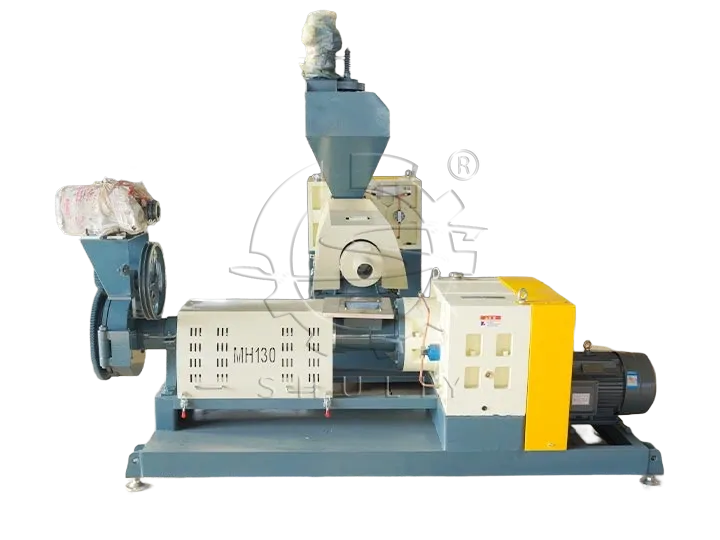

The Shuliy plastic pelletizer machine can effectively grind post-consumer and post-industry plastic scraps into regrind granules with a capacity ranging from 180~420kg/h. It adopts physical recycling methods including melting, drawing, cooling, and cutting to pelletize, and is suitable for all sizes of factories.

- Raw Materials: Post-consumer and post-industry plastics made of PP, PE, PVC, LDPE, HDPE, etc.

- Final Products: High-quality regrind granules

- Capacity: 180~420kg/h.

- Application: PP, PE, PVC, HDPE, etc. plastic recycling line

Key Highlights of the Shuliy Plastic Pelletizer Machine

Raw Materials and Products of Plastic Pellet Extruder Machine

Raw Materials

The shuliy plastic pelletizer machine can effectively recycle PP, PE, PVC, HDPE, and LDPE, converting them into reproduction pellets, which can be collected from the following products:

Post-consumer Plastic

- Packaging Plastic: Woven bags, raffia bags, stretch films, shrink films, Bopp films, etc.

- Daily Items: Plastic toys, disposable food boxes, HDPE milk bottles, etc.

- Electronics: Plastic case, wire insulation, etc.

Post-industry Plastic

- Injection trimmings: Waste plastics generated during the injection molding process.

- Extrusion trimmings: Waste plastics generated during the extrusion molding process.

- Film trimmings: Waste plastics from the film production process.

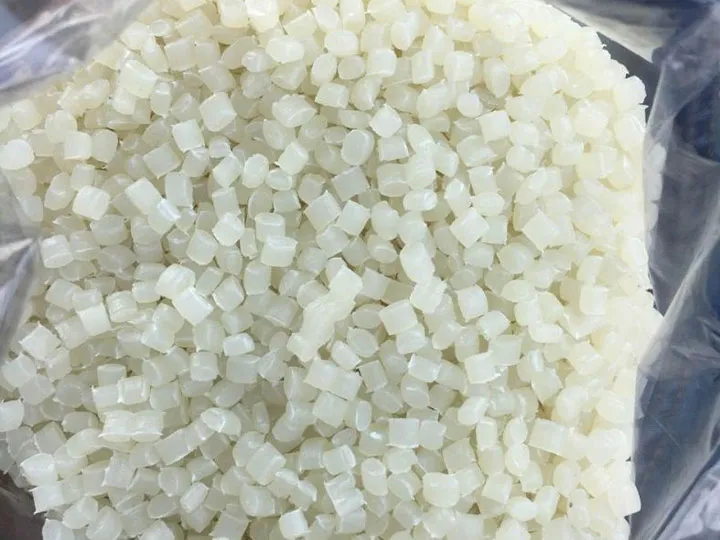

Final Product

By utilizing this special plastic pelletizer machine, we can obtain high-quality plastic regrind granules, which have improved their mechanical properties such as shrinkage, heat resistance, creep resistance, and impact resistance. These granules can be directly utilized in the film-blowing production line and other applications.

How Does the Plastic Film Recycling Machine Work?

- Feeding: Large-capacity hoppers can support the rapid operation of the granulation system, effectively improving production efficiency.

- Heating: Multiple heating methods, including electromagnetic heating, ceramic heating, and iron plate heating, efficiently and rapidly melt the plastic into a liquid state.

- Extruding: The screw drives the molten plastic into the mold head, where the plastic is plasticized and then extruded into a strip-shaped material.

- Cooling: In the stranding granulation line, long strips are cooled in the tank before being cut. Conversely, plastic is cut directly and cooled within the recirculating water flow in the water-ring system.

- Cutting: Both the strand pelletizing system and the water-ring unit can effectively transform extruded plastic into uniform granules.

Plastic Recycling Extruder Machine Parameters

The following table shows the specifications of several popular granulators. Different models have different sizes and power, etc. You can choose the most suitable type according to your needs. If you want other sizes of machines, we can also provide customized service. Please feel free to contact us.

| Type | SL-125 | SL-135 | SL-150 | SL-180 | SL-210 | SL-220 |

| Screw diameter | 125mm | 135mm | 150mm | 180mm | 210mm | 220mm |

| Spindle speed | 50-70/min | 40-50/min | 40-50/min | 40-50/min | 40-50/min | 40-50/min |

| Main motor power | 30kw | 37kw | 37kw | 55kw | 75kw | 90kw |

| Reducer hard gear | 225 | 250 | 250 | 280 | 315 | 330 |

| Weight | 1.8T | 2T | 2T | 2.2T | 2.8T | 3.2T |

| Size | 2.6*0.7*0.7m | 2.8*0.7*0.7m | 3.0*0.7*0.8m | 3.2*0.7*0.8m | 3.5*1*1m | 3.8*1.2*1m |

| Output | 180KG/H | 200KG/H | 300KG/H | 350KG/H | 380KG/H | 420KG/H |

The Main Structure of Plastic Granulator

Basic Structure

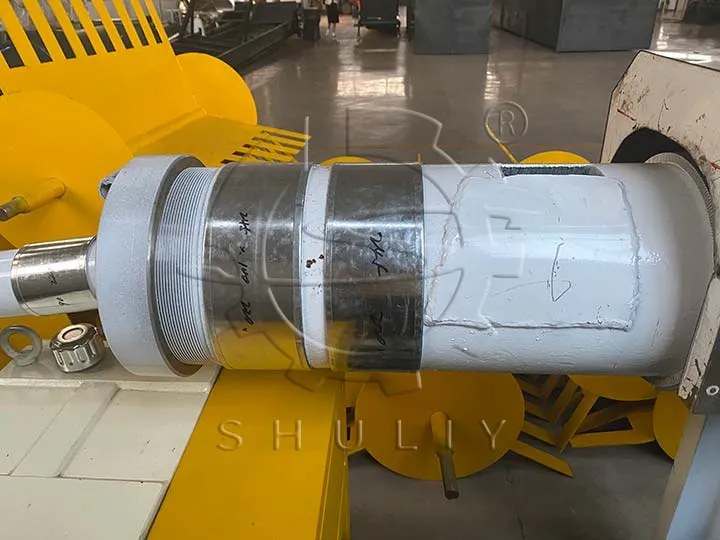

The plastic granulator’s main structure includes a feed inlet, screw press, pressing chamber, heating device, discharge inlet, die head, and reducer. Waste plastic enters the machine through the inlet, and under the action of the screw press, the material is compressed and sent into the pressing chamber. The press chamber is equipped with a heating unit to heat the plastic to achieve the right pelletizing temperature.

Subsequently, the plastic is extruded into long strips through the die head. A speed reducer regulates the operating speed and torque of the entire system. Since the diameter, length, and distance of the screw from the barrel wall vary according to the different pelletizing materials, one plastic pelletizer machine cannot handle several materials at the same time and needs to be adjusted according to the specific situation.

3 Heating Methods for Plastic Pelletizer Machine

Plastic pelletizers usually use three different heating methods: electromagnetic heating, ceramic heating devices, and iron heating devices. Different heating methods have different capacities and advantages. Choosing the right one depends on production needs and budget considerations.

Electromagnetic heating utilizes the induction of electromagnetic field to heat the plastic material, which is fast, efficient, and can precisely control the heating temperature, and is suitable for the production process with higher temperature requirements.

The ceramic heating device through the ceramic resistance heating plastic, with uniform heating, and good stability, is suitable for some of the more stringent requirements of the temperature distribution of production scenarios.

The iron heating device is the use of iron or iron wire heating plastic, simple to operate, and low cost.

3 Types of Mold Heads for Plastic Pelletizer Equipment

Die heads for plastic pelletizer machines are usually divided into three main types: electric gear die heads, automatic slag filters, and hydraulic die heads, each of which has unique features and advantages. You can choose the right type according to your production needs and material characteristics to improve production efficiency and product quality.

The electric gear die head realizes the production of plastic granules through an electric gear system, which is characterized by high efficiency and stability, and is suitable for large-scale production needs. When changing the net inside, its door needs to be opened.

The automatic slag filter has a built-in screen system that automatically filters out impurities and residues and discharges them on the right side, ensuring that the quality of the pellets produced is pure and that subsequent processing costs are reduced. It is typically utilized to process dirty plastic materials.

The hydraulic die head utilizes a hydraulic system to control pressure and temperature, enabling precise processing and adjustment of the plastic material, making it suitable for production scenarios that require high pellet quality. Furthermore, the net of the hydraulic die-head can be changed without the need to open its door.

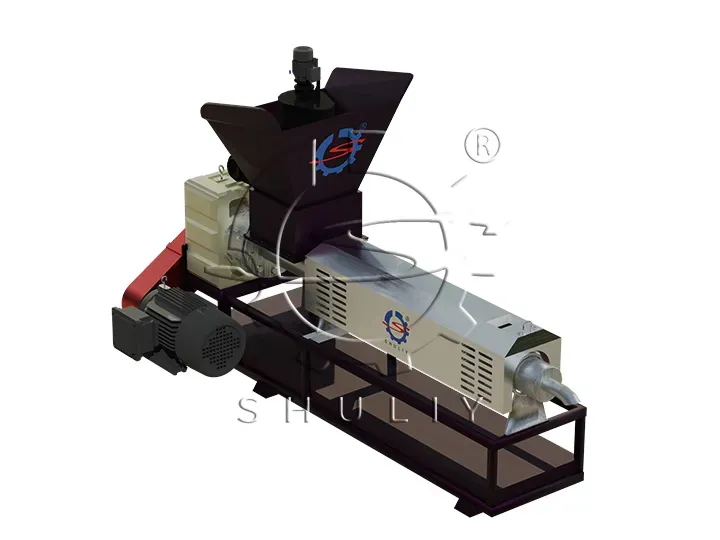

2 Kinds of Pelletizing

Water ring granulation is suitable for nearly all thermoplastic materials and is appropriate for high-volume applications. It works by converting plastic into granules through a rapidly rotating circular cutting machine. After pelletizing, granules are cooled by the cooling tank.

Strand pelletizing utilizes the method of first extruding and cooling, and then cutting it to form pellets. It is suitable for nearly all thermoplastic materials and offers high-cost performance.

Plastic Pelletizing Machine Factory

A plastic pelletizer machine is one of the core equipment in the plastic pelletizing plant, which works together with a plastic crusher, plastic washing machine, plastic cutting machine, etc. to form a complete plastic pelletizing line, which improves the production efficiency and quality of plastic granules, ensures the high efficiency of the production process and the stability of the quality of regenerated plastics. As a professional manufacturer of plastic pelletizer machines, Shuliy warmly welcomes customers to visit our plastic pelletizing machine factory to witness the whole process of plastic pelletizing and learn about our production process and plastic pelletizer machine performance.

Delivery Case: Plastic Granulator Is Sent to Many Countries!

Pelletizer Equipment Sent to Nigeria Successfully

A customer from Nigeria, who operates a plastics recycling plant, urgently needed to improve production efficiency and quality in the face of increasing demand for plastic scrap processing. By purchasing an advanced plastic granulator from our company, the customer successfully solved his challenges in raw material handling and pellet production. Our plastic pelletizer machines not only increased production efficiency but also improved the quality of pellets, making his products more popular in the market.

The Best Plastic Extruder Machine Price

Welcome to our latest model of plastic pellet extruder, designed to provide excellent performance and reliable quality for your production. No matter what waste plastics you need to process, our plastic pelletizer machines will meet your needs. Through advanced technology and sophisticated manufacturing processes, our machines can efficiently convert waste plastics into high-quality plastic pellets, helping you realize efficient production and reduce costs. Contact us now to learn more and get a quote!