократить как затраты на оборудование, так и эксплуатационные расходы — для начала производства требуется всего 2–4 рабочих.

Не стесняйтесь обращаться к нам за индивидуальным решением!