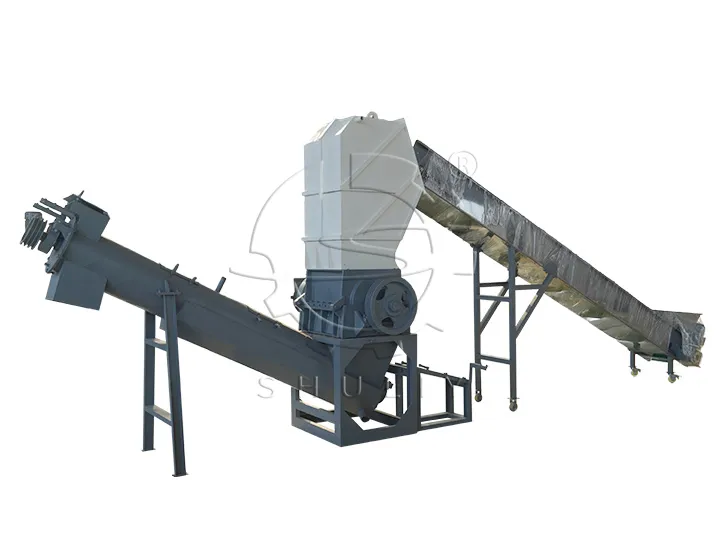

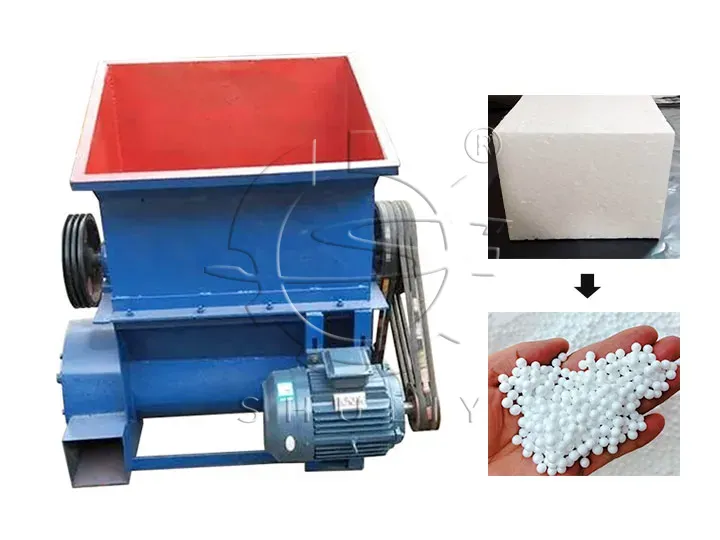

The waste plastic crusher is a kind of equipment specially designed for crushing large waste plastics into small pieces, to facilitate the subsequent pelletizing and recycling process. Shuliy provides various types of plastic crushers for different plastics, and this article is about the plastic shredder for soft plastic. Welcome to contact us at any time to get the details.

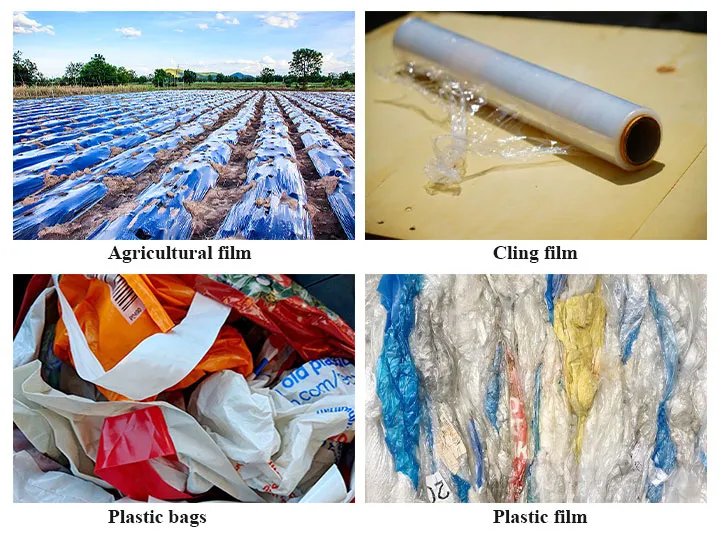

Plastic Film Shredder Application

Raw Materials Of The Waste Plastic Crusher

The waste plastic crusher is mainly used to process all kinds of PP, PE, PVC, and other waste plastic materials. These soft plastics usually come from plastic packaging, plastic bags, woven bags, plastic films, raffia plastics, and other plastic product waste.

Significance Of The Plastic Shredder

Cutting large pieces of plastic into small flakes is an essential step in the plastic recycling line. On the one hand, crushed plastic can reduce storage space and increase the utilization of space resources. On the other hand, using plastic shredders can increase the surface area of the plastic, which is easier to clean up thoroughly and granulate in the next step.

Plastic Shredder Machine Design Structure

The structure of the waste plastic crushing machine mainly consists of the feeding port, crusher body, blade, screen, discharge port, and motor.

- The automatic feeding port is used to convey the plastic waste to the crusher, which is the starting part of the plastic recycling line.

- The waste plastic crushing machine body is the main part of the whole equipment, which is installed with high-strength blades to shear and crush the plastic materials by rotating. And the blades are all made of 60Si2Mn material.

- The design and layout of plastic crusher blades can effectively crush the plastic waste into the required particle size. For example, customers can adjust the gap between the blades to produce plastic flakes in their desired size.

- The waste plastic crusher screen controls the size of the plastic fragments to ensure that the compliant plastic passes through while the larger plastic is blocked.

- The discharge port conveys the crushed plastic pieces out of the waste plastic crushing machine.

- The motor provides the power to drive the whole crushing process. And shuliy can provide three different types of motors. (30KW, 45KW, 55KW)

- The overall structure is simple, compact, easy to operate, and widely used in plastic pelletizing plants. If you’re interested, please feel free to contact us.

Plastic Cutter Parameter

The parameters of several popular models are shown in the following table. We also provide other customized machines according to your needs. If you’d like to learn more, please feel free to contact us.

| Model | SLSP-600 | SLSP-800 | SLSP-1000 |

|---|---|---|---|

| Motor power | 30KW | 45KW | 55KW |

| Capacity | 600-800kg/h | 800-1000kg/h | 1000-1200kg/h |

| Material of knives | 60Si2Mn | 60Si2Mn | 60Si2Mn |

| Number of knives | 10pcs | 10pcs | 10pcs |

| Box width | 600cm | 800cm | 1000cm |

How Does A Plastic Crushing Machine Work?

The working process of the waste plastic crusher is simple and efficient, which usually includes the following steps:

- First, the plastic waste to be processed is put into the inlet of the waste plastic crushing machine;

- Then, through the rotation of the plastic shredder blades, the plastic is cut and crushed into small fragments;

- Next, these plastic fragments pass through the screen to remove impurities and control the size of the plastic;

- Finally, the processed plastic fragments are discharged out of the plastic crusher to wait for the next step of the recycling process.

- The whole workflow of the waste plastic crusher is designed to improve the efficiency of plastic recycling, thus increasing the economic efficiency of the plastic film recycling plant.

Advantages Of Waste Plastic Crusher

- Plastic materials shredder adopts advanced crushing technology and design, which can efficiently crush plastic waste into ideal particle size for subsequent reprocessing or disposal.

- The waste plastic crusher is typically made from high-quality materials and manufactured with precision, ensuring excellent wear resistance and durability. This allows for stable, long-term operation with minimal risk of damage, thereby reducing maintenance costs and repair frequency.

- Shuliy plastic film shredder can be customized and designed according to customer’s needs and specific application scenarios, including crusher size, power, crushing method, feeding method, and other aspects to meet different customers’ needs and requirements.

Recommend Plastic Film Recycling Plant

Waste plastic crusher plays a vital role in plastic pelletizing plants. It is one of the core equipment in the plastic film recycling line and is specifically designed to quickly and efficiently shred waste plastic film into a size suitable for pelletizing. This plastic crushing machine is usually used in conjunction with other equipment such as plastic rinsing tanks and plastic granulators to form a complete recycling system.

Plastic Waste Shredder For Sale

As a professional plastic recycling equipment manufacturer, we offer a wide range of high-efficiency waste plastic crushers with various specifications, which are suitable for processing and reusing all kinds of plastic waste. With robust construction and easy operation, our plastic materials shredder can quickly and efficiently crush plastic waste into reusable pieces. We can provide customized solutions for different production needs. Feel free to contact us for more details and a quote!