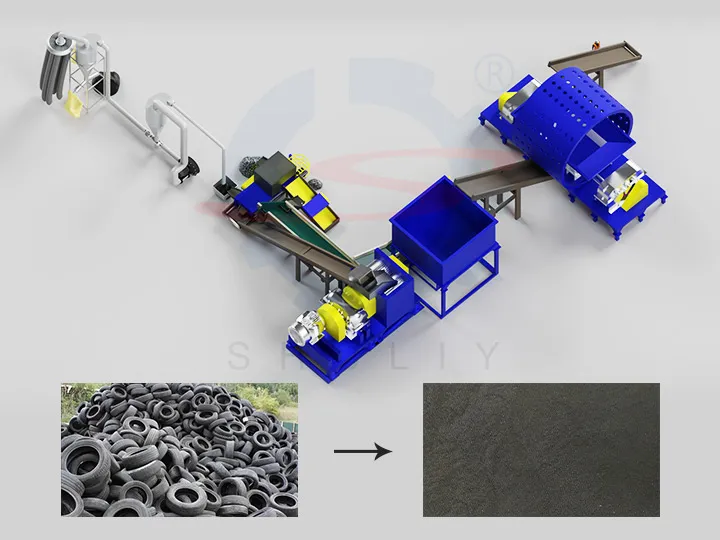

Полностью автоматизированный завод по переработке резины эффективно преобразует отработанные шины (≤1200 мм) в резиновую пудру с помощью интеллектуальной системы управления PLC, что делает процесс более эффективным, безопасным и менее трудоемким. С оборудованием Shuliy вы можете перерабатывать шины для производства резиновой пудры с размером частиц от 10 до 40 меш, которая подходит для переработанных резинок и эффективно отделяет стальную проволоку, волокна и другие примеси для сортировки и переработки.

Применение полностью автоматического завода по переработке резины

Наши полностью автоматизированные линии по переработке отработанных шин разработаны для обработки шин диаметром менее 1200 мм. Они подходят для автомобильных и автобусных шин, среди прочего. С широким ассортиментом моделей оборудования мы можем предложить индивидуальные решения для различных требований по мощности, удовлетворяя потребности переработчиков шин малого, среднего и крупного размера, производителей резиновой порошка и переработанных резинотехнических изделий.

Завод по переработке резины имеет модульную структуру, которая поддерживает покупку всей линии или отдельных машин. Он может производить резиновые блоки, гранулы или порошок различных размеров частиц в зависимости от спроса. Получаемый резиновый порошок более чем на 99% чистый и стабильный, и может быть использован непосредственно в промышленном производстве.

3 Горячие линии по производству резинового порошка

Линия переработки резины от шин:

Процесс: машина для удаления бортов шин → машина для резки шин → шредер для шин → дробилка для шин и магнитные сепараторы → сепаратор волокон

Процесс работы:

- De-wire: Машина для снятия проволоки с шин может эффективно извлекать полные обода с помощью гидравлического давления и устройства для зажима крюком. В среднем она может резать 20-50 шин в час.

- Резка: машина для резки шин разрезает废轮胎 на несколько сегментов с производительностью 60 шин/ч.

- Шредирование: блоки шин измельчаются на однородные куски размером 50-100 мм с максимальной производительностью 20 т/ч.

- Шредирование: она измельчает блоки шин на однородные куски размером 50-100 мм с максимальной эффективностью 20 тонн в час.

- Шлифование и сортировка: Измельчает резинотехнические изделия и производит резиновый порошок с различными размерами частиц (10-40 меш) путем изменения экранов. Два магнитных сепаратора эффективно удаляют мелкие стальные проволочные примеси.

- Сепаратор волокон: дальнейшее удаление и сбор волокон из резинового порошка с использованием принципа воздушной сепарации.

Линия по разрушению шин и удалению проволоки

Рабочий процесс: машина для снятия и резки бортов шин→разделитель стальной проволоки шин→шредер резиновых шин→шина-мельница и магнитный сепаратор→машина для отделения волокон

Процесс работы:

- Полуразрушение: обрезка бортов удаляет стальную проволоку, а затем следует обрезка нескольких секций оставшейся шины.

- Отделение бортов: Эффективное удаление резины с проволоки бортов шин.

- Измельчение: Поместите резину в измельчитель и раздробите её на куски размером 50-100 мм.

- Помол и сортировка: То же самое, что и на первом заводе по переработке резины.

Линия прямой резки

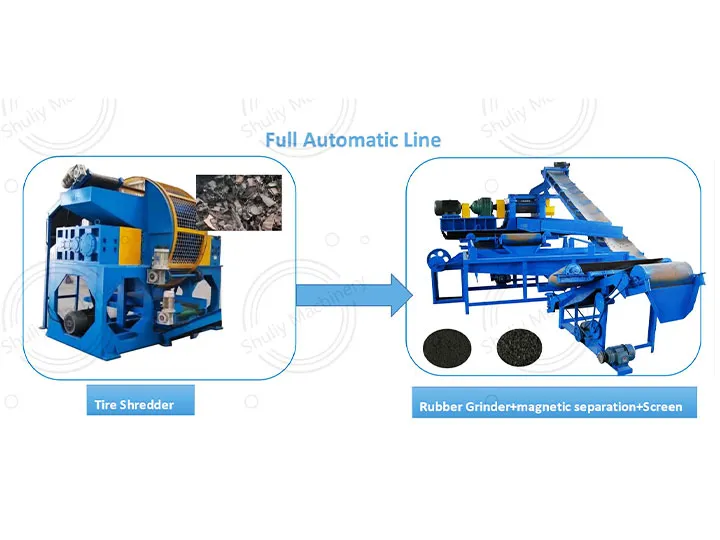

Рабочий процесс: промышленный измельчитель шин → шлифовальный станок для шин и система магнитного разделения → разделитель волокон

Выбирая шредеры для шин модели 1200 и выше, вы можете напрямую проводить процесс измельчения, шлифования и удаления связующих без предварительной обработки. Это решение более эффективно и подходит для крупных заводов, стремящихся к эффективности.

Почему стоит выбрать машины для переработки废 шин Shuliy?

- Предоставляем вам индивидуальные решения по переработке шин

- Автоматизированное интеллектуальное управление процессом переработки, безопасно и эффективно

- Разумная и компактная компоновка оборудования для уменьшения занимаемой площади

- Предоставляем установку под ключ, техническое руководство, годовую бесплатную гарантию и другие услуги

Shuliy успешно предоставляет профессиональные решения по переработке шин в Канаде и других странах и имеет богатый опыт. Свяжитесь с нами сегодня, чтобы узнать больше о том, как мы можем помочь вам инвестировать в или улучшить ваш бизнес по переработке шин!