直径が1200mm未満のタイヤのリサイクルにおいて、切断段階での精度は、下流の効率に直接影響します。タイヤのサイドウォールが取り除かれ、ストリップが切断された後、次のステップはそれらのストリップを清潔で均一なブロックに変換することです。そこで、タイヤブロック切断機が不可欠になります。

タイヤブロックカッターとは何ですか?

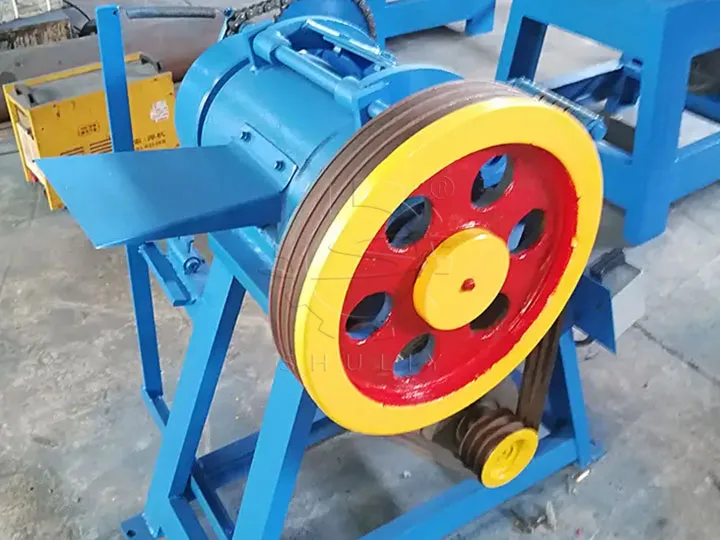

タイヤブロックカッター(タイヤブロック切断機または廃タイヤブロックカッターとも呼ばれる)は、廃タイヤから長いゴムストリップを小さく扱いやすいブロック(通常3〜6 cmのサイズ)に切断するために設計されています。これらのブロックは、シュレッダー、グラインダー、または粉砕機に供給して、さらにゴムの粒子や粉末に加工するのに最適です。

この機械は給餌効率を向上させ、設備の負担を軽減し、半自動タイヤリサイクルラインにおける出力の一貫性を改善します。

タイヤブロックカッターの主要仕様

異なる能力と予算に合わせた2つのモデルを提供しています:

| 特徴 | QKJ-358 一般タイヤブロックカッター | 更新されたタイヤブロックカッター |

|---|---|---|

| モーター出力 | 5.5 kW | 18.5 kW |

| 容量 | 800 kg/h | 1500 kg/h |

| カッティングサイズ | 3*5*6 cm | 5*5 cm |

| 機械サイズ (L*W*H) | 1.0*0.8*1.4 m | 1.3*1.1*1.5 m |

| 重さ | 800 kg | 1200 kg |

なぜ廃タイヤブロックカッターが必要なのか?

ゴムストリップを小さなブロックに切断することには、いくつかの重要な利点があります:

- グラインダー/シュレッダーのための改善された給餌 – 均一なブロックはより均等に供給され、機械のストレスを軽減します。

- より良い出力制御 – 一貫したサイズは下流の製品品質を向上させます。

- 労働の削減 - 手動切断の必要を排除します。

- スペース効率 – 長いストリップと比較して、保管や輸送が容易です。

- 安全性 – 保護装置を備えた封閉型切断室は、オペレーターの保護を確保します。

タイヤブロックカッターはどのように機能しますか?

- 給餌:切断されたタイヤゴムストリップをタイヤブロック切断機の給餌口に置きます。

- クランプと固定:油圧システムがゴムストリップをしっかりと固定し、切断プロセス中に動かないようにします。

- 回転切断刃の作動:カッターシャフトの高強度合金刃がモーターによって駆動され、ゴムに切り込むために回転します。

- タイヤは切り刻まれます。全体のタイヤは、約5cmの規則的な塊に切り刻まれ、リサイクルのためにその後の粉砕に備えます。

- 完成品が排出されます。切断されたタイヤブロックは駆動ベルトを通過し、粉砕プロセスに入ります。

リサイクルラインへのシームレスな統合

このゴムタイヤ切断機は、以下のものと組み合わせて使用するのが最適です:

- 🔗 タイヤストリップ切断機 – タイヤのサイドウォールを扱いやすいストリップにカットします。

- 🔗 セミオートマチックタイヤリサイクリングライン – 中規模の運用に対するコスト効果の高いソリューション。

- 🔗 最終処理のためのゴムグラニュレーター、シュレッダー、粉砕機。

この機械は誰が必要ですか?

- ゴム粒子製造業者

- リサイクルゴム粉末製造業者

- タイヤシュレッダー工場

- タイヤリサイクル事業

- ゴム再生工場

車のタイヤ、トラックのタイヤ、バスのタイヤを処理する場合でも、この機械は最も重要な場所で効率を提供します。

なぜ私たちのタイヤブロックカッターを選ぶのですか?

- 強力で耐久性のあるブレードシステム

- 下流使用のための一貫したブロック出力

- 特定のアプリケーション向けのカスタマイズ可能なサイズ

- 低メンテナンスでユーザーフレンドリーな操作

- 過酷な環境での重作業用に設計されています

今日見積もりを取得する

リサイクル作業をアップグレードする準備はできていますか?私たちのタイヤブロックカッティングマシンは、高効率のゴム処理のためのスマートなソリューションです。今日中にカスタマイズされた見積もりや完全なタイヤリサイクルラインの提案を受けるために、お問い合わせください。