Shuliy PET bottle recycling machine is used to effectively recycle all kinds of PET plastic products and some other materials, such as beer bottles. They can be tailored to match your production requirements and are suitable for all sizes of factories.

- Capacity: 500kg~6t/h

- Raw materials: PET plastic products

- Final products: clean and uniform PET flakes

- Applicable objects: plastic recyclers and plastic manufacturers of all sizes

Key Features of the Shuliy PET Recycling Lines

- Widely application.

- High-quality with CE&ISO certification.

- Customizable services satisfy your needs.

- Provide layout designs for your plant

- A one-year warranty, on-site installation, and operation guide.

Process Various Raw Materials into You Want

Raw Materials

Post-consumer Materials:

- PET Plastic Bottles: beverage bottles, food bottles, toiletries bottles, etc.

- PET Fibers: Waste textiles, clothing, carpets, bags, etc.

- PET Shell: Electronic products, toy packaging, etc.

- PET Pallets: PET trays for food packaging and pharmaceutical packaging, etc.

- Other Materials: Beer bottles, etc.

Post-industry Materials:

Waste or scraps produced during the production of EPET products, including PET film scraps, PET preforms, PET fiber waste, PET packaging materials, PET bottles, and so on.

Final Products

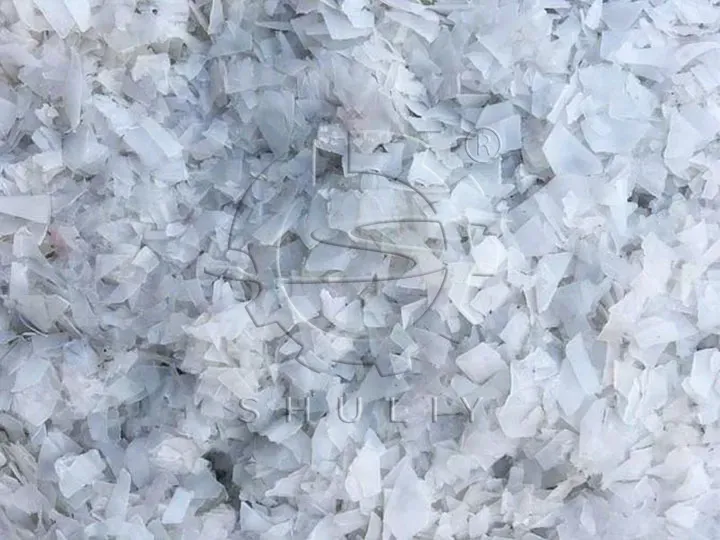

You can obtain clean and uniform PET flakes in the required sizes, which can be reused to produce new PET products. Cleaning PET bottle flakes usually have a certain degree of transparency and mechanical properties and can be used to make a variety of products such as fibers, non-edible bottles, and packaging materials.

How to Achieve Efficient Recycling Processes?

Step 1: Removing Impurities

A label-removing machine is used to remove labels from plastic bottles to ensure the purity of PET bottles.

The label remover achieves consistent production with a capacity of 1~1.2t/h. Its label removal rate is up to 98%, effectively removing impurities from PET plastic.

Equipment List:

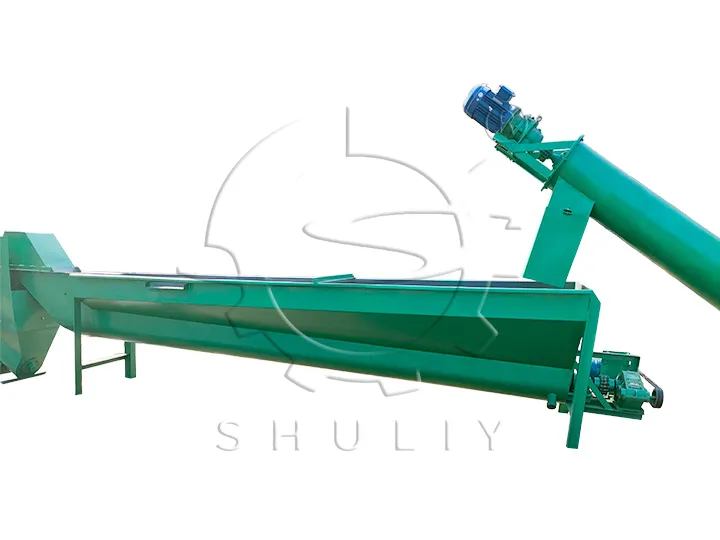

- Conveyor Belt: Transport PET bottles to the remover machine

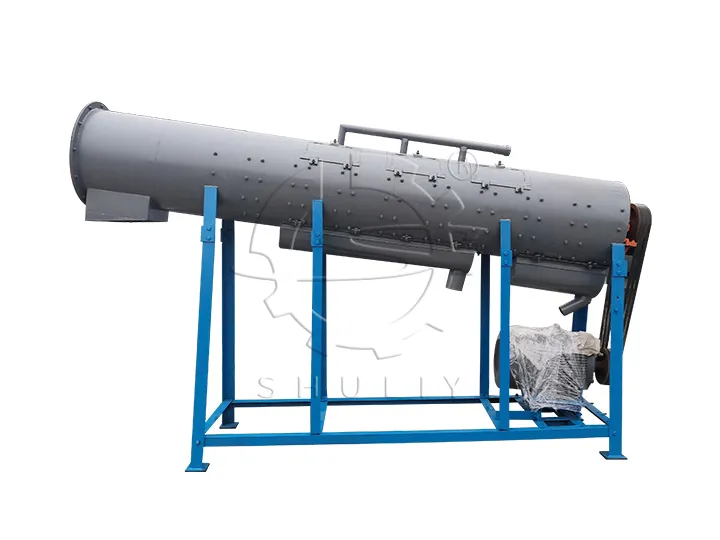

- Tumbler Sieve: Separate various impurities such as stones, metals, glass, etc.

Step 2: Crushing PET Plastic into Pieces

Plastic bottle shredder crushes the plastic bottles to make them into small particles, which is convenient for subsequent cleaning and processing and improves the plastic bottle recycling rate.

The Shuliy plastic crusher for PET bottles features high quality. Its blades are made of 60Si2Mn, which is very durable and resists corrosion. It has a capacity of 500~3000kg/h.

And the PET flakes obtained are around 5~15mm. You can adjust the gap between blades to control the sizes.

Step 3: Washing PET Flakes

There are 3 types of washing machines to deep wash PET plastic bottles, separately named plastic friction washers, sink float separations, and hot washing machines. Through these multiple washing processes, thoroughly remove impurities, such as grease, dirt, etc.

Plastic friction washers use friction and water flow to further clean the plastic bottles, removing residual dirt and foreign matter and ensuring that the recycled plastic bottles meet the standards for reuse.

Sink Float Plastic Separation

Sink float plastic separation is used to clean PET fragments, and separation of PET bottle flakes as well as caps, labels, and other impurities of different materials, improving the purity and quality of recycled materials.

Hot Washing Tank

Hot washing of plastic bottles through high-temperature water or steam. Hot washing tanks can completely remove surface dirt and residue and improve the quality and hygiene standards of recycled materials.

Step 4: Drying the PET Flakes and Store Them

Plastic Drying Machine

The plastic dryer is used to dry the cleaned plastic bottles, removing surface moisture and preparing them for subsequent processing and reuse, improving the quality and stability of the recycled materials.

A Comprehensive Video about Processes

Pre-shipment Demonstration of PET Recycling Line

PET Bottle Recycling Machine Sent To Kenya

A customer from Kenya operates a local PET bottle-washing plant. However, the PET bottle recycling machine in the hands of the customer is aging and cannot meet the increasing demand for recycling. After research and comparison, the customer chose the Shuliy PET bottle recycling machine. Our PET bottle washing line not only has a strong processing capacity but also has an excellent cleaning effect, which greatly improves the production efficiency of the customer. The customer said that by introducing the Shuliy PET bottle recycling line, we solved the problems of aging equipment and low production efficiency, and improved the profit of the plastic bottle recycling plant.

Introduction Of PET Bottle Recycling Line

PET bottle washing line is a production line composed of several key PET bottle recycling machines, including a conveyor belt, tumbler screen, plastic de-labeling machine, plastic bottle crusher, sink float plastic separation, hot washing tank, plastic friction washer, and plastic dryer. With coordinated cooperation, these equipments process the waste plastic bottles in multiple steps and finally transform them into high-quality PET bottle flakes, completing the transformation process from waste to resource.

PET Bottle Recycling Machine Price

Welcome to the PET bottle recycling machine price! We offer efficient and reliable recycling line equipment for your plastic bottle recycling needs. Our plastic bottle washing line is reasonably priced, depending on the volume of your needs and customization options. Whether you are building a new plastic bottle recycling plant or upgrading your existing equipment, we offer specialized solutions. Please feel free to contact us for a detailed quote and consulting services for your specific needs.

FAQ About PET Bottle Recycling Machine

What types of PET bottles can this machine process?

Our PET bottle recycling machine can handle all types of PET bottles, including beverage bottles, shampoo bottles, shower gel bottles, and so on.

What is the cleaning effect of the recycling line?

Our PET bottle washing line cleaning process is very advanced and can thoroughly remove dirt and residue from the surface of PET bottles to ensure the quality and hygiene of the final product.

What is the capacity of this PET bottle recycling line?

Shuliy’s plastic recycling washing line capacity ranges from 500-6000kg/h. The capacity of our PET bottle recycling machine can also be customized according to customer’s needs, from small to large, and flexibly adapted to the production needs of different scales. If there is any need or question, you can contact us at any time.

What do I need to pay attention to the maintenance of the equipment?

Regularly clean the surface of the plastic bottle washing line, keep the equipment well ventilated, regularly check the equipment parts, and replace the worn parts in time, which can prolong the service life of the recycling equipment.

Is there any after-sales service?

Yes, as a professional plastic recycling machine manufacturer, we provide comprehensive after-sales service, including equipment installation and commissioning, training of operators, technical support, and so on, to ensure that customers can use the equipment smoothly.